Jet pump with variable area ratio

An area ratio, jet pump technology, applied in the field of jet pumps, can solve problems such as occupying and destroying the flow field in the core area of the jet, and the disorder of the jet flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

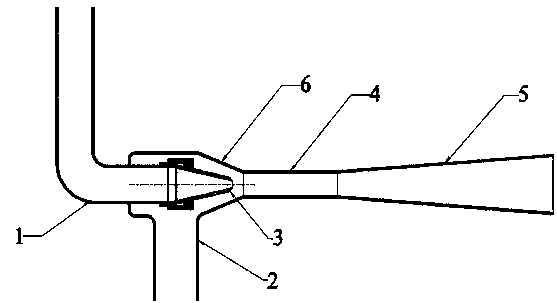

[0023] figure 1 It is a schematic diagram of a variable area ratio jet pump. As can be seen from the figure, the working liquid enters the variable outlet nozzle 3 through the water inlet pipe 1. The high-speed fluid forms a low pressure at the nozzle, and the pumped liquid enters the suction chamber 6 from the water suction pipe 2. Two streams The liquid is mixed in the throat pipe 4 for energy exchange, and finally enters the diffuser pipe 5 to be pressurized and then discharged from the jet pump; by adjusting the outlet section variable nozzle 3 to the required outlet area, the area ratio of the jet pump is controlled to make the jet pump in the high-efficiency area Work.

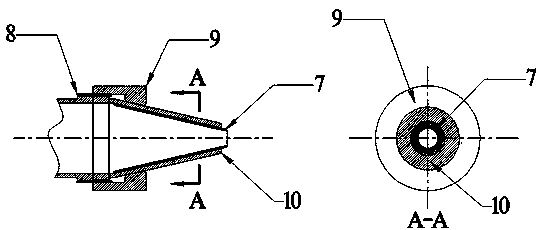

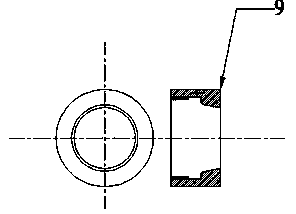

[0024] figure 2 It is a schematic diagram of a nozzle with a variable outlet section. When the working condition of the jet pump changes and the area ratio needs to be increased, the threaded locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com