Welded can body, welded can, method for manufacturing welded can body, and method for manufacturing welded can

A manufacturing method and technology for tank bodies, which are applied in manufacturing tools, welding equipment, roller electrode welding, etc., can solve the problems of reduced adhesiveness of resin coating, low corrosion resistance, easy penetration, etc., to improve weldability, The effect of improving corrosion resistance and reducing electrical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

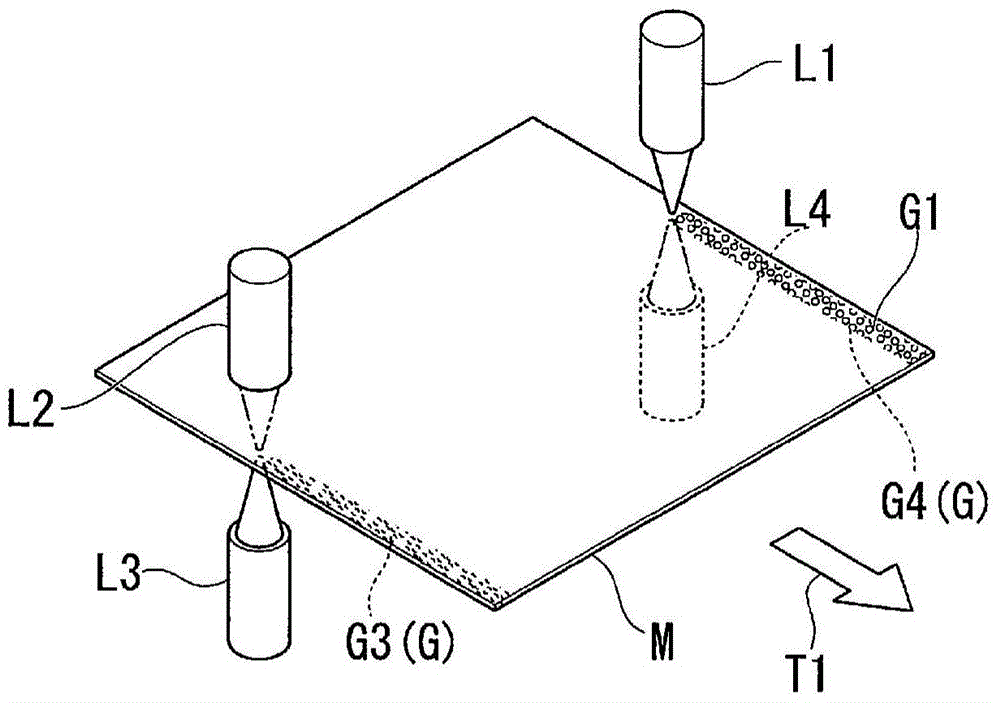

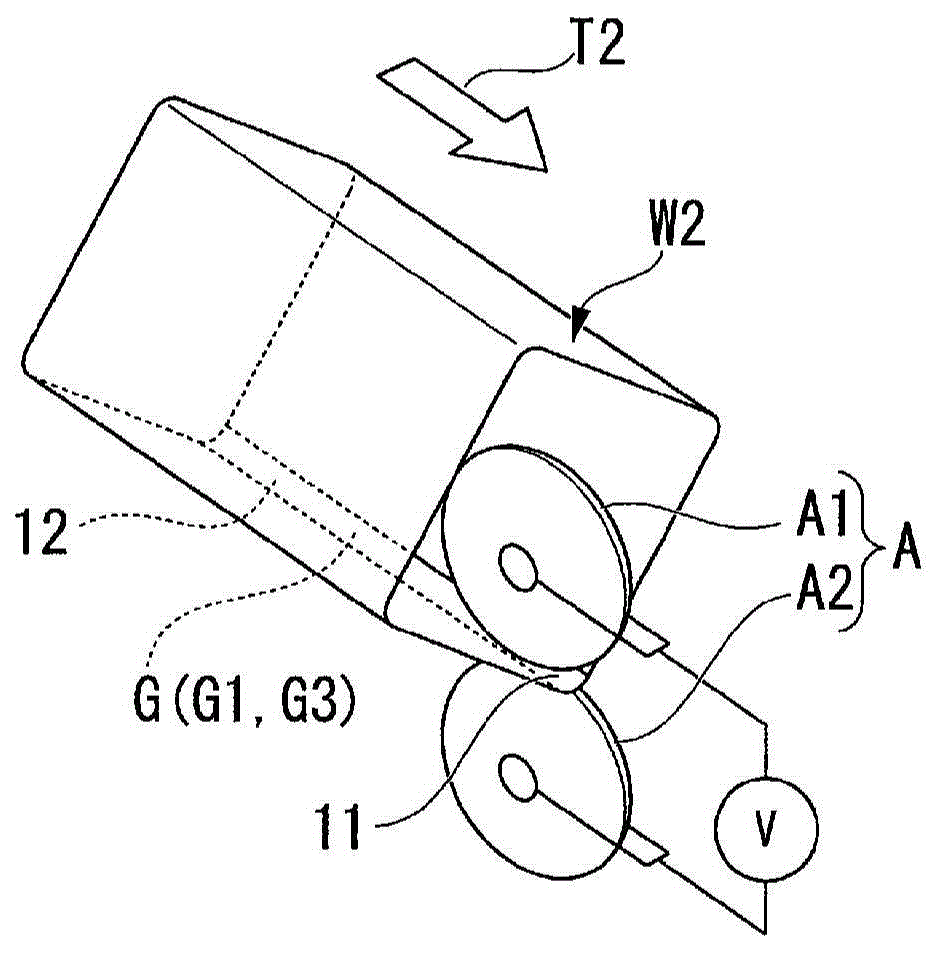

[0073] Below, refer to Figures 1 to 8B A first embodiment of the present invention will be described.

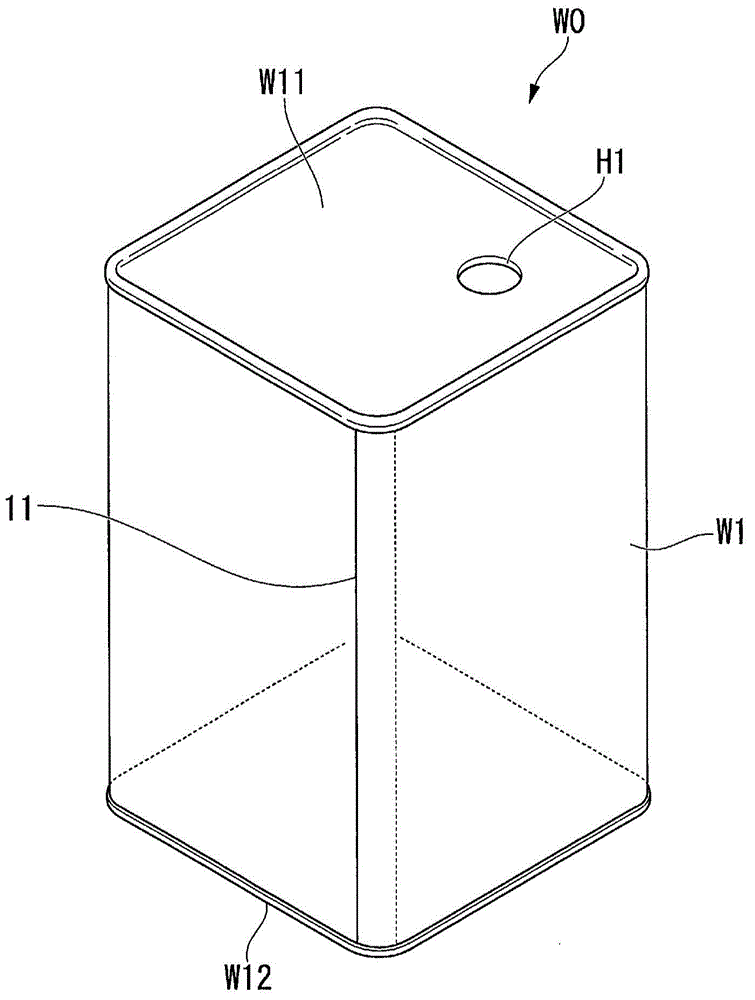

[0074] figure 1 It is a diagram showing a schematic configuration of a can body according to the first embodiment of the present invention, and symbol W0 denotes a square can such as an 18L square can (Square Can) (welded can), symbol W1 denotes a welded can body, and symbol 11 denotes a welded can body the welding part.

[0075] Such as figure 1 As shown, the rectangular can W0 includes, for example, a cylindrical can body W1, a top plate W11, and a bottom plate W12, and the top plate W11 and the bottom plate W1 are attached to openings at both ends of the welded can body W1.

[0076] A hole H1 for filling the contents into the square tank W0 or letting the contents flow out is formed in the top plate W11.

[0077] In addition, the can body W1 is joined by, for example, bending a formed material steel plate, overlapping the edges of corresponding sides, and performing ...

no. 2 approach

[0134] Below, refer to Figure 9A ~ Figure 9D A second embodiment of the present invention will be described.

[0135] Figure 9A It is a schematic diagram showing the structure of the laser irradiation part of the laser processing part G of the material steel plate used in the welded tank body of the second embodiment, Figure 9B ~ Figure 9D It is a schematic diagram explaining the modified example of 2nd Embodiment. Figure 9A ~ Figure 9D Herein, for example, the longitudinal direction of the laser processed portion G is represented by Y, and the width direction is represented by X.

[0136] The laser processing part G of the second embodiment is constituted, for example, as follows: Figure 9A As shown, a plurality of laser irradiation units 13 having a predetermined length in the Y direction are arranged in the X direction, and a plurality of laser irradiation units 13 adjacent to the X direction are arranged in a manner to be staggered by half a pitch from each other i...

no. 3 approach

[0142] Below, refer to Figure 10 A third embodiment of the present invention will be described.

[0143] Figure 10 It is a figure explaining the schematic structure of the arrangement|positioning of the laser-processed part G on the material steel plate M at the time of seam welding the part to be welded 12 in the manufacturing process of the welded tank body of 3rd Embodiment.

[0144] The third embodiment is different from the first embodiment in that, in the first embodiment, the laser processing parts G1 and G3 are formed on both surfaces constituting the electrode contact surface of the part to be welded 12, whereas in the In the third embodiment, laser processed portions G1 and G3 are formed on both surfaces constituting the electrode contact surface.

[0145] In addition, in the third embodiment, the laser processed portions G2 and G4 are also formed on both surfaces constituting the joint surface on the interface side of the material steel sheets M to be joined, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com