Thick steel plate with excellent low-temperature toughness and Rm structure of 630MPa grade and production method of thick steel plates

A technology for low temperature toughness and structure, which is used in the production of thick steel plates with an Rm of 630MPa with excellent low temperature toughness. It can solve the problems of structural damage, poor weldability, poor low temperature toughness of steel plates, etc. The effect of reducing the cold crack susceptibility coefficient and ensuring the welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

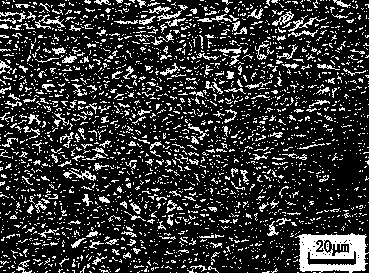

Image

Examples

Example

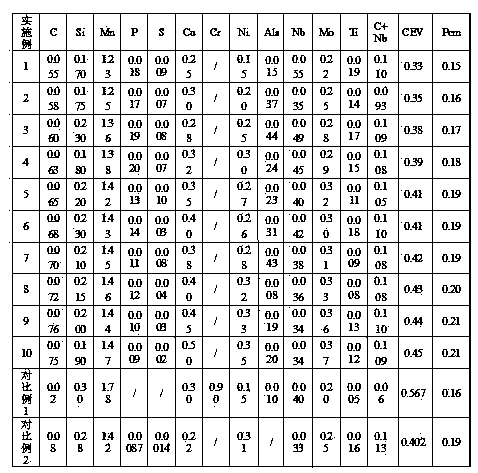

[0051] It can be seen from Table 1 that compared with Comparative Example 1, the steel of the present invention has lower Si and Mn content, no Cr in the steel, and lower CEV, which is beneficial to improve the low-temperature toughness of the steel, reduce the center segregation of the billet, and improve the weldability Compared with Comparative Example 2, the steel of the present invention has lower C, Si, Ni content, which is beneficial to improve the low-temperature toughness of the steel, and the reduction of the precious element Ni can also save manufacturing costs. Regardless of Comparative Example 1 or Comparative Example 2, the value of [C]+[Nb] is not within the range of 0.90~0.11% stated in the present invention, which shows that the comparative documents do not fully understand the effect of the ratio of C and Nb in steel .

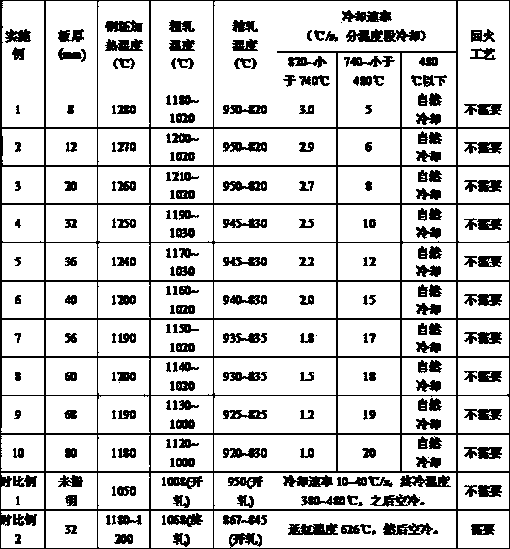

[0052] It can be seen from Table 2 that Example 1 does not specify the thickness of the steel plate, and the thickness of Example 2 is 32 mm, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com