Dyeing wastewater heat recovery device

A technology for heat energy recovery, printing and dyeing wastewater, applied in filtration circuits, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., which can solve problems such as manual cleaning, easy blockage and pollution of filters and heat exchange units , to achieve the effect of preventing clogging and reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

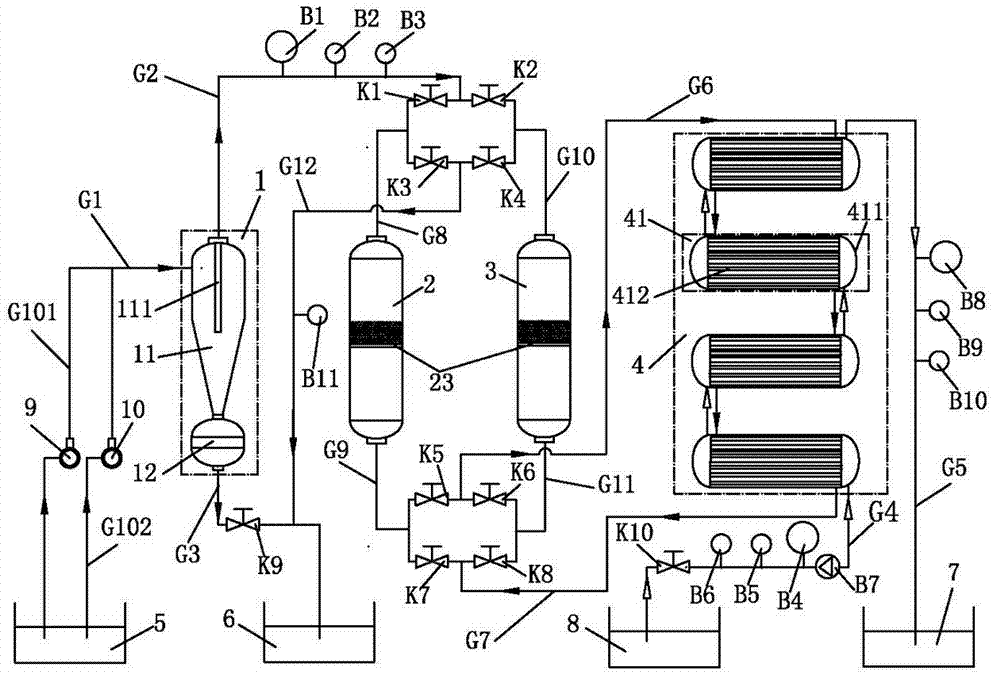

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples only represent one or several best implementation modes, and should not be construed as limiting the present invention.

[0033] Such as figure 1 Said, the printing and dyeing wastewater heat recovery device provided by the present invention includes: sequentially connected

[0034] Centrifugal filter 1 that uses high-speed rotation of water flow to remove impurities with a specific gravity greater than water in wastewater,

[0035] A first filter 2 and a second filter 3 for further filtering impurities in the wastewater,

[0036] Heat exchange system 4 that transfers heat from waste water to clean water.

[0037] The centrifugal filter 1 is provided with a centrifugal separation bin 11 and an impurity collection bin 12, the centrifugal separation bin 11 is located above the impurity collection bin 12, and the centrifugal separation bin 11 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com