Electromagnetic type power master switch for car

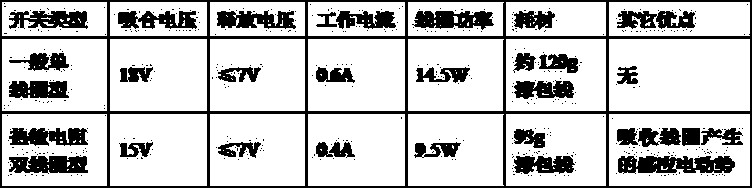

A master switch and electromagnetic technology, applied in electromagnetic relays, electromagnetic relay details, circuits, etc., can solve problems such as power loss and waste of power, and achieve the effects of reducing consumables, energy consumption, and pull-in voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

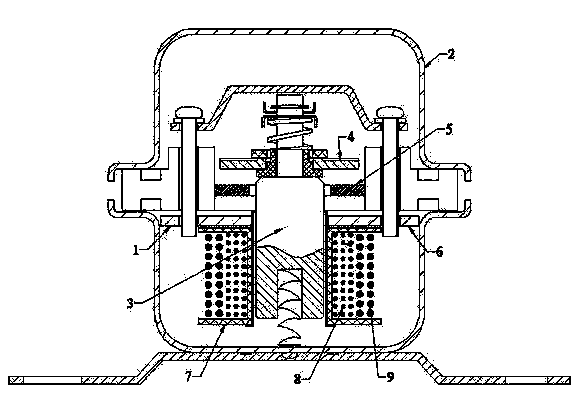

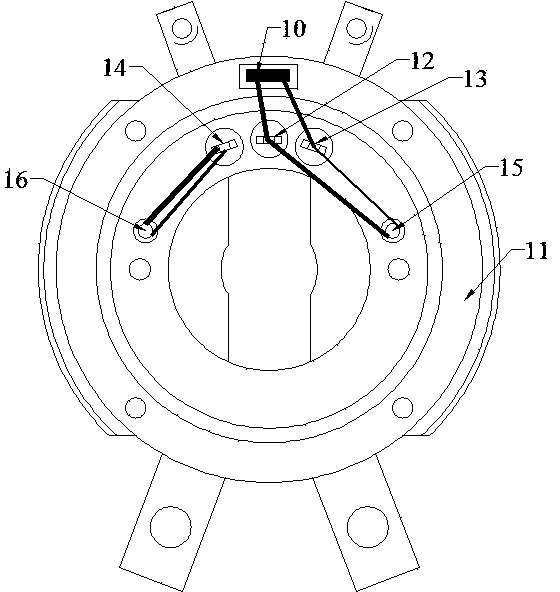

[0009] Embodiments are described in detail with reference to the accompanying drawings. An electromagnetic type power switch for a vehicle, comprising an electromagnetic component 1, a metal shell 2, a moving iron core 3, a moving contact piece component 4 and a fixed electrode 5, the electromagnetic component 1 is mainly composed of a magnetically conductive plate 6, a wire frame 7 and the main coil 8 and auxiliary coil 9 arranged on the wire frame 7, wherein the auxiliary coil 9 is arranged outside the main coil 8, and a thermistor 10 is connected in series on the closed circuit of the auxiliary coil 9, the thermistor 10 is fixed in the groove of Bakelite 11 by 906 insulating glue, and one end of the thermistor 10 is connected to the first terminal 12 with the outlet end of the auxiliary coil 9 drawn out from the coil inlet hole 15, and the thermistor 10 The other end of the coil is connected to the second terminal 13 with the inlet end of the main coil 8 drawn out from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com