Thin-wall square box anti-floating structure and construction method thereof

A construction method and square box technology, applied to building components, building structures, floor slabs, etc., can solve the problems of large number of formwork holes, poor anti-floating effect, and low formwork turnover times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

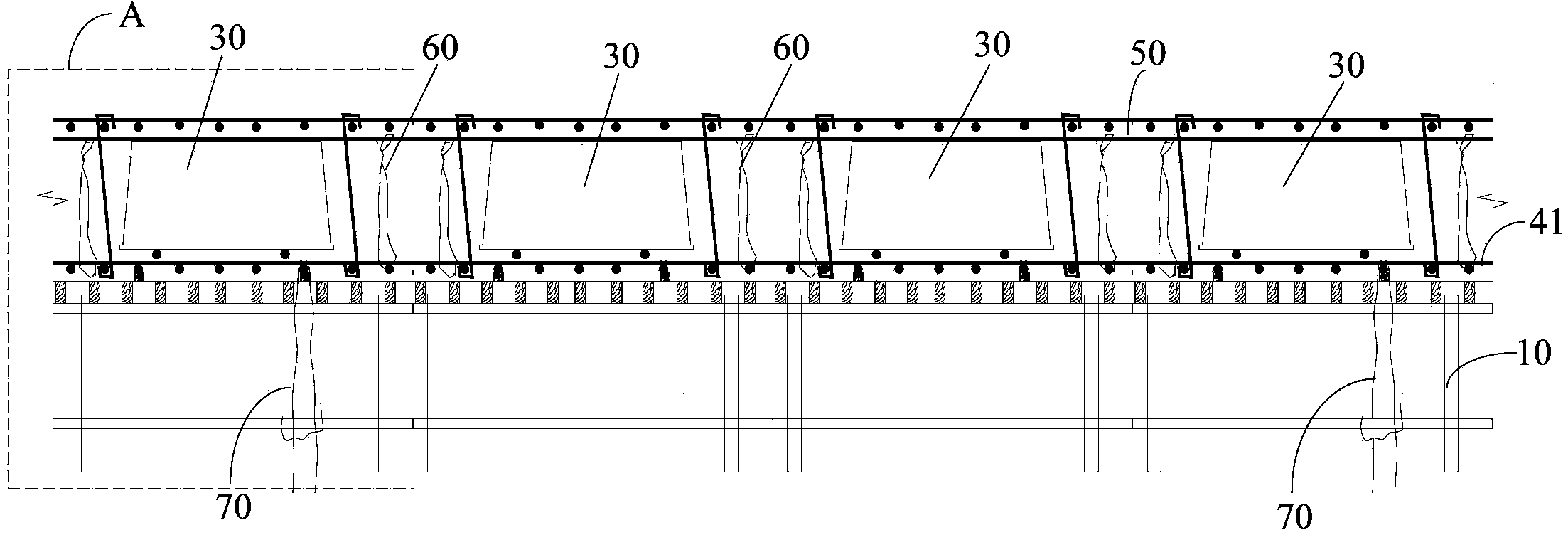

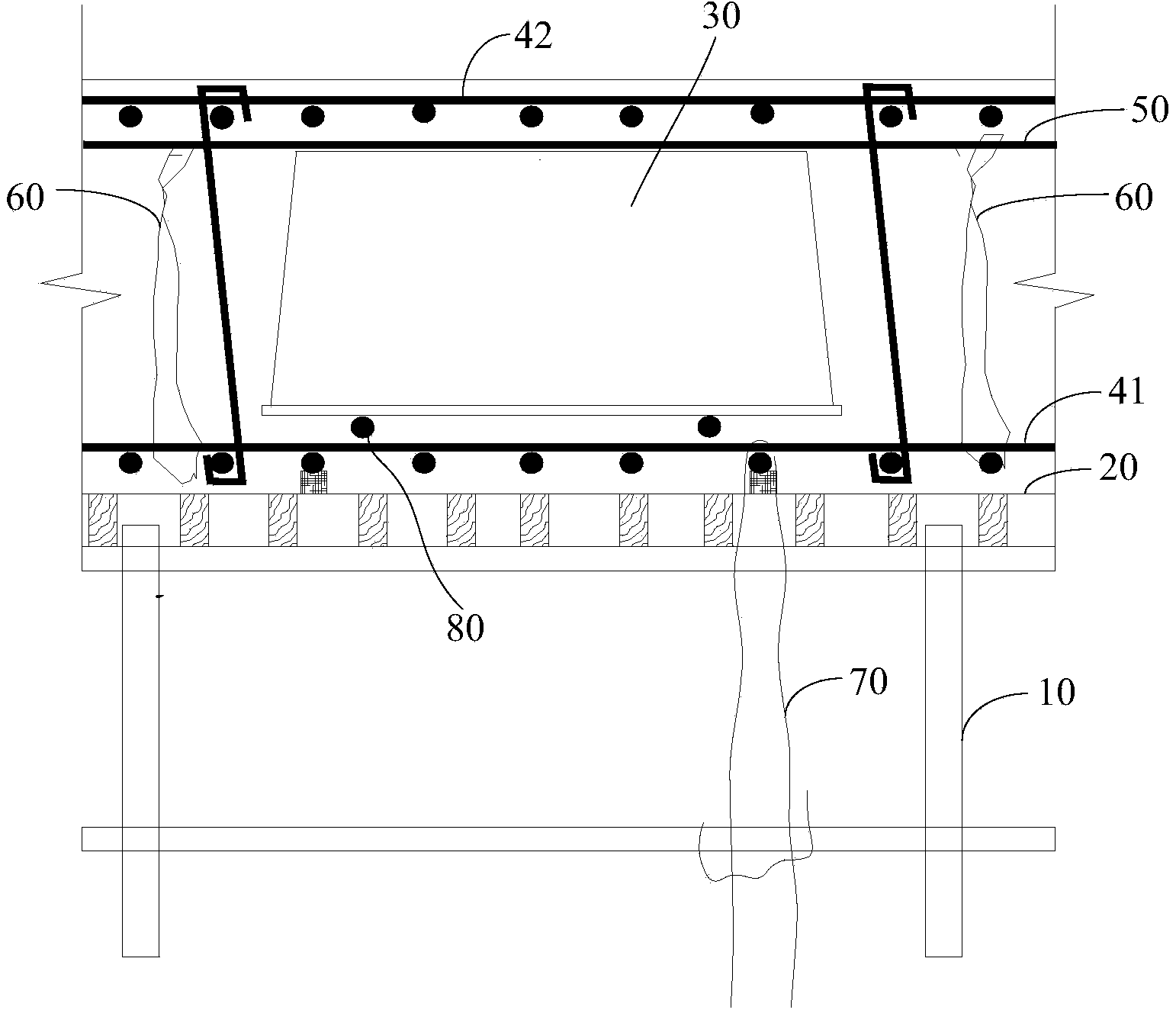

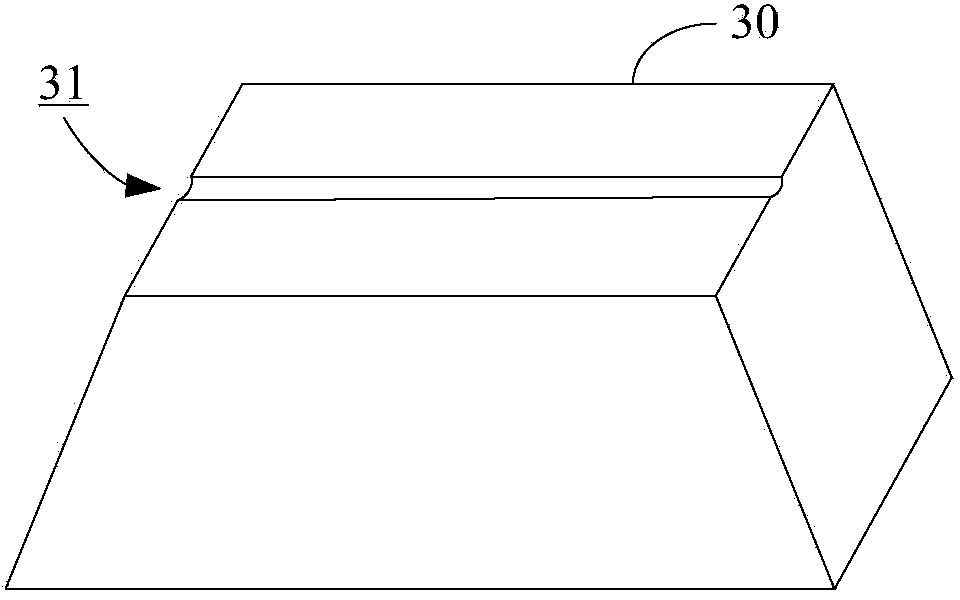

[0025] combine Figure 1 to Figure 3 As shown, the present invention provides a thin-walled square box anti-floating structure, including: a floor support frame 10, on which a formwork 20 for concrete pouring is provided, and a plurality of Hollow thin-walled square boxes 30, these thin-walled square boxes 30 are arranged in an array, the size and shape of each thin-walled square box 30 are the same, and the spacing is the same, so that after the concrete is poured, the gaps between the thin-walled square boxes 30 form multiple "rib beams", so that after pouring The appearance is relatively flat.

[0026] Bottoms of the plurality of thin-walled square boxes 30 are also provided with a bottom plate reinforcement 41, corresponding to the bottom plate reinforcement 41, the panel reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com