Heat conduction and radiation device

A technology of heat dissipation device and heat conduction copper pipe, which is applied in the direction of cooling/ventilation/heating transformation, etc., which can solve the problems of component damage, economic loss of enterprises or users, small size, etc., and achieve enhanced heat conduction and heat dissipation performance, wide application range, and reduced temperature difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

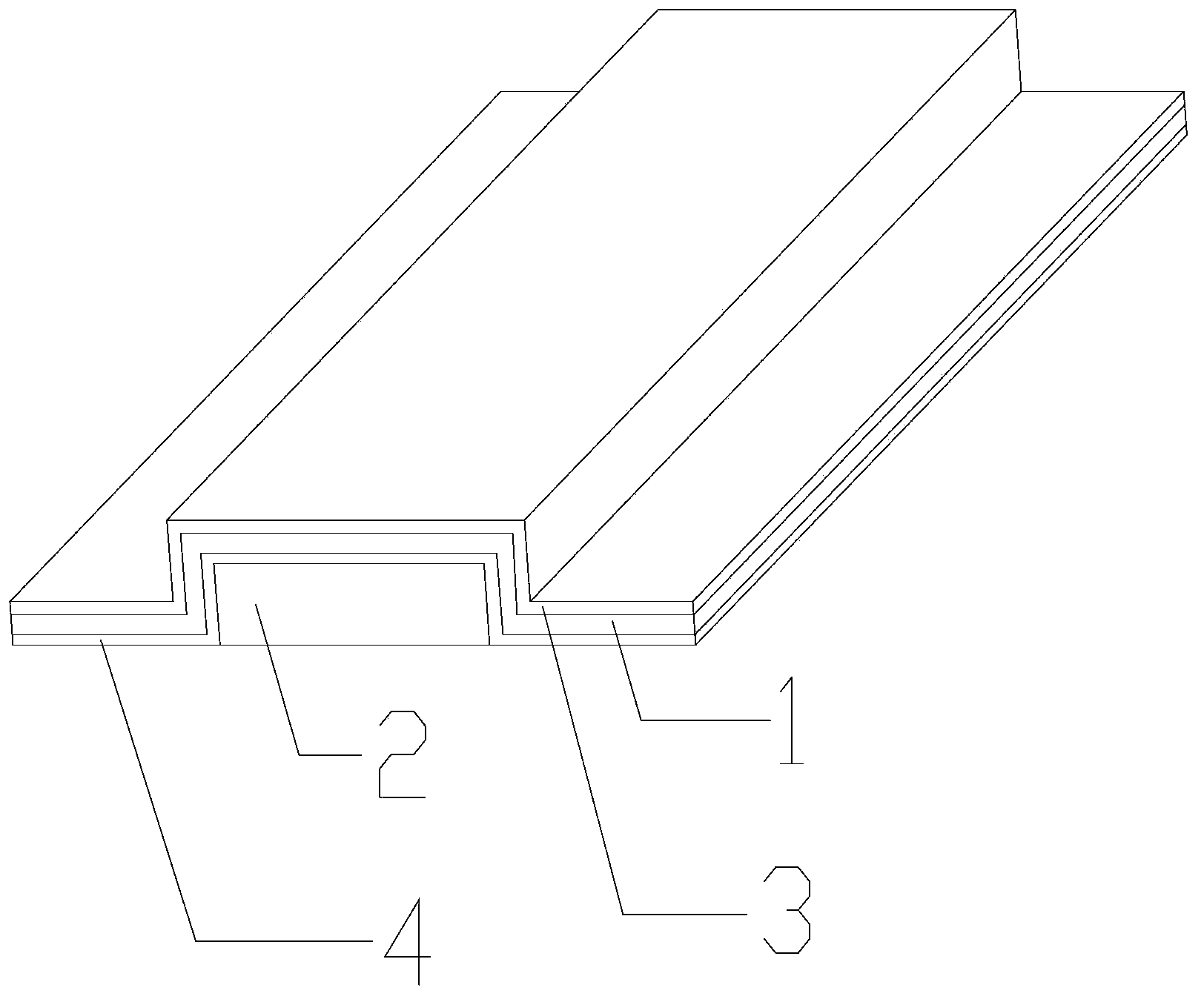

[0016] A heat conduction and heat dissipation device provided by the present invention, such as figure 1 As shown, it includes artificial graphite sheet 1, heat-conducting copper tube 2 and film 3. Artificial graphite sheet 1 is a sheet structure, and heat-conducting copper tube 2 is a flat structure. One side of artificial graphite sheet 1 is pasted with film 3, and the other side is bonded to film 3. One side and two sides of the heat-conducting copper tube 2 are pasted together, and the artificial graphite sheet 1 and the heat-conducting copper tube 2 are pasted together by double-sided adhesive tape 4 .

[0017] During use, since the width of the artificial graphite sheet 1 is greater than that of the heat-conducting copper tube 2, one side of the artificial graphite sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com