Novel equal-phase multi-channel power divider

An equal-phase, multi-channel technology, applied in waveguide-type devices, electrical components, waveguides, etc., can solve the problems of large phase dispersion of the power divider, affect the phase consistency, and reduce the size of the power divider board, so as to reduce the lateral volume, The effect of increasing the vertical volume and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

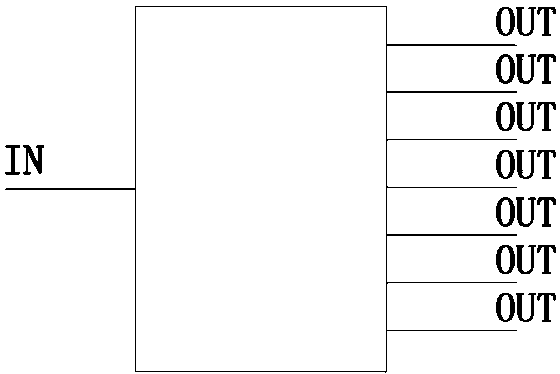

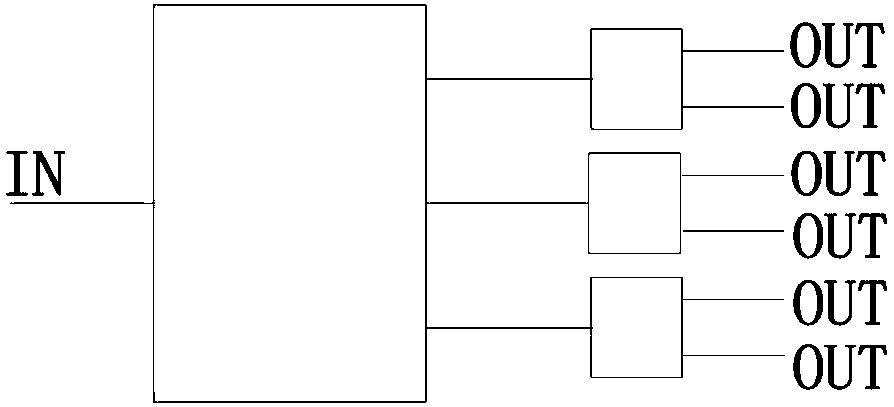

[0018] The new three-dimensional structure power divider provided in this embodiment, the internal circuit principle of the power divider is the same as that of the existing power divider circuit, and the phase consistency is realized by controlling the length of the microstrip line. This embodiment only changes the described For the structure of the power splitter board, change the existing one power splitter board to at least three power splitter boards, and determine the number of power splitter boards according to the structural requirements of the power splitter and the number of output connectors 31, such as figure 2 As shown, the power dividing board includes a first power dividing board 20 and at least two second power dividing boards 30 .

[0019] The first power splitter 20 is a side vertical power splitter, on which there is a first microstrip line with an input end and an output end, and there is only one input end of the first microstrip line, and it is connected ...

Embodiment 2

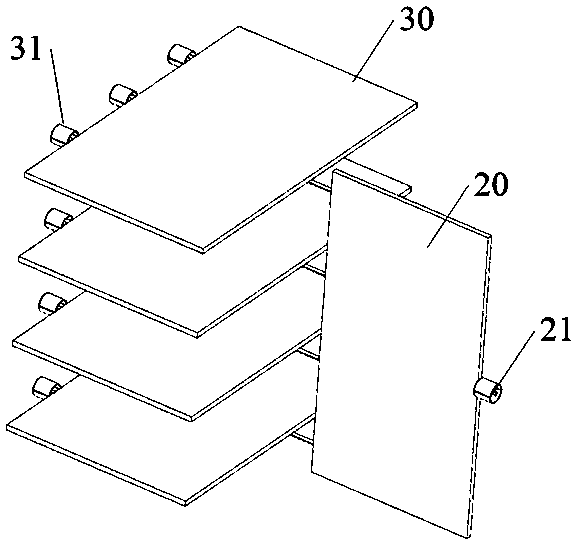

[0022] In this embodiment, a 1-point-12 (3×4) power divider is taken as an example. The power divider includes a housing 10, a first power dividing board 20 and 4 second power dividing boards installed in the housing 10 30, such as image 3 As shown, the first power dividing board 20 is provided with a first microstrip line having 1 input terminal and 4 output terminals, and the second power dividing board 30 is provided with a second microstrip line having 1 input terminal and 3 output terminals; The second power dividing board 30 is arranged parallel to and perpendicular to the first power dividing board 20, and the vertical feet of the second power dividing board 30 and the first power dividing board 20 are the output end of the first microstrip line and the input of the second microstrip line terminal connection point; and the vertical foot is welded by copper sheet, the specific power distribution board connection structure is as follows figure 2 As shown, the input end...

Embodiment 3

[0024] This embodiment is basically the same as Embodiment 2, providing a 1:12 (2×6) power divider, such as Figure 4 with Figure 5 As shown, the power divider includes a housing 10, a first power dividing board 20 and two second power dividing boards 30 installed in the housing 10, and the first power dividing board 20 is provided with one input terminal and the first microstrip line of 2 output ends, the second power dividing board 30 is provided with the second microstrip line of 1 input end and 6 output ends; The specific power dividing board connection structure is as follows figure 2 As shown, the input end of the first microstrip line is connected to the input connector 21, the output end of the second microstrip line is connected to the output connector 31, the input connector 21 and the output connector 31 are installed on the housing 10, and the output connector 31 is formed into Arranged in two rows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com