Room temperature vulcanized fireproof elastomer plate and preparation method thereof

A technology of elastomeric board and room temperature vulcanization, which is applied in the field of room temperature vulcanized fireproof elastomeric board and its preparation, to achieve the effects of no irritating smell, improved fireproof performance, and low smoke production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

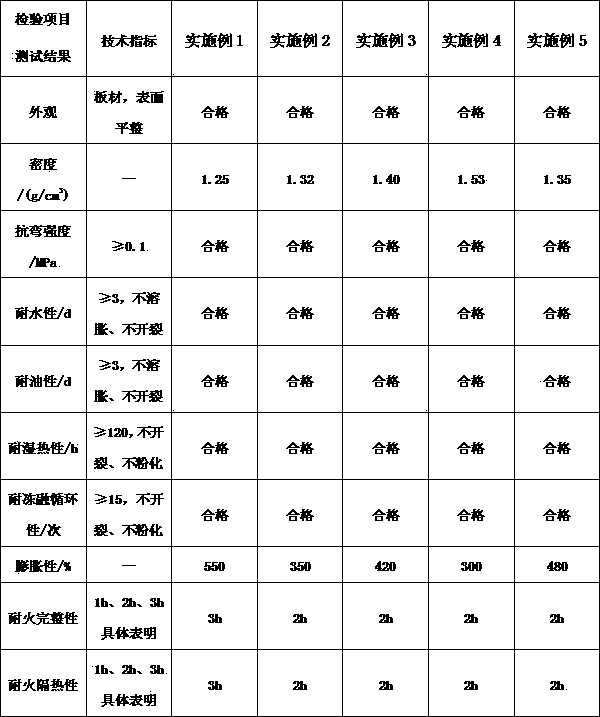

Examples

Embodiment example 1

[0036] a. Weigh each component raw material according to the following formula:

[0037] materials Dosage Hydroxy silicone oil 25% Methyltributanoximinosilane 1.5% Vinyl tributylketoxime silane 0.35% γ-Aminopropyltriethoxysilane 1.4% Dibutyltin dilaurate 0.03% Melamine 8.94% Ammonium polyphosphate 26.04% Dipentaerythritol 8.02% Aluminum hydroxide 1.4% Mica powder 3.6% wollastonite powder 6% Kaolin 3% low temperature glass powder 1.32% Zinc borate 1.5% Quartz sand 5% expanded perlite 5.7% hollow glass microspheres 1.2%

[0038] b. Add the hydroxy silicone oil, cross-linking agent, flame retardant, magnetic filler, and ceramization additive weighed in step a into the kneader in sequence, knead for 5-20 minutes at 15-45°C, and then add catalyst and coupling agent Knead with other fillers for 10 minutes to obtain a thick paste-like uniform mixture material;

[0039...

Embodiment 2

[0041] a. Weigh each component raw material according to the following formula:

[0042] materials Dosage Hydroxy silicone oil 25% Tetrabutanoximinosilane 0 0.3%.3% Vinyl tributylketoxime silane 0.35% γ-Glycidyl etheroxypropyl trimethoxysilane 1.07% Dibutyltin dilaurate 0.04% Melamine 8.2% Ammonium polyphosphate 24% Dipentaerythritol 7.4% Aluminum hydroxide 1% Mica powder 8% Kaolin 11% low temperature glass powder 0.76% Zinc borate 1.14% Quartz sand 5% expanded perlite 5.64% hollow glass microspheres 1.1%

[0043] All the other steps are described in Example 1.

Embodiment 3

[0045] a. Weigh each component raw material according to the following formula:

[0046] materials Dosage Hydroxy silicone oil 22% Vinyl tributylketoxime silane 0.75% γ-Aminopropyltriethoxysilane 0.55% γ-Glycidyl etheroxypropyl trimethoxysilane 0.70% Dibutyltin dilaurate 0.05% N-P intumescent flame retardant 19% Melamine 13.64% Ammonium polyphosphate 7.08% Dipentaerythritol 6.85% Silica powder 8% Kaolin 6% Zinc oxide 4.30% Zinc borate 1.08% Iron octanoate 0.50% expanded perlite 5% Quartz sand 3.20% meerschaum powder 1.30%

[0047] All the other steps are described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com