h type parallel robot

A robot and parallel technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of difficult control of the position accuracy of the execution part, insufficient overall structural rigidity, and high manufacturing costs, reducing the mass of the motion load and increasing the motion speed. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

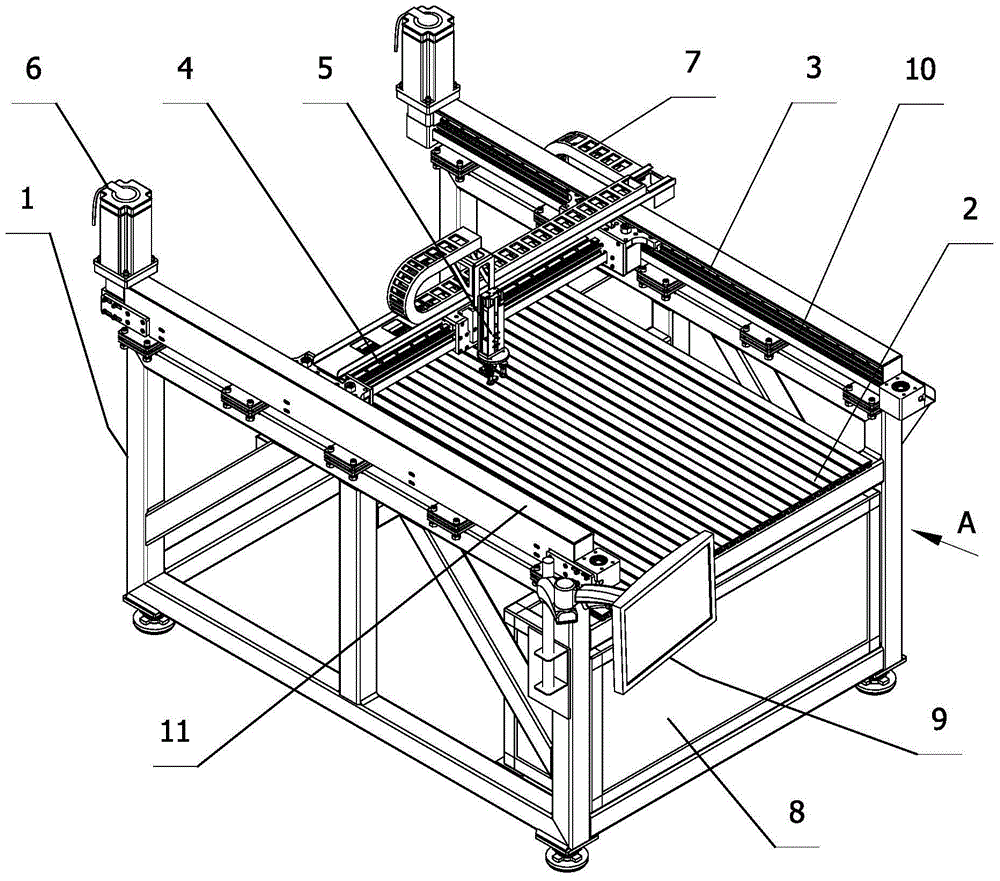

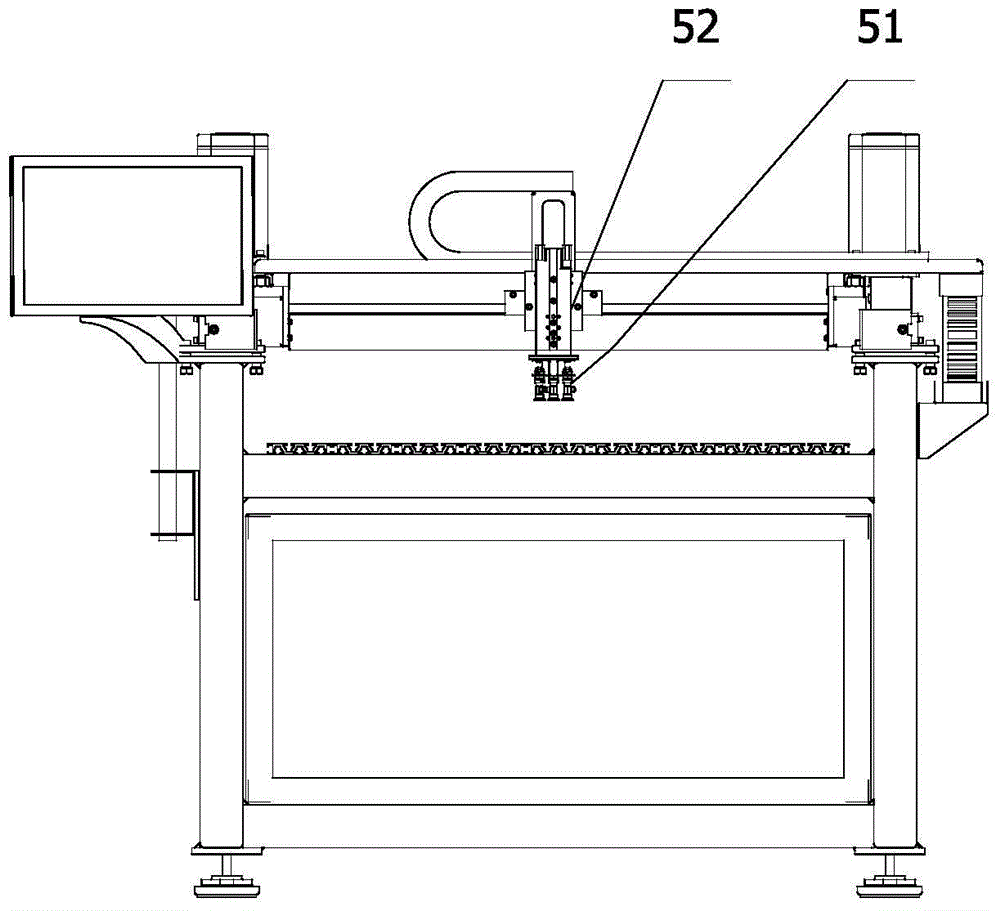

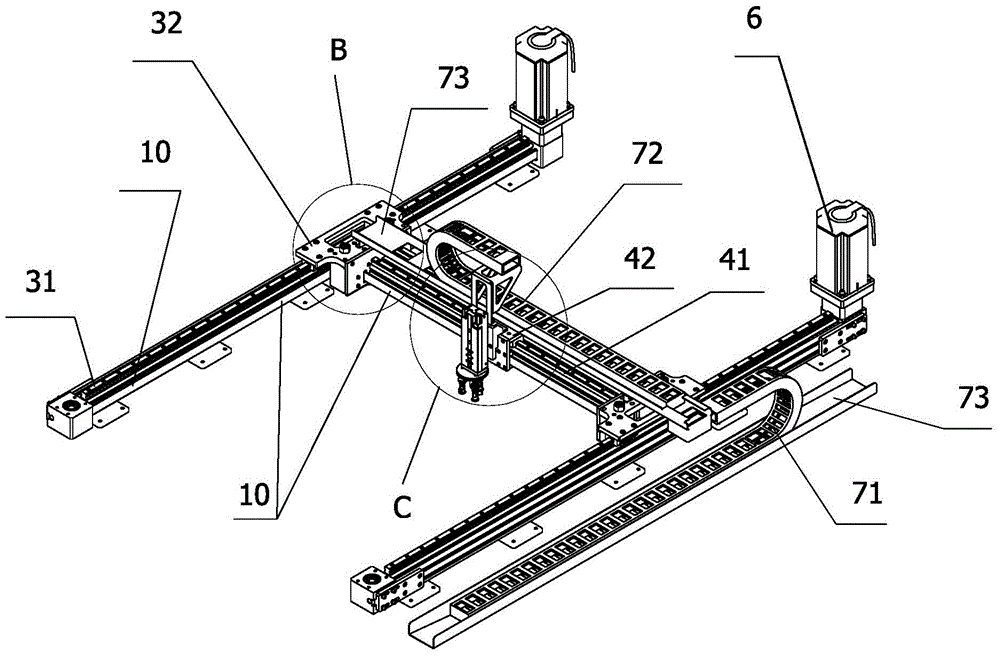

[0024] combine figure 1 —— image 3 As shown, an H-type parallel robot is mainly composed of a frame 1, a workbench 2, two X-direction components 3, a Y-direction component 4, a Z-direction component 5, two drive motors 6, a pipeline slot 7, and a timing belt 10. It consists of two active synchronous pulleys, two driven synchronous pulleys, four idler pulleys, etc. In addition, it also includes an electrical junction box 8, a display screen 9, etc.

[0025] The workbench 2 is fixed above the frame 1 , and two X-direction assemblies 3 , one Y-direction assembly 4 and one Z-direction assembly 5 are also arranged above the workbench 2 . Two X-direction components 3 are symmetrically arranged on the left and right sides of the workbench 2 . Each X-direction assembly 3 is composed of an X-direction rail 31 and an X-direction slider assembly 32 , the X-direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com