A jet pump with adjustable area ratio

A technology of area ratio and jet pump, which is applied in the field of jet pump, can solve the problems of increasing cost, prone to cavitation, jet flow field disorder, etc., and achieves the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

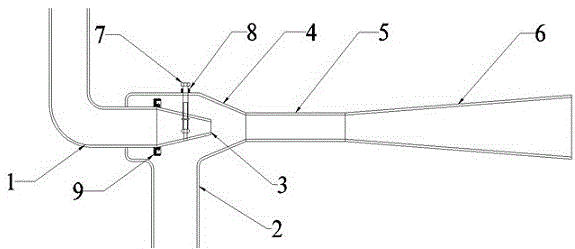

[0021] figure 1 It is a schematic diagram of a jet pump with adjustable area ratio. As can be seen from the figure, the working liquid enters the nozzle ring hinge mechanism 3 through the water inlet pipe 1. The high-speed fluid forms a low pressure at the nozzle, and the sucked liquid enters the suction chamber 4 from the water suction pipe 2. Two streams After the liquid is mixed, it enters the throat pipe 5 for energy exchange, and finally enters the diffuser pipe 6 for pressurization and then exits the jet pump. The area ratio of the jet pump is changed by adjusting the area of the nozzle 3 through the ring locking device 7, so as to adjust the flow rate of the mixed liquid and pressure, the device is dynamically sealed through the shaft seal 8 and the lip seal ring 9.

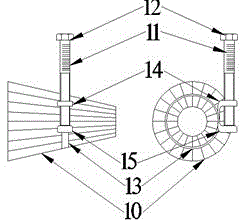

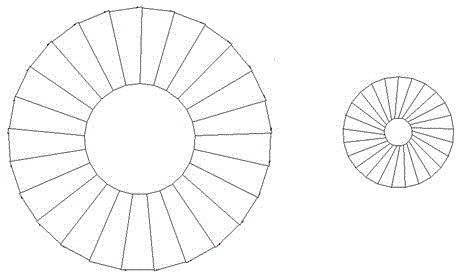

[0022] figure 2 It is a schematic diagram of the adjustable nozzle mechanism. When a larger are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com