Gearshift rocker arm component of bi-gear gearbox assembly of electric vehicle

A technology for shifting rocker arms and electric vehicles, which is applied to components with teeth, transmission control, belts/chains/gears, etc. It can solve the problems of inability to shift gears, output torque and speed that cannot be adjusted according to road conditions, and road conditions. Poor ability and other problems, to achieve the effect of reliable installation, easy implementation, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

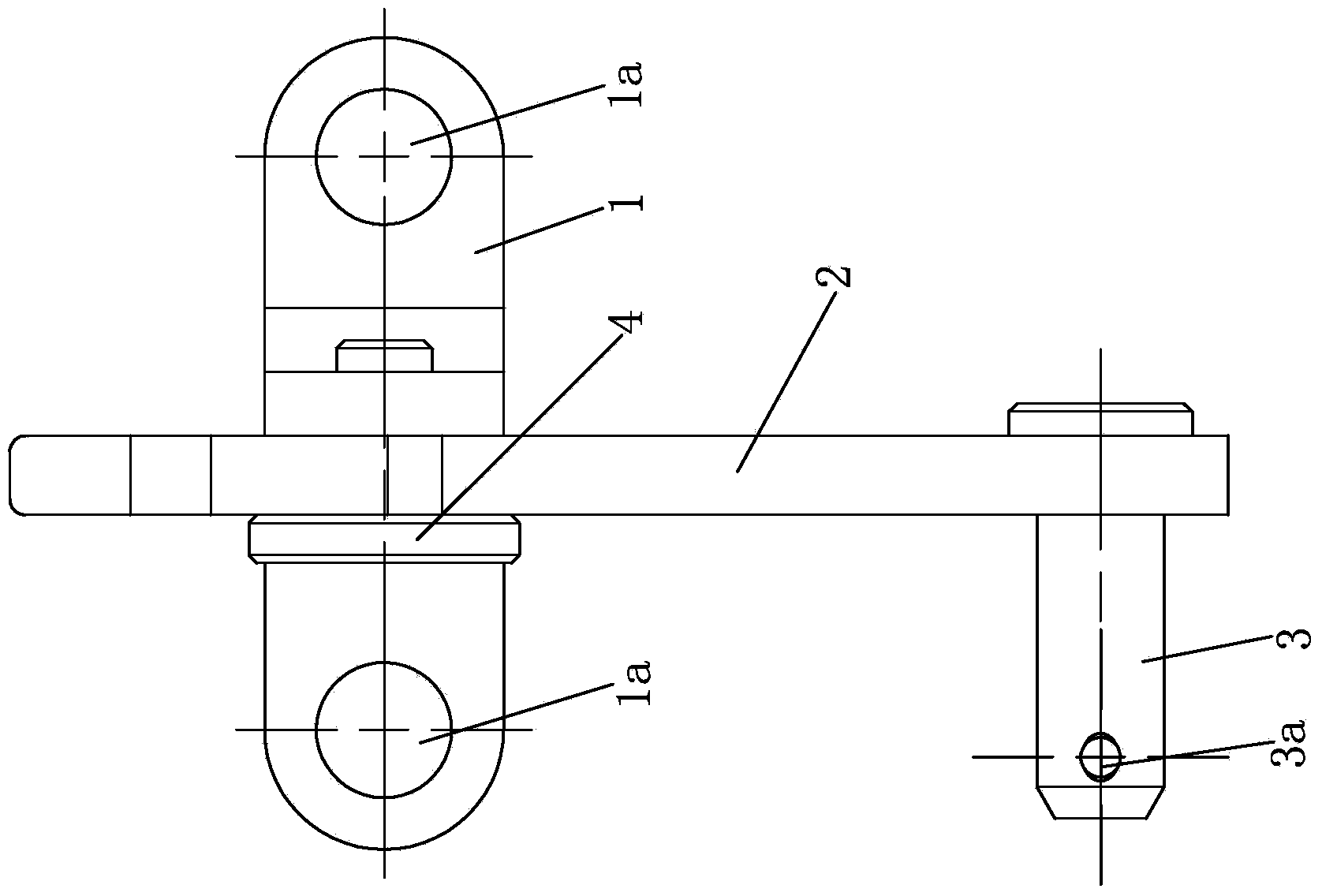

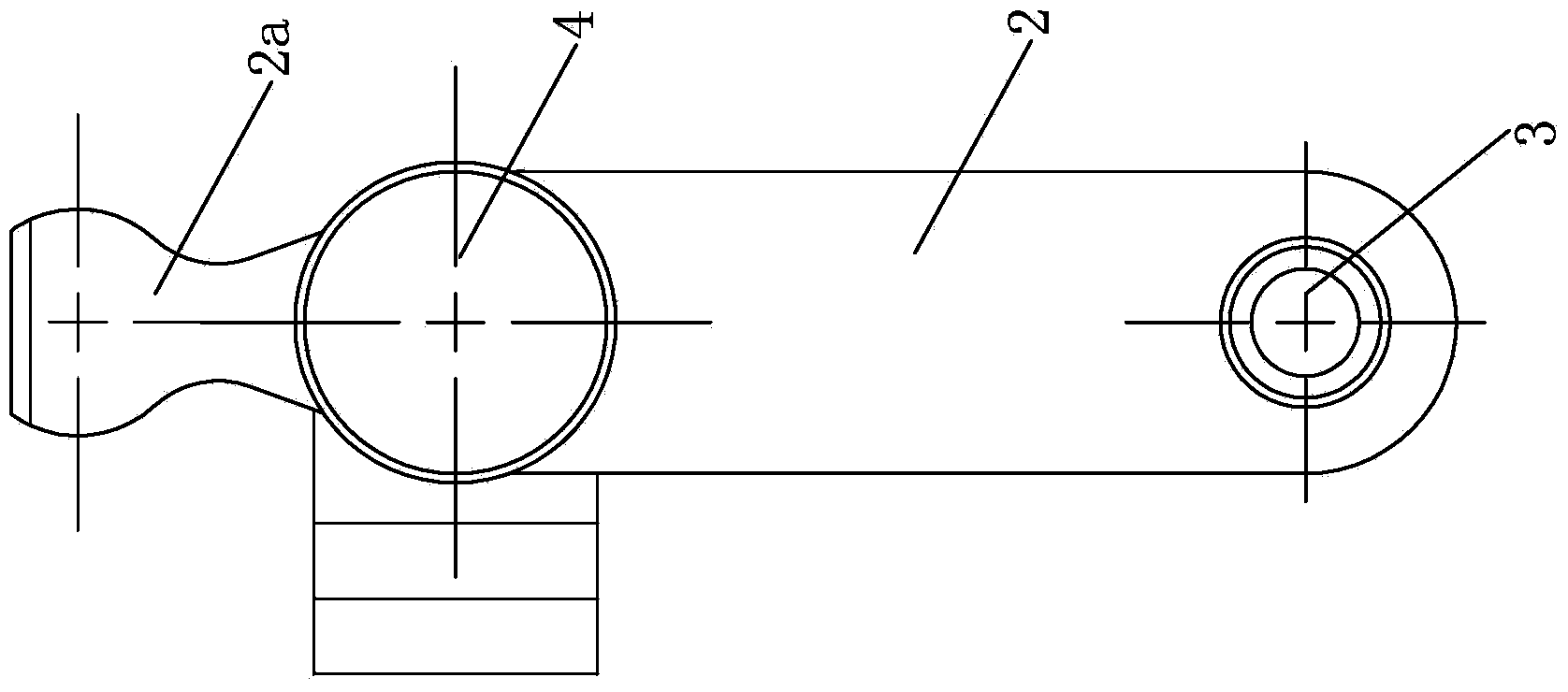

[0013] Such as figure 1 , 2 As shown, a shift rocker assembly of a second-speed electric vehicle transmission assembly is composed of a shift rocker base 1, a rocker 2, a cable pin 3 and a rocker pin 4, and these four parts are all steel parts . Wherein, the shift rocker seat 1 is a "T" shape structure, and the two ends of the short arm section of the shift rocker seat 1 are respectively provided with a mounting hole 1a, and the mounting hole 1a is about the long arm of the shift rocker seat 1. Segment symmetry set.

[0014] The rocker arm 2 is a sheet structure, and a cable pin 3 is welded vertically at the lower end of the rocker arm 2. The left end of the cable pin 3 is a free end, and a cotter pin mounting hole 3a is formed at the free end. The cotter pin mounting hole has a diameter of 2.5mm and a tolerance of 2 wires. In this case, the cable pin 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com