Axial magnetic bearing static characteristic testing device

A technology of magnetic suspension bearing and static characteristics, applied in the direction of mechanical bearing testing, etc., can solve the problems of decreased test accuracy, no displacement detection element, complicated disassembly and assembly, etc., to achieve good quality and performance, simple test process, and improved test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

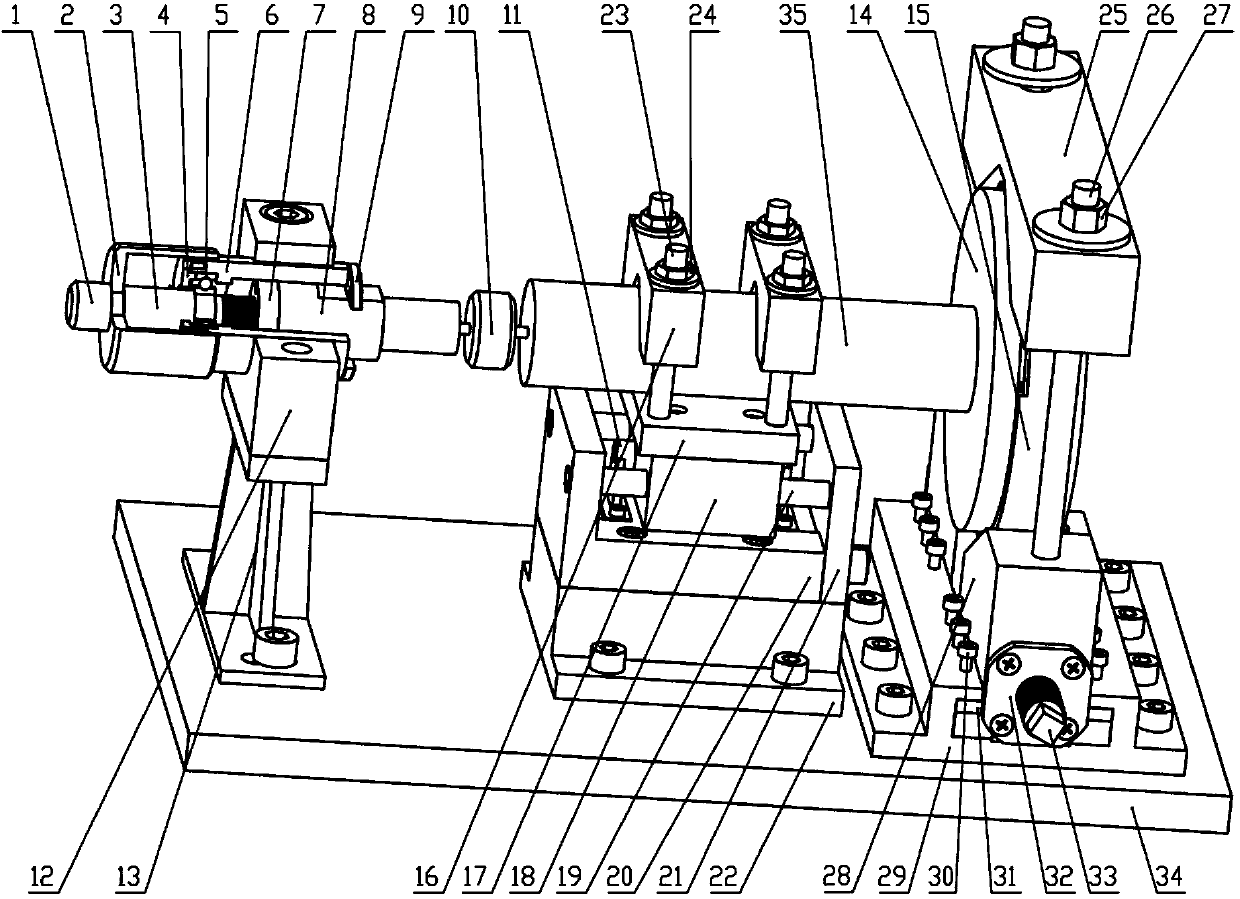

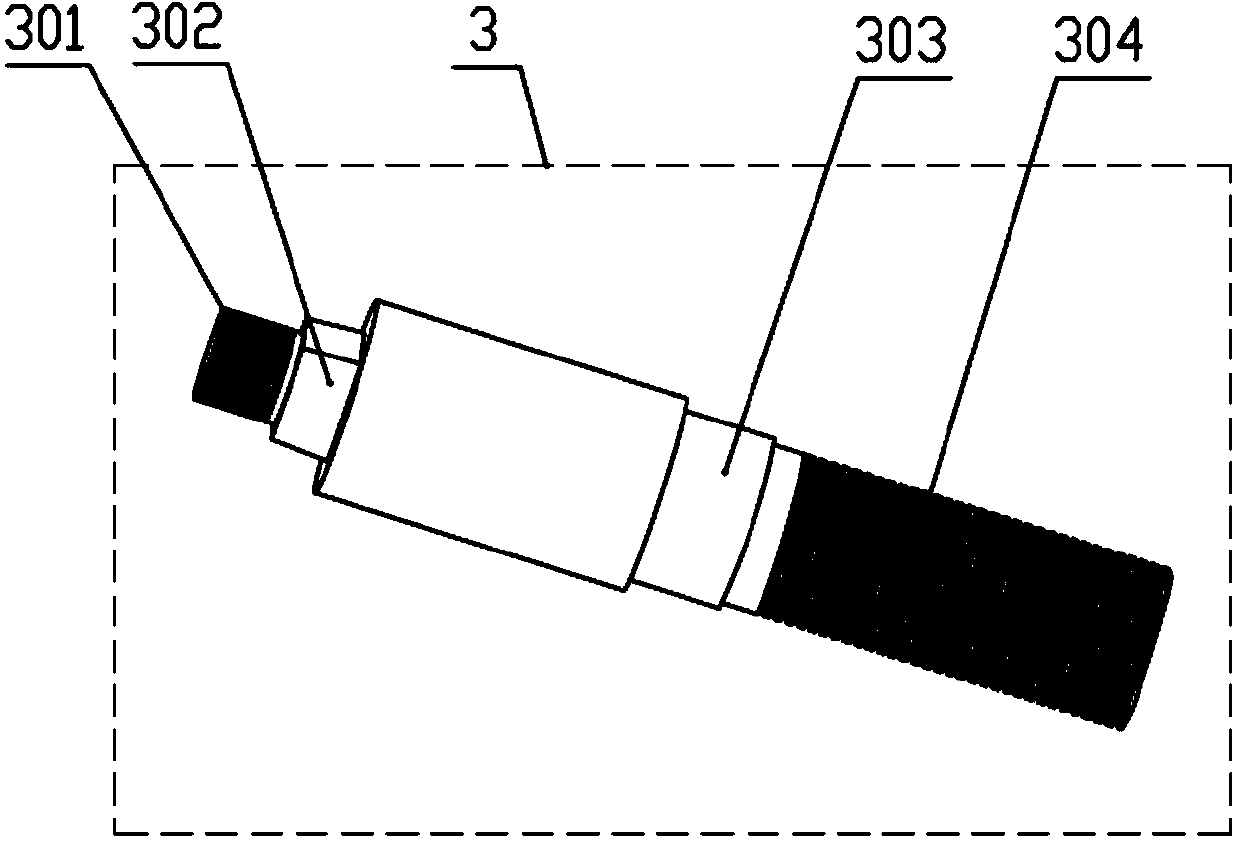

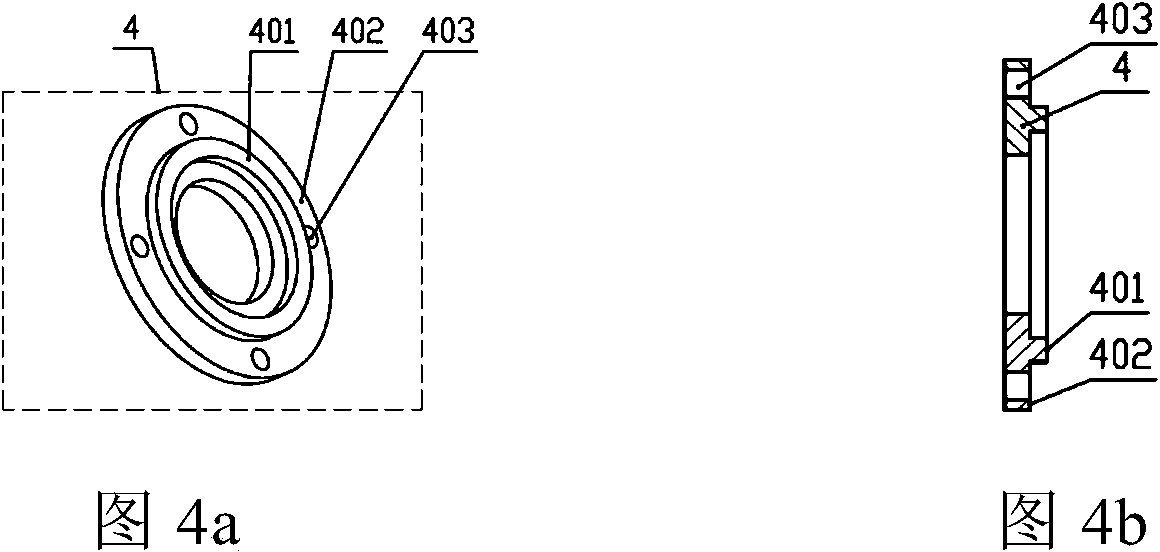

[0024] Such as figure 1 As shown, the present invention is mainly composed of a loading and measuring system, an axial magnetic suspension bearing to be tested, a rotor axial sliding mechanism, a stator fixing and a height adjustment system, wherein the loading and measuring system includes: a lock nut 1, a loading rotating cover 2 , Loading screw 3, Sleeve end cover 4, Deep groove ball bearing 5, Sleeve 6, Small nut 7, Moving rod 8, Thrust plate 9, Dynamometer 10, Displacement sensor 11, Loading fixture 12, Loading base 13. The tested axial magnetic suspension bearing includes: rotor 14, stator 15; the rotor axial sliding mechanism includes: upper pressure block 16, transition plate 17, slider 18, slide rail 19, slide rail base 20, end plate 21, slide Rail mounting base 22, upper pressing block pressing rod 23, upper pressing block pressing nut 24, rotor axial pushing rod 35; stator fixing and height adjustment system includes: upper V-shaped block 25, pressing bar 26, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com