Inclined pulling assembly for 3D printing device

A 3D printing and oblique drawing technology, applied in the field of oblique drawing components, which can solve the problems of increased printing cost, easy damage, and large horizontal space of the machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

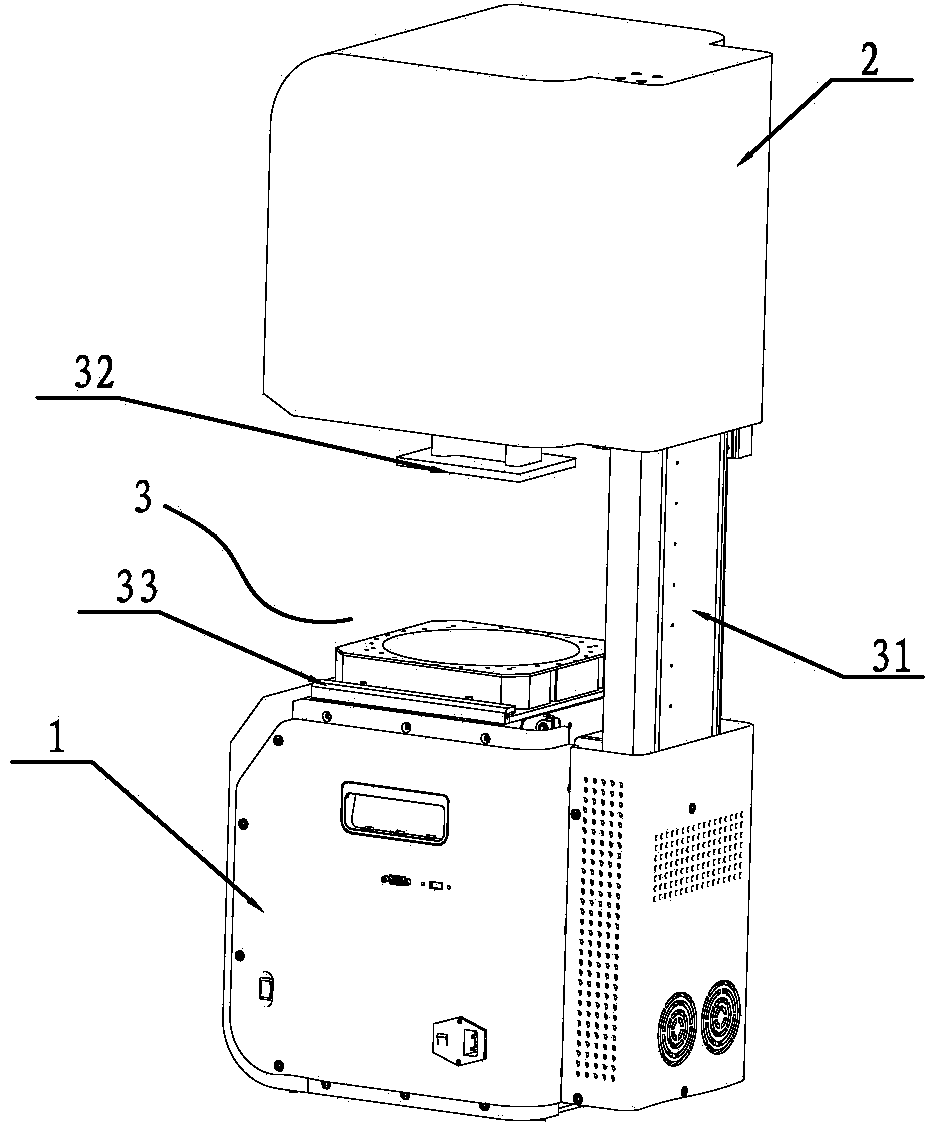

[0016] The oblique drawing assembly described in the present invention is applied to a 3D printing device, such as figure 1 As shown, the 3D printing device includes a base 1, an exposure mechanism and a control mechanism arranged in the base 1, a cover mechanism 2 and a printing mechanism 3 arranged on the base, wherein the printing mechanism 3 includes a module 31, The printing platform 32 that is slidably installed on the module 31, and the oblique drawing assembly 33 positioned at the bottom of the module 31; the module 31 is provided with a longitudinal thread, the printing platform 32 is connected with the thread, and the bottom of the thread is connected with the thread. The motors are connected, and the wire handle is driven to rotate by the wire handle motor, so that the printing platform 32 slides up and down on the module 31 . The exposure mechanism includes a projector, and the projector adopts a DLP projector.

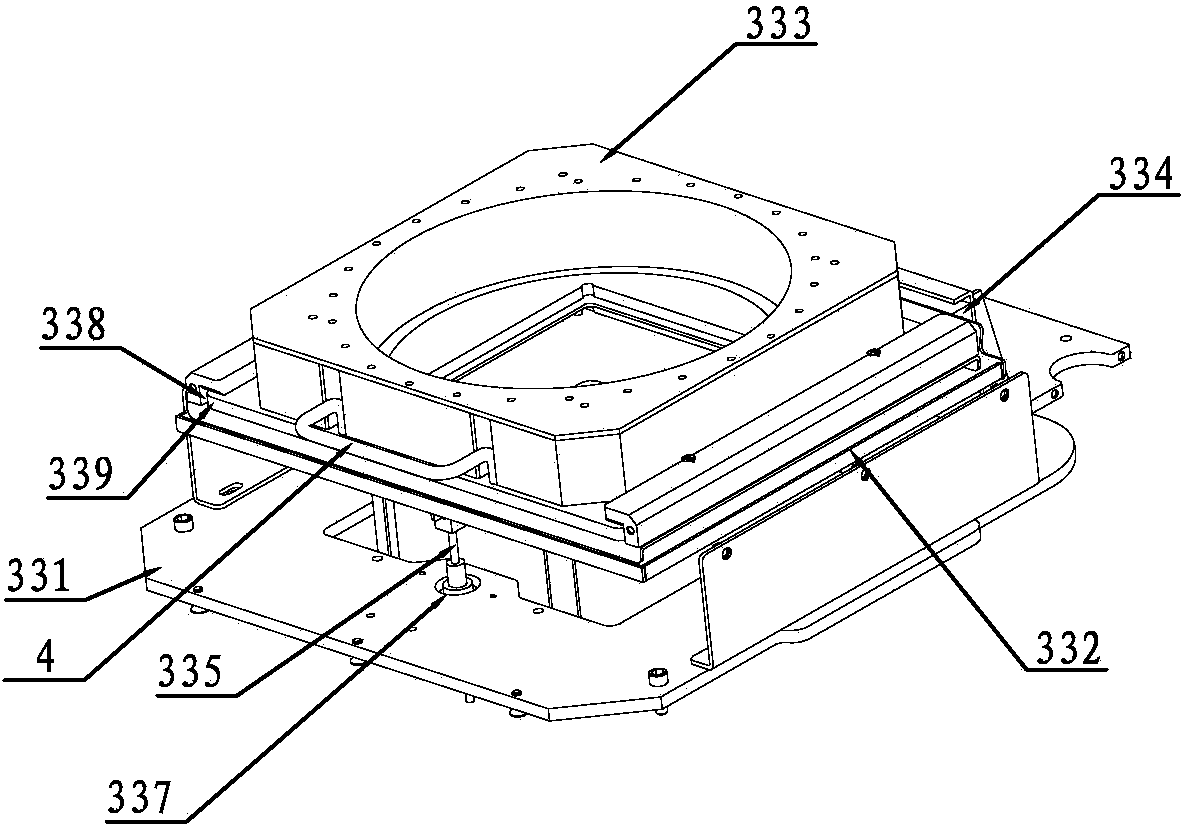

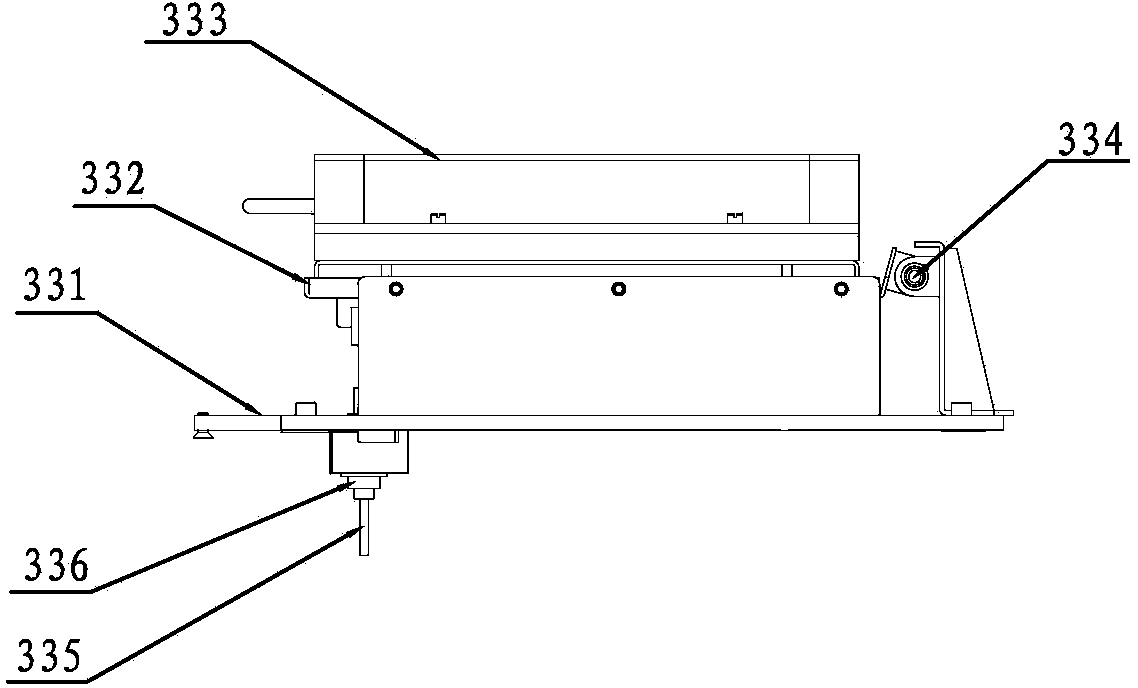

[0017] Such as Figure 2-3 As shown, the oblique d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com