Special-medicine fragmentation sorting machine group

A crusher and unit technology, applied in the direction of solid separation, filter screen, grille, etc., can solve problems affecting product quality, etc., and achieve the effects of easy industrial manufacturing, convenient disassembly and assembly, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

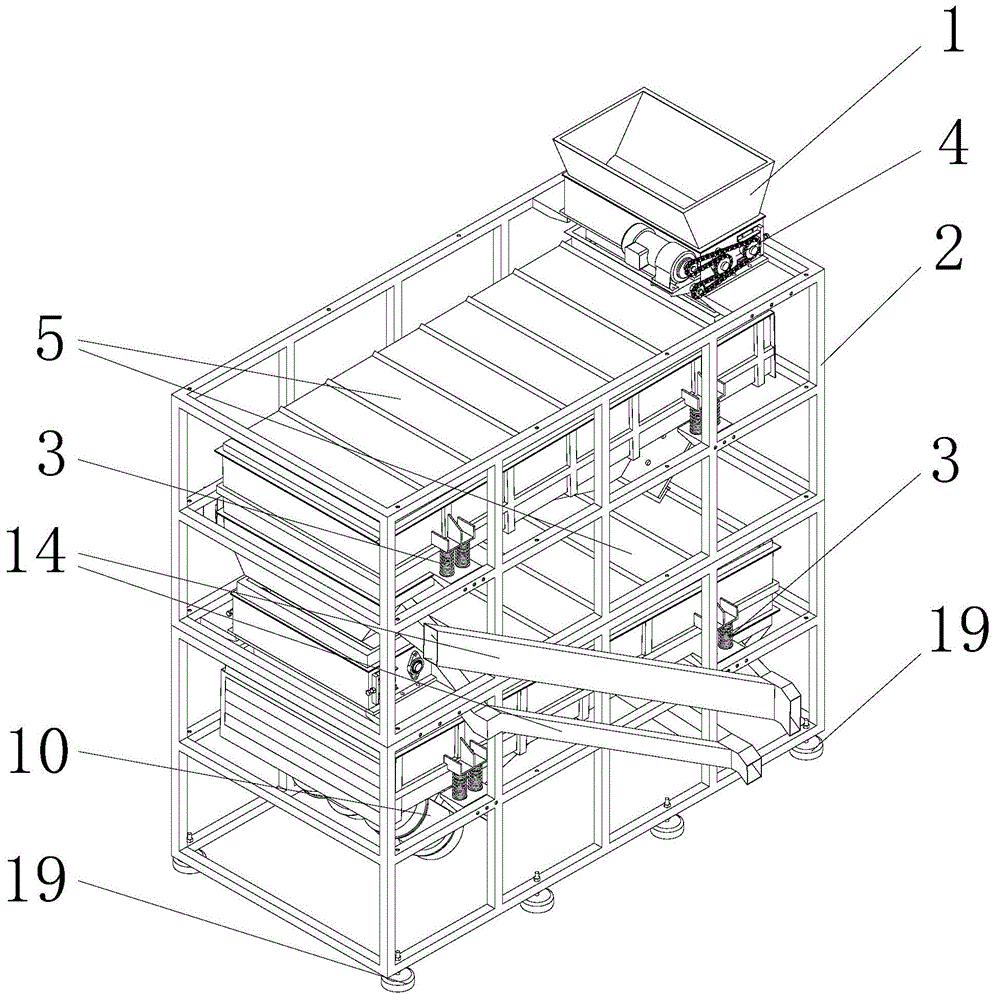

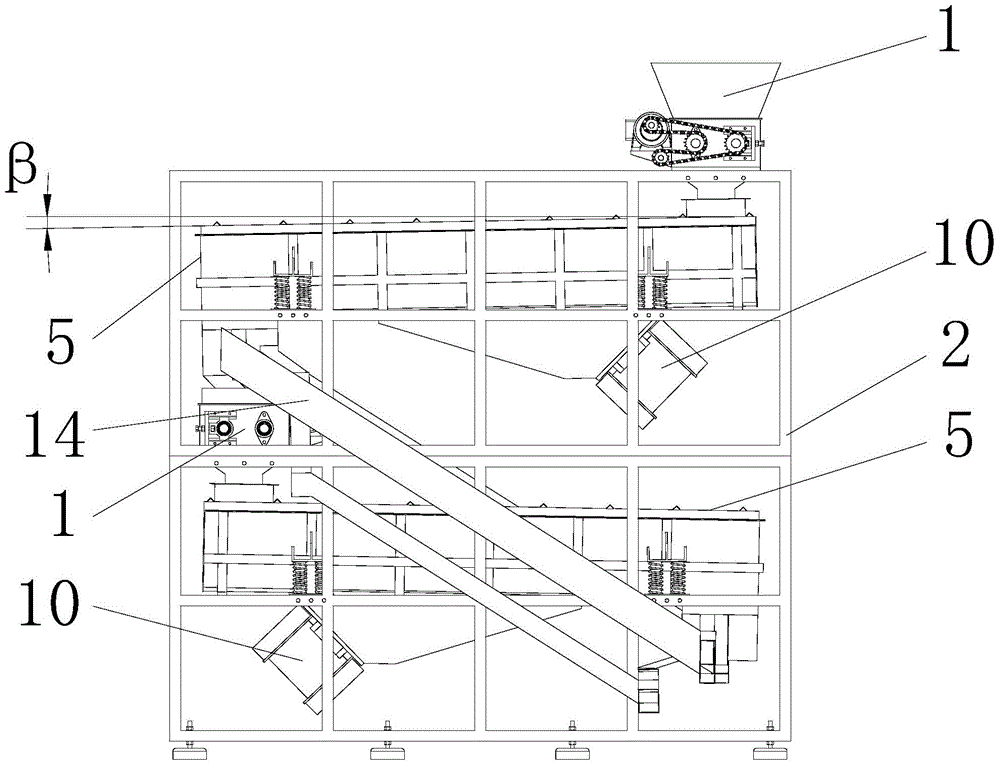

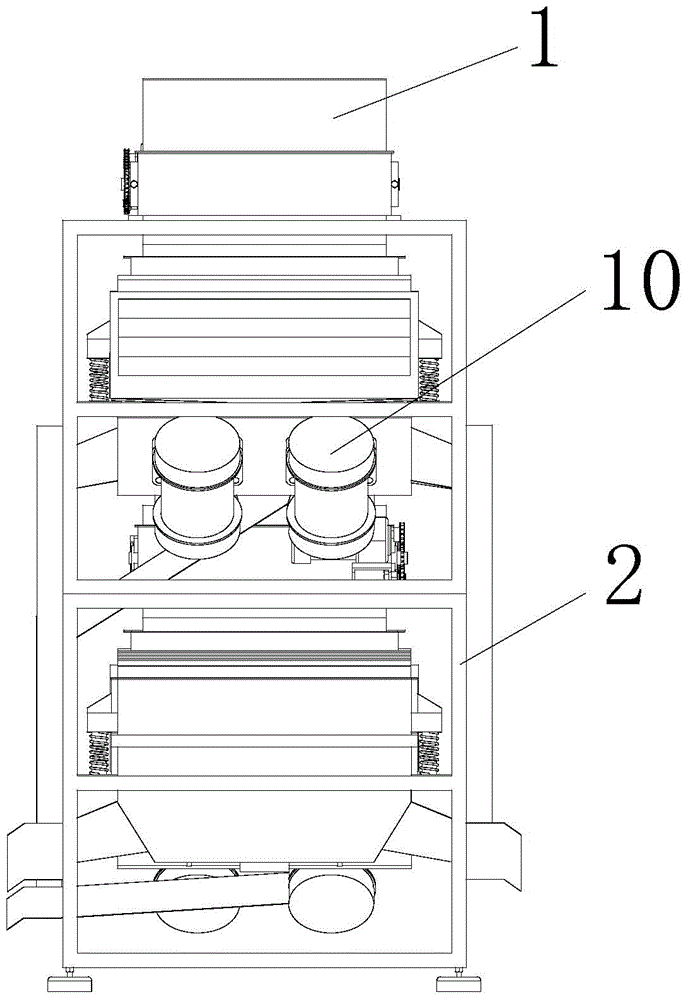

[0038] A crushing and sorting unit for special medicines, including a feed hopper 1, a frame 2, a spring 3 and a crushing and screening unit, the crushing and screening unit includes a crusher 4 and a screening machine 5, the discharge port of the crusher 4 and the screening machine 5 The inlet is connected, and the screening machine 5 is obliquely connected to the frame 1 by a spring 3. Specifically, the inlet of the screening machine 5 is inclined downward toward the outlet, and the inclination angle β is 5-15°, preferably Yes, the inclination angle β is 5-10°, that is, the position of the inlet of the screening machine 5 is higher than the position of the outlet, and the screening machine 5 includes a screening box 6, a primary filter screen 7, and a shell screen 8 And the grain screen 9, the primary filter screen 7, the shell screen 8 and the grain screen 9 are successively arranged in the screening box 6 from top to bottom, and the screen hole of the primary filter 7 is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com