Pressure and displacement double-control press fitting machine

A pressing machine and pressure technology, applied in the field of mechanical processing, can solve the problems of unable to achieve the pressing effect, unable to judge the clamping force, falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

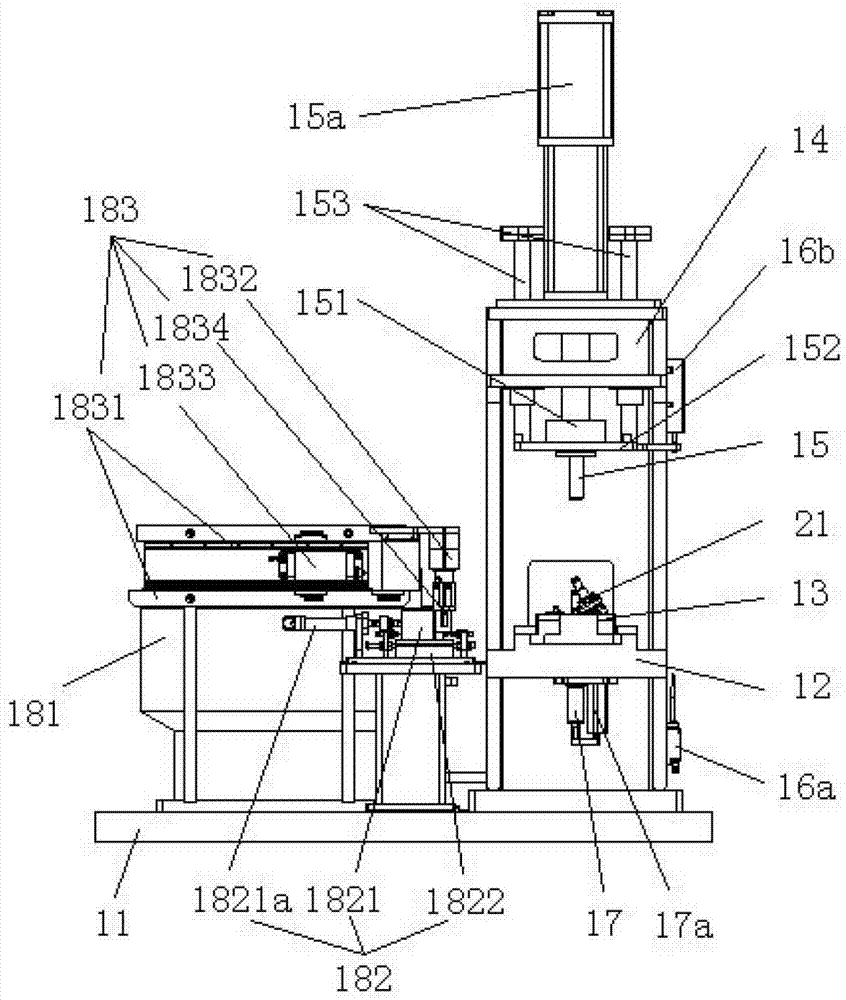

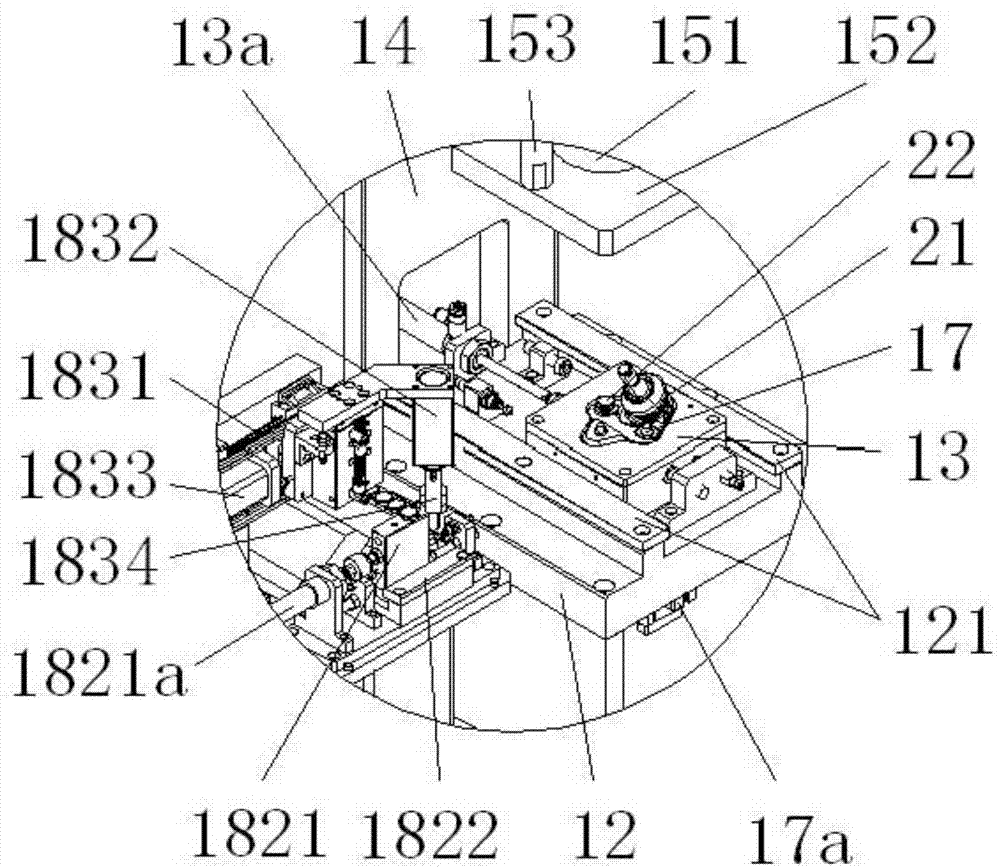

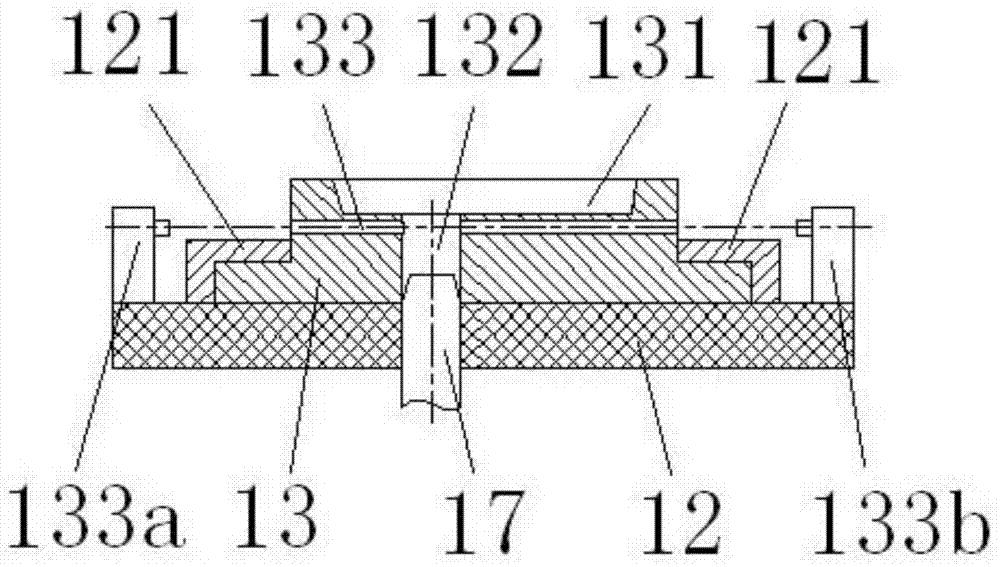

[0028] Such as figure 1 , figure 2 As shown, a pressure-displacement double-control press-fitting machine is used for the press-fitting of the ball pin seat 21 and the knurled bolt 22, which includes a machine table 11, a base 12, a carrier 13, a body 14, a first cylinder 15a and a press-fitting The punch 15, the base 12 are fixed on the machine platform 11, the carrier 13 is installed on the upper surface of the base 12, the body 14 is arranged above the base 12, the first cylinder 15a is installed above the body 14, and the press-fit punch 15 is supported by the first cylinder 15a drives and passes through the body 11; the press-fit punch 15 is provided with a pressure sensor 151, one side of the base 12 is provided with a travel switch 16a, and the side of the press-fit punch 15 is provided with a touch block 16b for contacting the travel switch 16a. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com