High-tidal-range sea area draught fan multi-pile cap foundation integrated mooring system

A technology of pile caps and sea areas, which is applied in the field of multi-pile cap foundation integrated berthing systems for wind turbines in high tidal range sea areas, can solve complex installation, inconvenience for staff to climb and safety, and reduce the service life of cap berthing devices, etc. problems, to achieve the effect of simple operation, labor-saving, reduced damage, and convenient climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

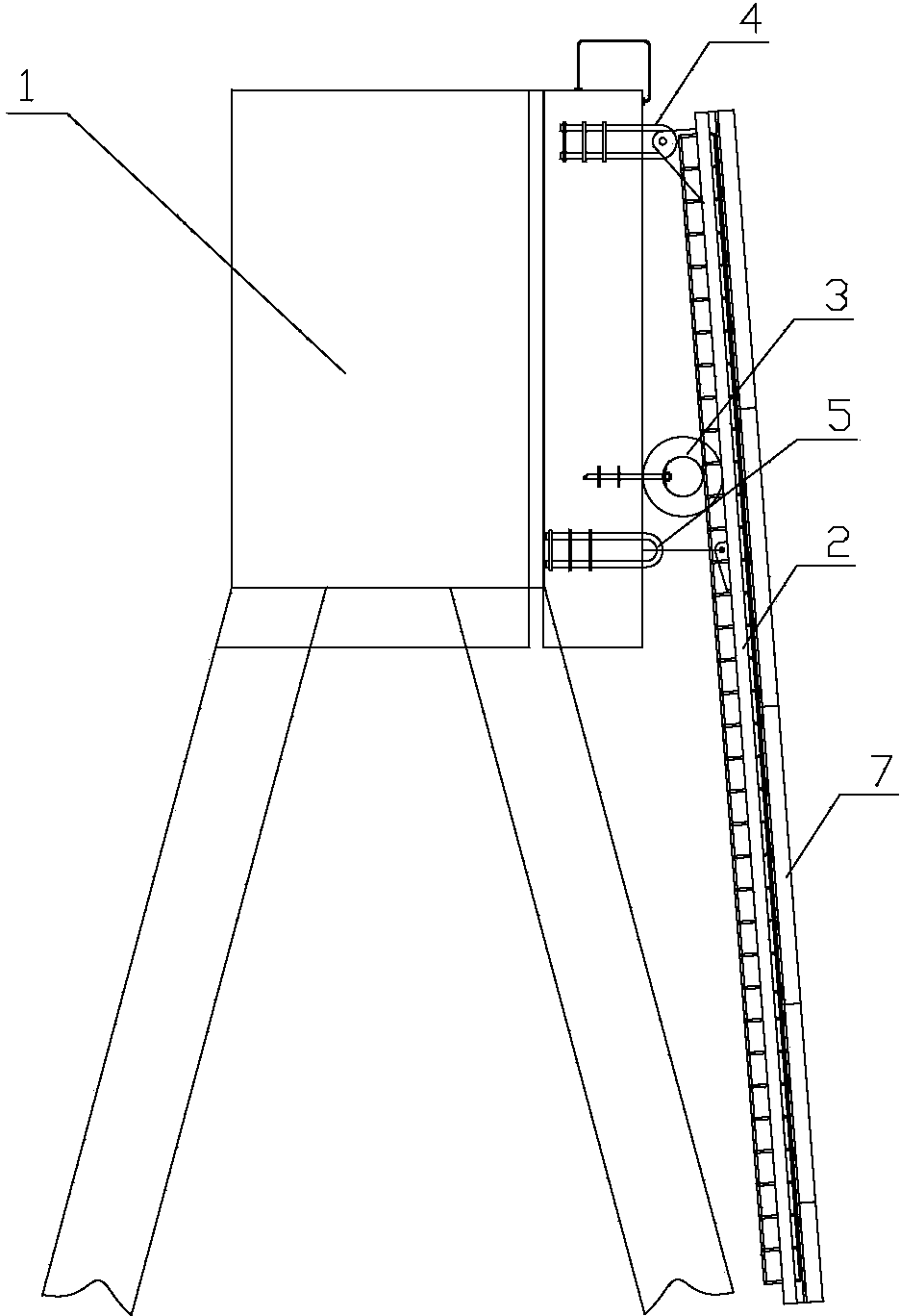

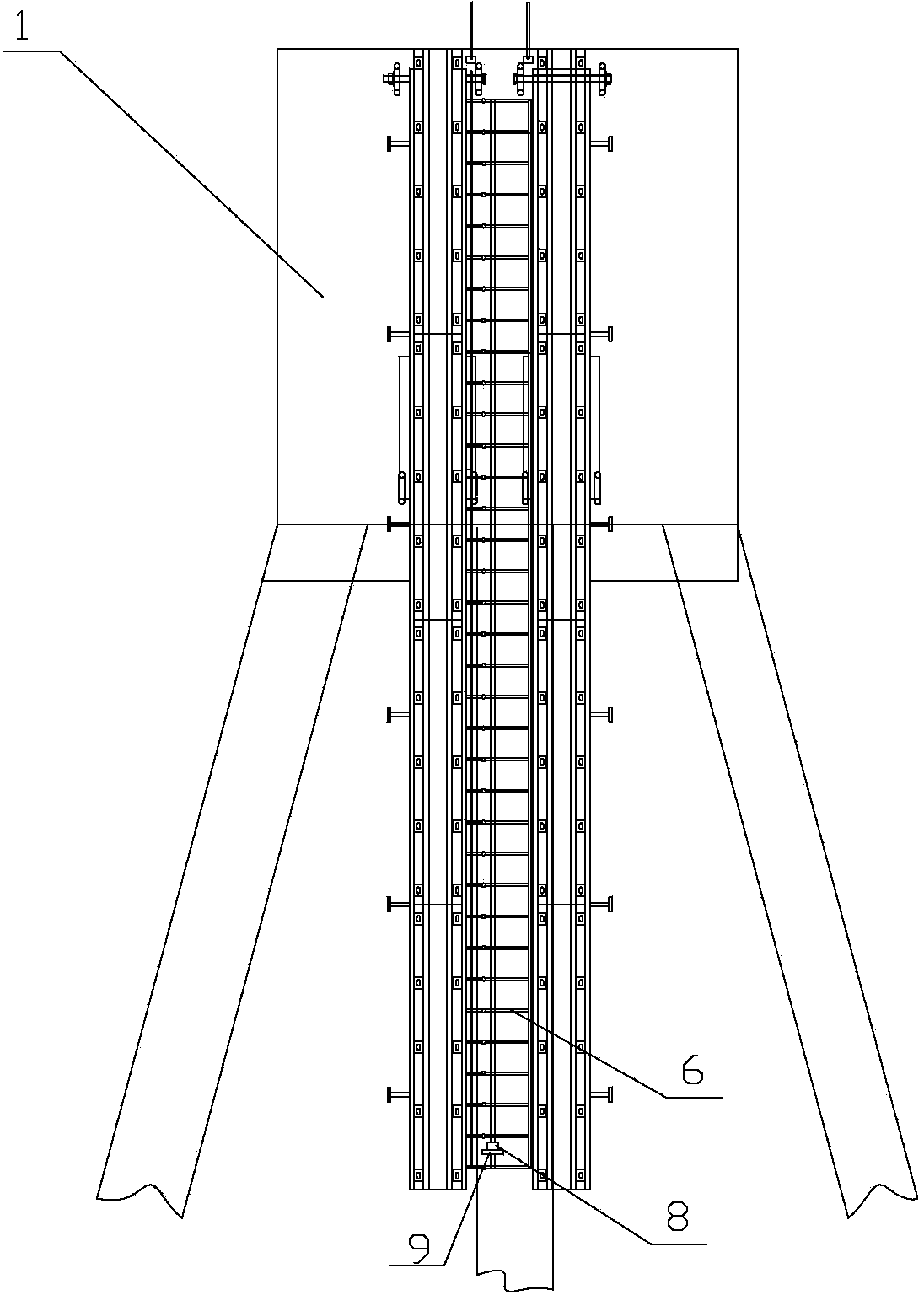

[0018] Such as figure 1 , 2 As shown, the integrated mooring system for multi-pile cap foundations of wind turbines in high tidal range sea areas includes wind power pile foundation 1 and anti-scour plate 2, and anti-scour plate 2 is separated from wind power pile foundation 1. The pile foundation 1 forms an included angle of 4 degrees. An upper U-shaped ring 4 and a lower U-shaped ring 5 are respectively fixed on the upper and lower sides of the wind power pile foundation 1, and the upper U-shaped ring 4 is axially connected with the top of the anti-shock plate 2; the lower U-shaped ring 5 and the anti-shock plate 2 move through chains Link. A rubber spring 3 is fixedly arranged on the wind power pile foundation 1 between the upper U-shaped ring 4 and the lower U-shaped ring 5 . A climbing ladder 6 is fixedly arranged in the middle of the anti-shock pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com