Protection method of high nitrogen austenitic stainless steel welded joint

A high-nitrogen austenitic and welded joint technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of joint performance degradation and achieve the effect of improving weldability and ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

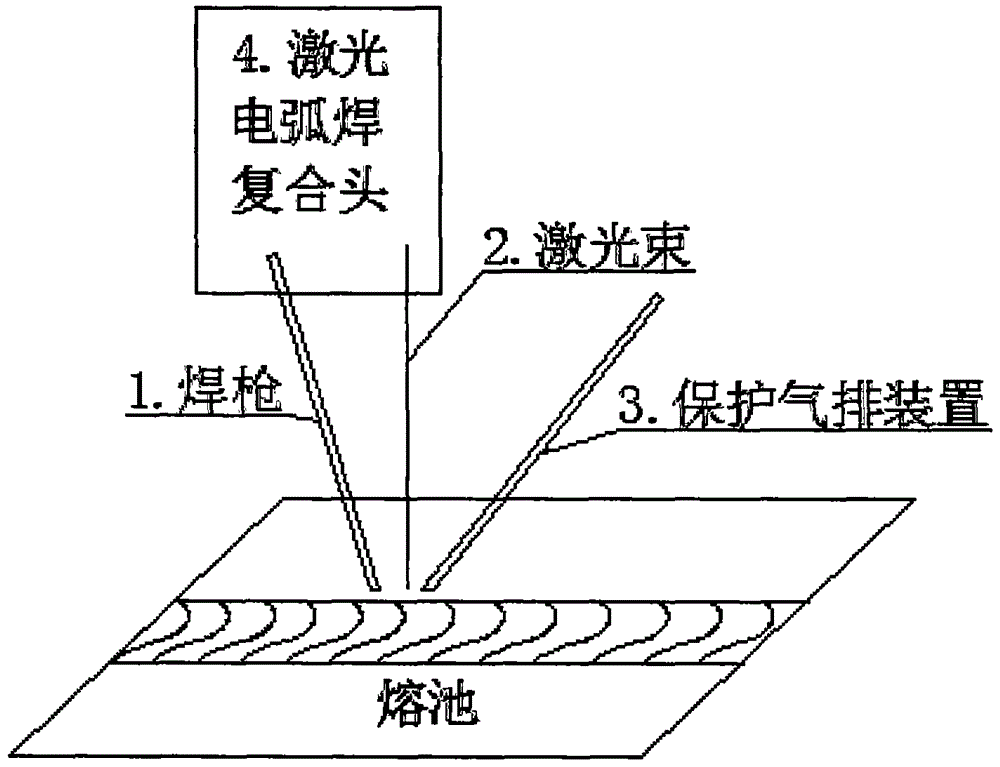

[0011] Such as figure 1 As shown, outside the composite laser arc welding head 4, a protective gas exhaust device 3 is added coaxially with the laser beam 2 and welding torch 1, and the protective gas exhaust device 3 is fed with pure argon, and the electromagnetic valve reserved for the laser arc composite welding system connection to realize welding synchronous control, that is, add argon to the original argon-carbon dioxide mixed gas shielding gas for gas protection. produce.

[0012] The following is the 8mm high nitrogen steel laser arc hybrid welding process:

[0013] The welding method is high-energy beam laser-arc compound heat source welding, the thickness of the welding base metal is 8mm, the Y-shaped groove, the blunt edge height is 4mm, the root gap is 0.5mm, the groove angle is 30°, the arc is in front and the laser is in the back. , The light filament distance is 3mm. The filling welding material is HCr20Ni10Mn7Mo welding wire with a diameter of 1.2mm; the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com