Method for discharging waste during punching of automotive interior ornament products and special die

A technology for automotive interior parts and waste discharge, which is applied in the field of mold waste discharge, can solve the problems of high requirements for waste discharge equipment, easy failure of waste ejection, time-consuming and labor-intensive mold maintenance, etc., and achieve the effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

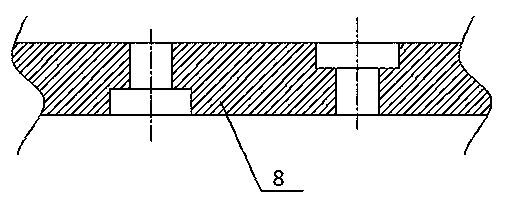

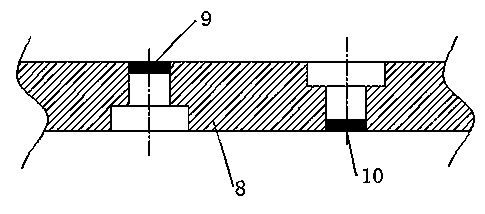

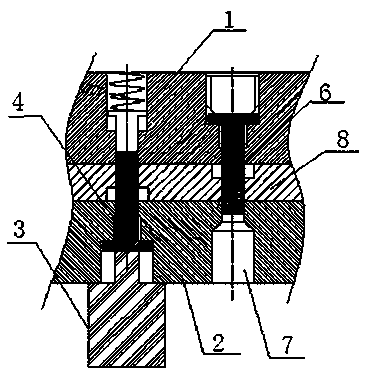

[0021] Example 1, see Figure 5 , 6 According to the design requirements, the upper mold 1 and the lower mold 2 are processed, and the product 8 to be punched is placed between the two. The cylinder 3 and the recoil head 4 are installed on the lower mold 2, and the cylinder 3 drives the recoil head 4 to move. On the upper mold 1, a compressed air chamber 5 is set up at the position corresponding to the recoil head 4, and at the same time corresponds to the position of the upper waste material 9 on the product 8, and an air pressure regulating valve is added outside the compressed air chamber 5; the punch 6 is installed on the upper mold 1, The punch 6 corresponds to the blanking hole 7 on the lower mold 2 , and corresponds to the position of the lower end scrap 10 on the product 8 at the same time.

[0022] Using the mold of the above-mentioned embodiment 1, the problem can be solved well by changing the power of waste ejection to compressed air; when the mold is in the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com