A sand box transfer device

A transfer device and sand box technology, which is applied in the direction of mold handling equipment, metal processing equipment, casting equipment, etc., to achieve the effects of reducing labor usage, reducing labor costs, and facilitating control and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

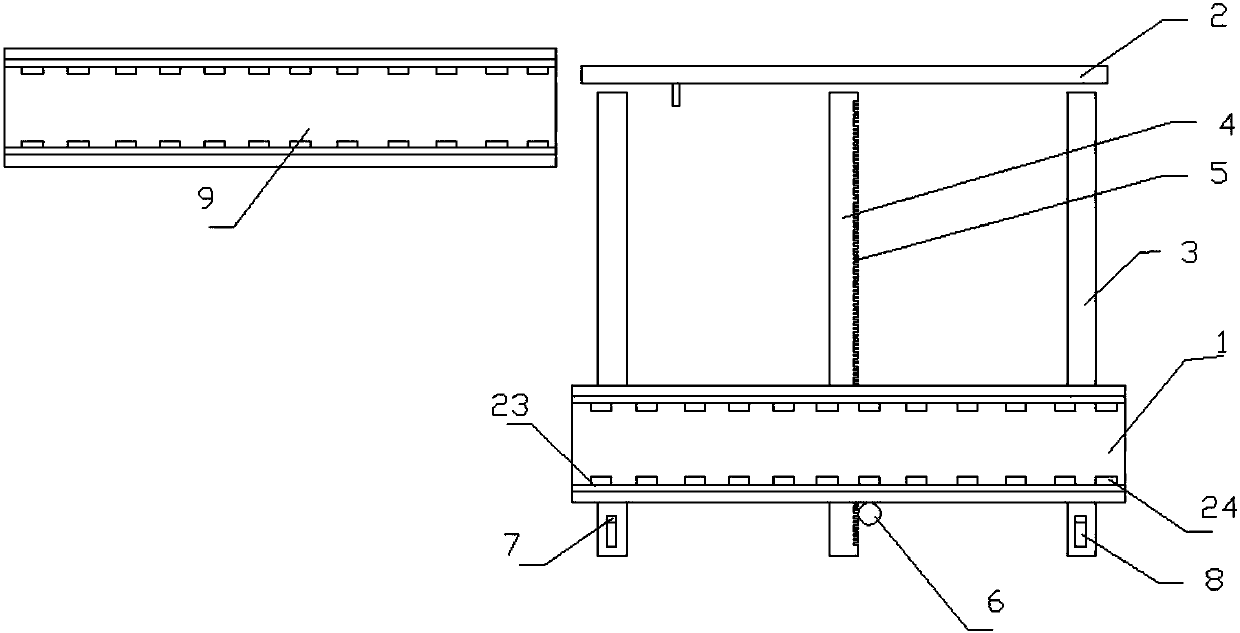

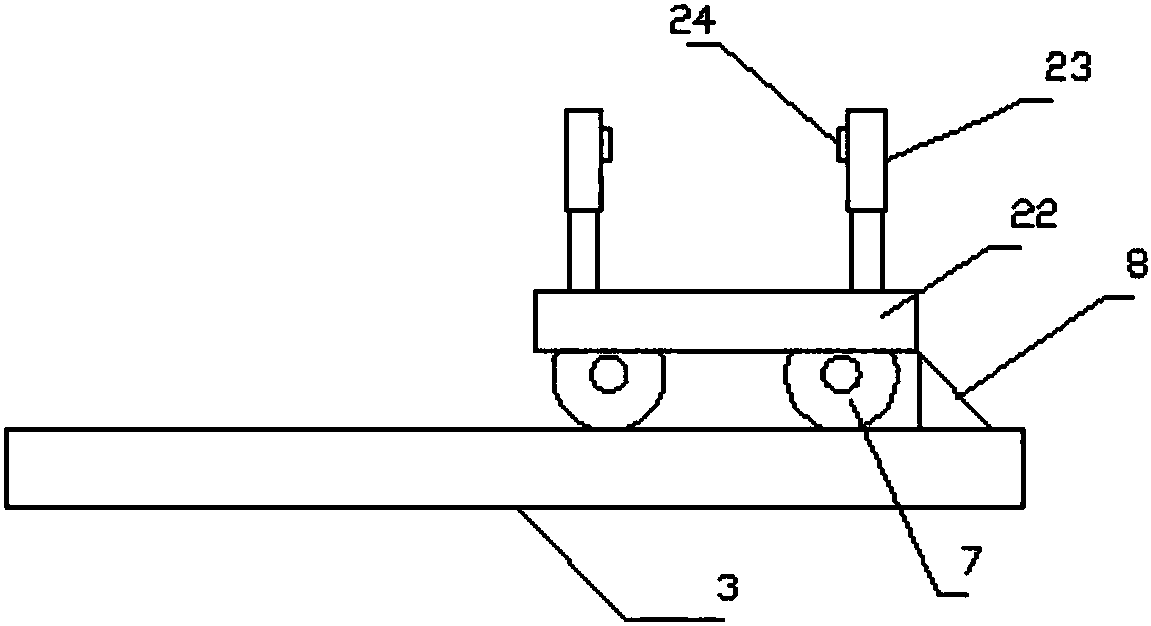

[0039] The present embodiment comprises conveying track 3, conveying trolley 1 and pushing device 2, and described conveying trolley 1 is installed on conveying track 3, and conveying trolley 1 can slide on conveying track 3, and one end of conveying track 3 is provided with described pushing Device 2, the conveying trolley 1 includes a base plate 22, rollers 7 and a transport frame 23, the rollers 7 are arranged on the bottom surface of the base plate 22, and are located in the transport track 3, the transport frame 23 is arranged on the upper surface of the base plate 22, and the transport frame 23 A plurality of transport wheels 24 are provided.

[0040] Drive track 4 is laid between conveying track 3, and drive track 4 is provided with drive rack 5, and described transport trolley 1 is provided with drive gear and drive motor 6, and described drive gear meshes with drive rack 5, and drive gear Socketed on the output shaft of the drive motor 6.

[0041] Limiting blocks are...

Embodiment 2

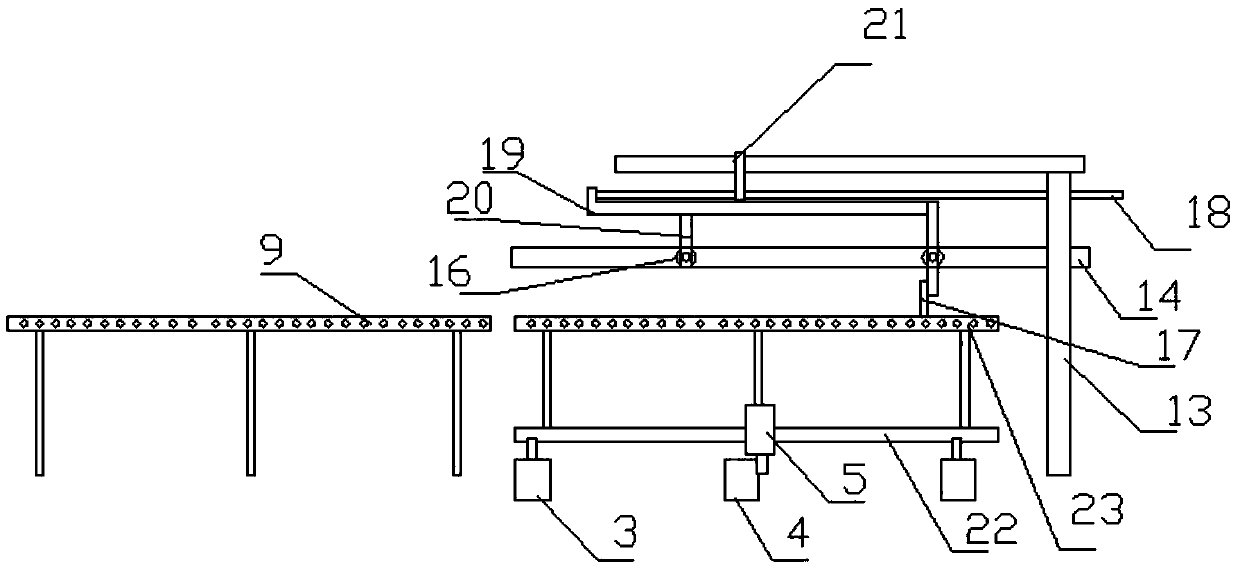

[0044] The present embodiment comprises conveying track 3, conveying trolley 1 and pushing device 2, and described conveying trolley 1 is installed on conveying track 3, and conveying trolley 1 can slide on conveying track 3, and one end of conveying track 3 is provided with described pushing Device 2, the conveying trolley 1 includes a base plate 22, rollers 7 and a transport frame 23, the rollers 7 are arranged on the bottom surface of the base plate 22, and are located in the transport track 3, the transport frame 23 is arranged on the upper surface of the base plate 22, and the transport frame 23 A plurality of transport wheels 24 are provided.

[0045] Drive track 4 is laid between conveying track 3, and drive track 4 is provided with drive rack 5, and described transport trolley 1 is provided with drive gear and drive motor 6, and described drive gear meshes with drive rack 5, and drive gear Socketed on the output shaft of the drive motor 6.

[0046] Limiting blocks are...

Embodiment 3

[0049] This embodiment is basically the same as Embodiment 1 or 2, the difference is: use the control system to control the running direction of the conveying car, the time of staying and control whether the pushing device pushes or not, the control system includes a signal collector and a controller, and the signal The collector is a proximity sensor switch or a photoelectric switch and a timer that collects whether the delivery car has reached the designated position. The controller is a PLC controller. The proximity sensor switch or photoelectric switch transmits the signal of whether the delivery car has reached the designated position to the controller. The controller controls whether the timer counts and whether the pushing device pushes according to the signal. Once the timing starts, the controller judges whether to control the drive motor to reverse according to the set time, and resets the conveying trolley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com