A fully automatic cloth machine for producing foamed ceramics

A technology of foaming ceramics and automatic material distribution, which is applied to ceramic molding machines, thin material processing, object supply, etc., and can solve the problems of increasing the workload of workers, reducing production efficiency, and uneven surface of powder materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

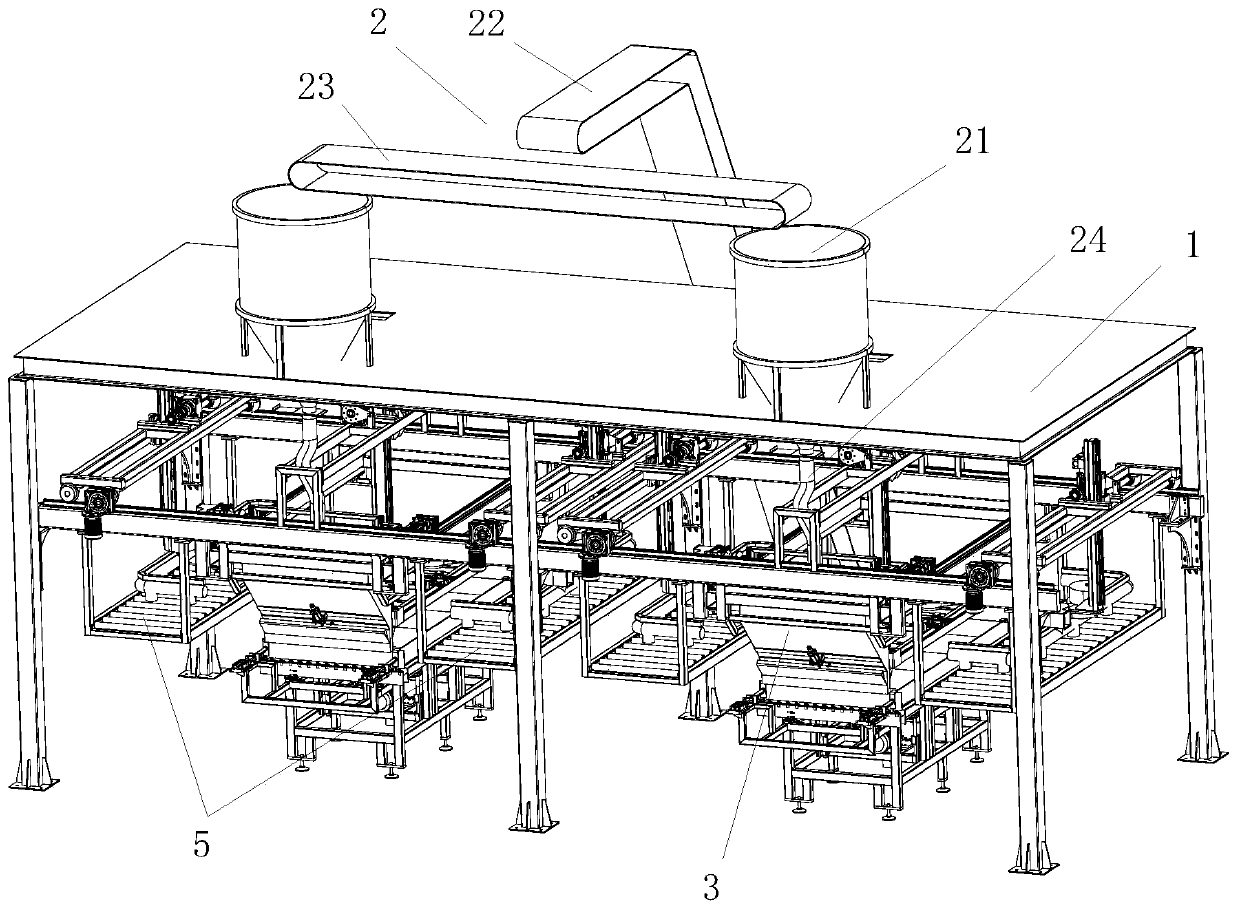

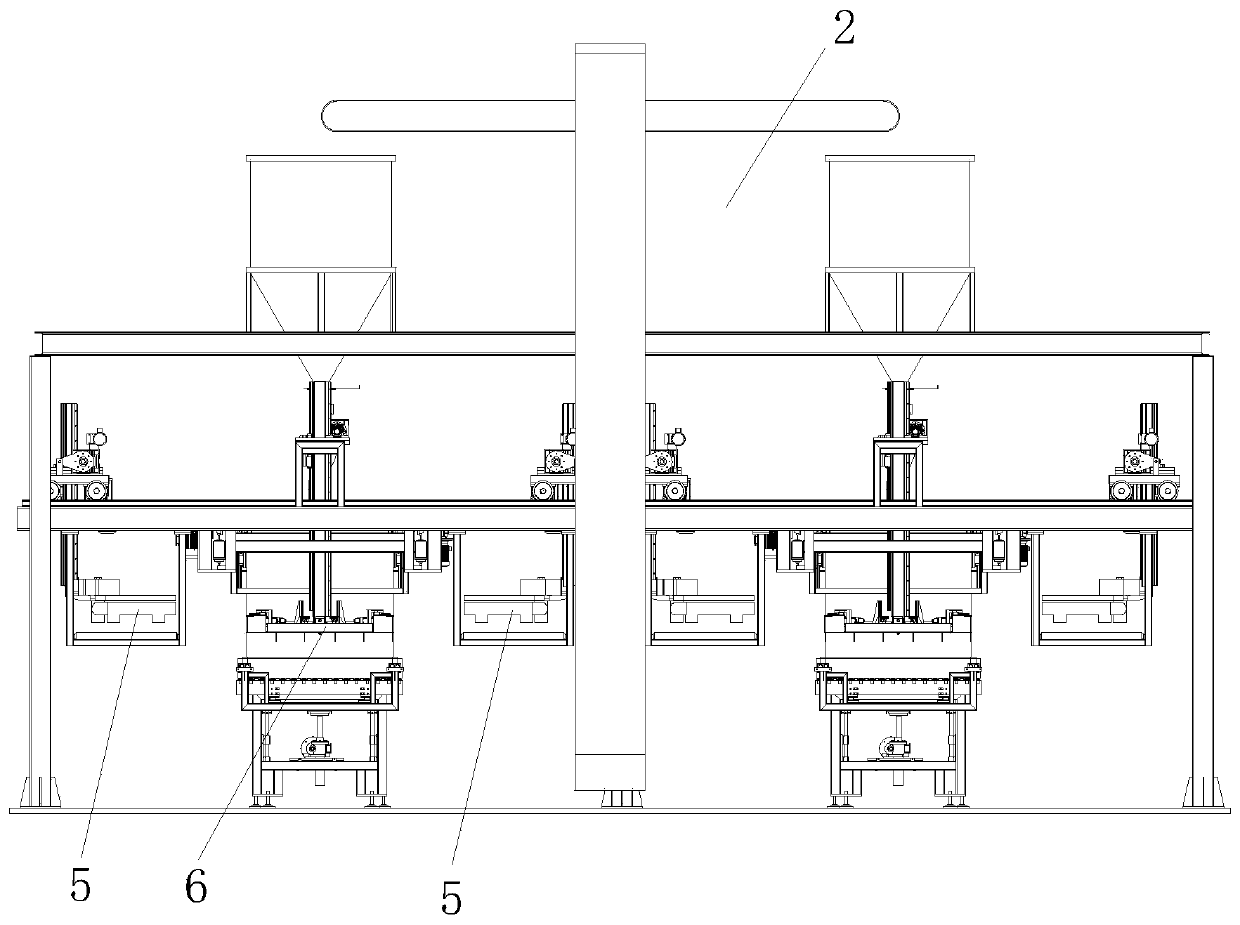

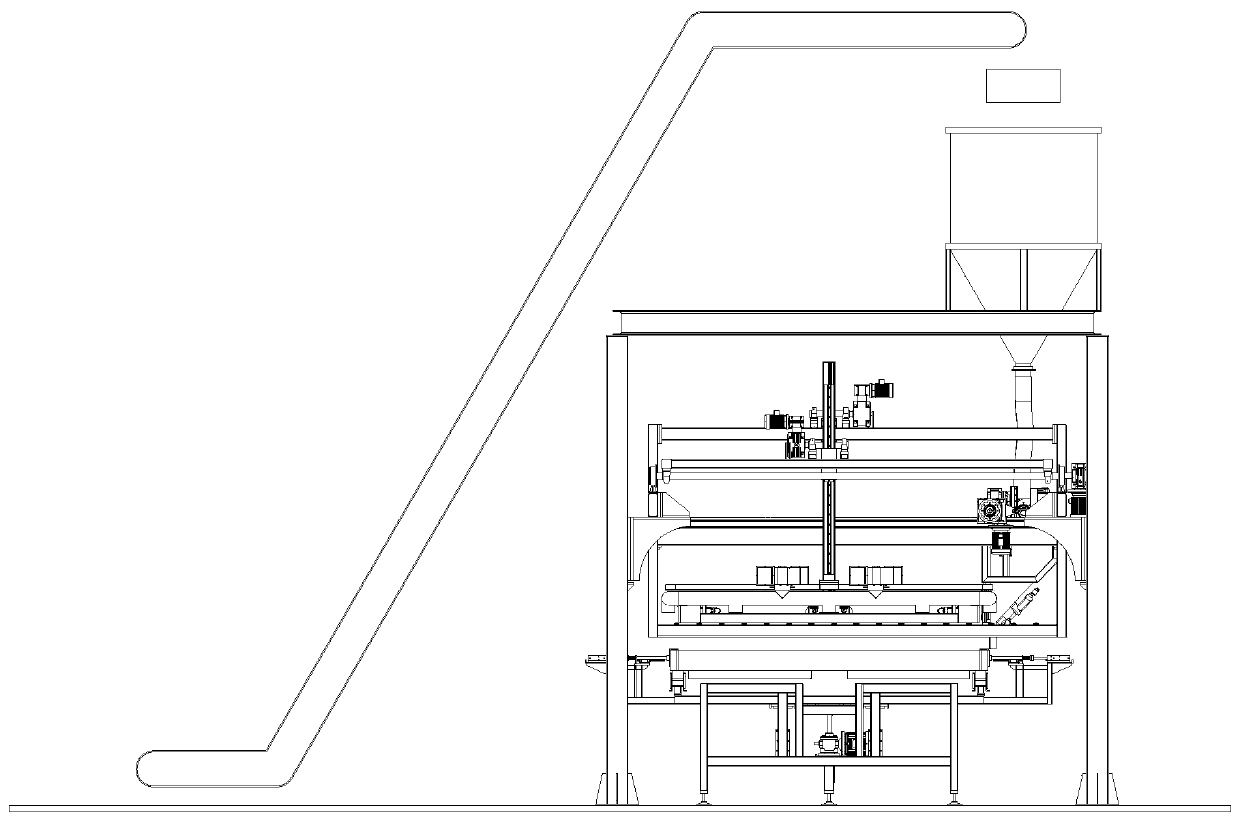

[0073] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a fully automatic distributing machine for producing foamed ceramics, the fully automatic distributing machine mainly includes a frame 1 and a material storage mechanism 2 installed on the frame 1 for storing powder , the automatic paper laying mechanism 5 for laying fiber paper on the bottom of the kiln furniture, the paper pressing mechanism 6 for pressing the fiber paper and folding it into fiber cartons, and the distribution mechanism 3 for evenly spreading the powder in the kiln furniture. The material storage mechanism 2 is located at the top of the frame 1, and its discharge end communicates with the material distribution mechanism 3. Both the distribution mechanism 3 and the paper pressing mechanism 6 are located above the distribution station, and the installation height of the paper pressing mechanism 6 is higher than that of the distribution mechanism 3 . The automatic pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com