Ejector capable of automatically regulating area ratio along with condensing temperature and jet type refrigerating machine

A technology of automatic adjustment and condensation temperature, applied in refrigerators, machines using refrigerant evaporation, refrigeration components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

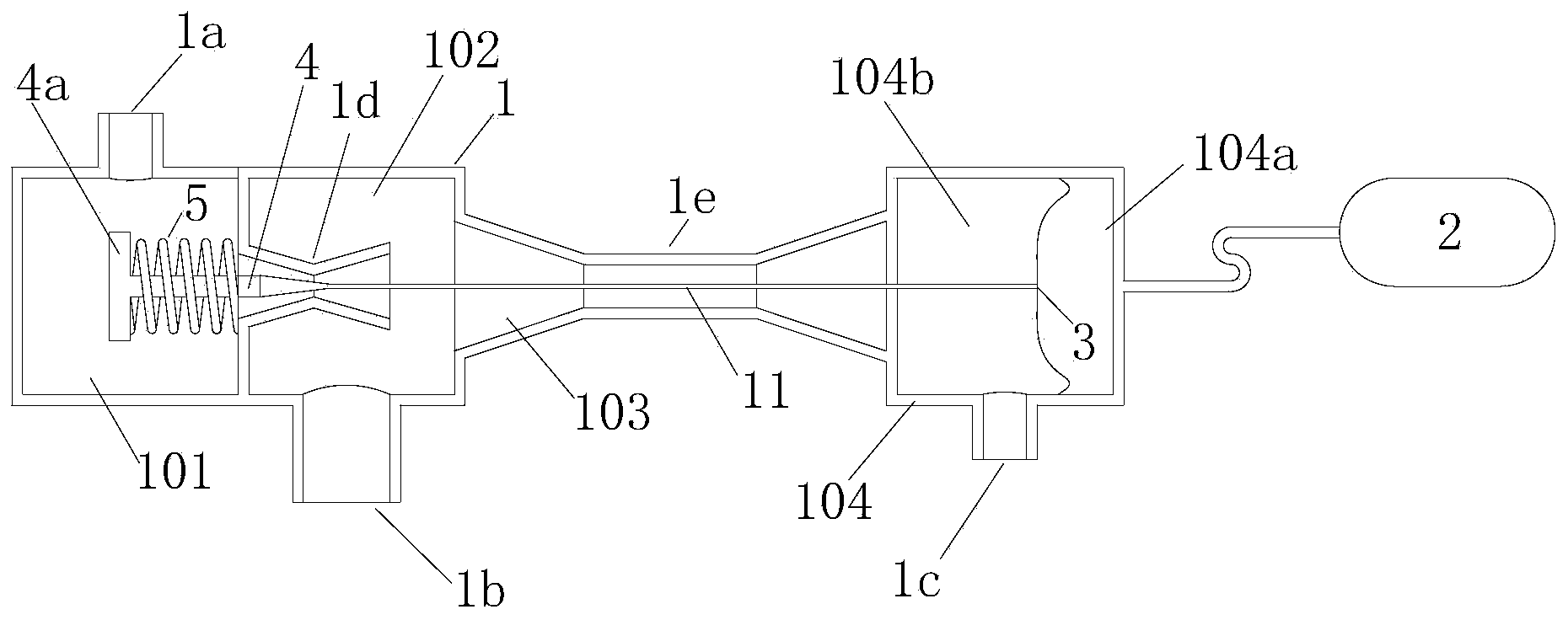

[0036] like figure 1 As shown, an injector that automatically adjusts the area ratio with the condensing temperature includes an injector cavity 1 including a working fluid inlet 1a, an injection fluid inlet 1b, a fluid outlet 1c, a working fluid nozzle 1d, and a diffuser chamber 1e, and The injector cavity 1 is connected to the temperature sensing package 2, the injector cavity 1 is divided into two spaces respectively connected with the temperature sensing package 2 and the fluid outlet 1c, the diaphragm 3, the adjusting cone 4, and the spring 5;

[0037] The injection cavity 1 is divided into a steam chamber 101, an injection chamber 102, a mixing chamber 103 and a diffusion chamber 1e. The outlet of the diffusion chamber 1e is provided with a mediation chamber 104, and the fluid outlet 1c is arranged on the side wall of the mediation chamber 104; the diaphragm 3 Set in the mediation room 104, divide the mediation room 104 into two independent spaces, the active room 104a a...

Embodiment 2

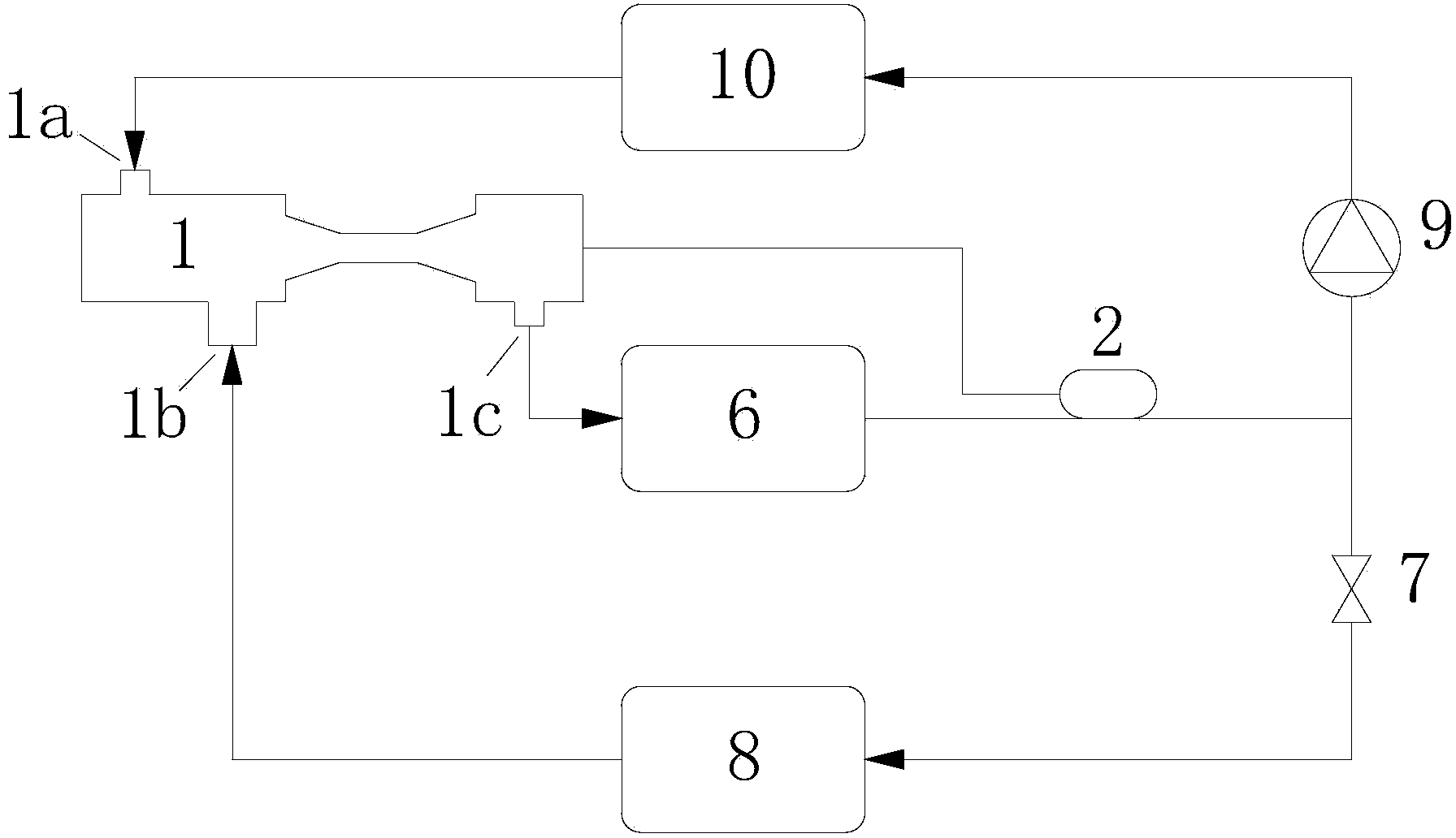

[0043] This embodiment is a specific application carried out on the basis of Embodiment 1, a kind of ejector refrigerator using the ejector of Embodiment 1, such as figure 2 shown in figure 1 On the basis of the system shown, it also includes a condenser 6, a throttle valve 7, an evaporator 8, a circulation pump 9, and a generator 10; the fluid outlet 1c is connected to the inlet of the condenser 6, and the outlet of the condenser 6 is connected to the inlet of the circulation pump 9 , the inlet of the throttle valve 7 is connected at the same time, the outlet of the circulation pump 9 is connected with the inlet of the generator 10, the outlet of the generator 10 is connected with the inlet 1a of the working fluid, the outlet of the throttle valve 7 is connected with the inlet of the evaporator 8, and the outlet of the evaporator 8 Connected with ejection fluid inlet 1b;

[0044] The temperature sensing package 2 is located on the pipeline connecting the outlet of the conde...

Embodiment 3

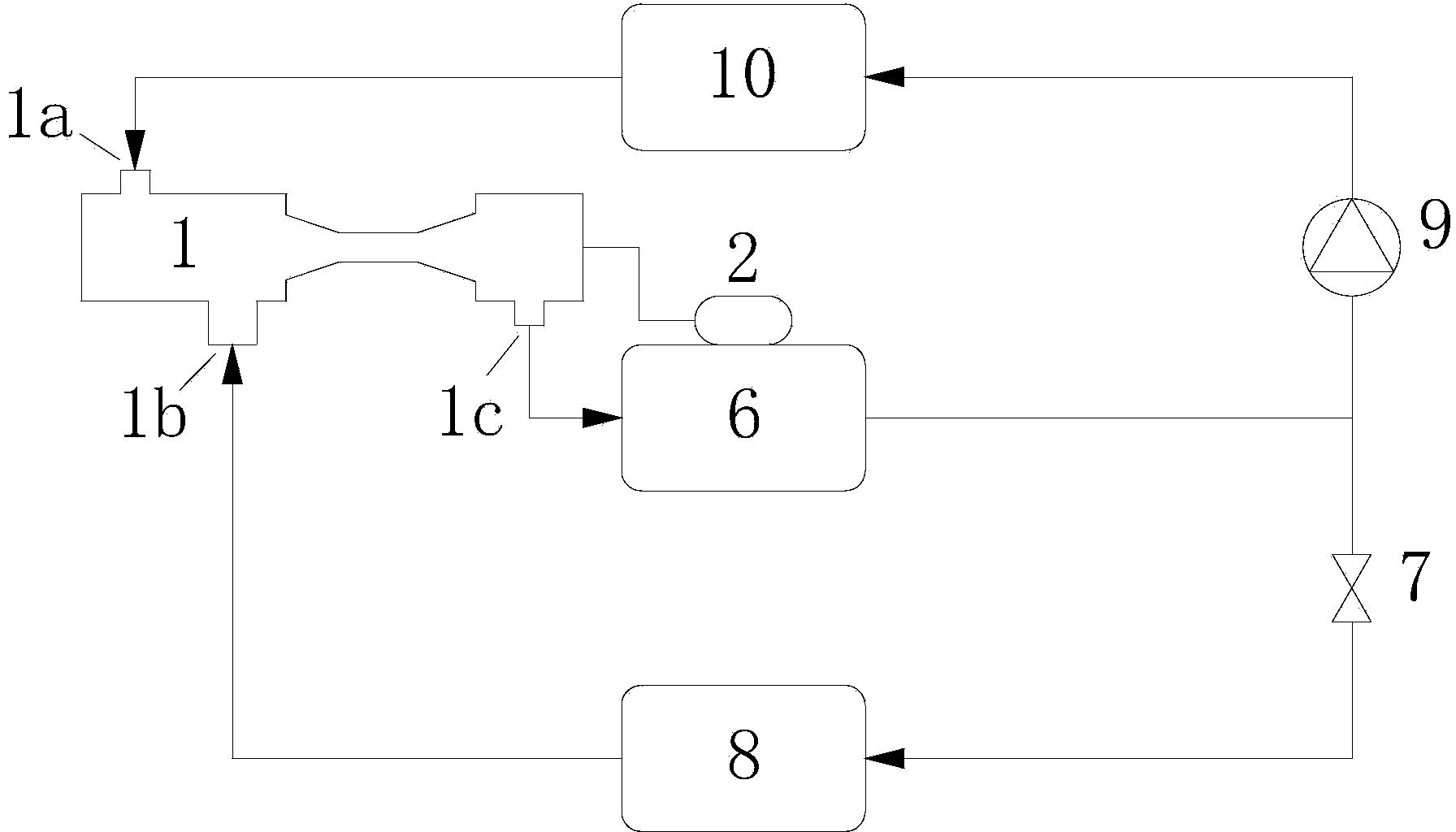

[0049] like image 3 As shown, this embodiment is an improvement on the basis of Example 2. The temperature sensing package 2 is located on the wall of the condenser 6. The heat exchange between the working fluids makes the pressure change in the temperature sensing bulb 2 more sensitive to the change of the condensation temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com