Oiling device for rubber pipe water tank drawing machine

A technology of a water tank wire drawing machine and an oiling device, which is applied in the direction of a device for coating liquid on the surface, a coating, etc., can solve the problems of reducing the adhesion between the steel wire and the rubber, no anti-rust facilities, and the steel wire is easy to rust, etc. The effect of prolonging storage time and delaying rust time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

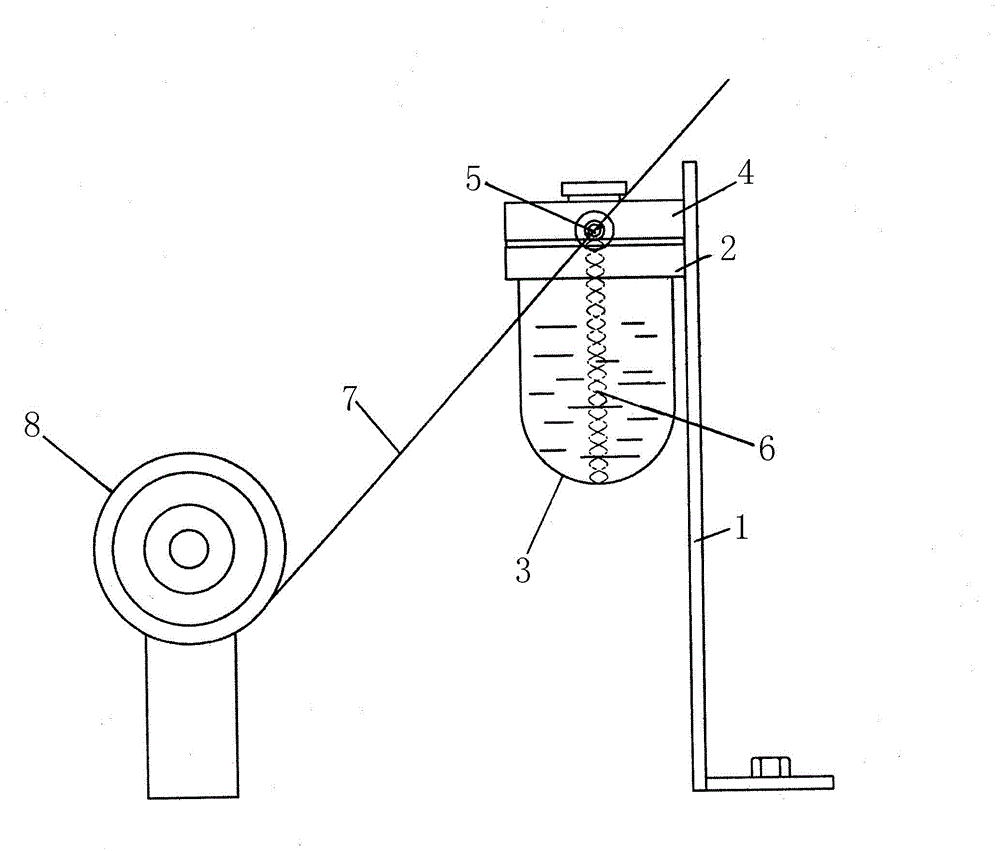

[0009] Such as figure 1 As shown, the present invention fixes organic glass bottle 3 by fixing device 2 on the top side of support 1, is covered with bottle cap 4 on the upper opening of described organic glass bottle 3, and aperture 5 is located at the bottom of described bottle cap 4 On one side, the cotton core 6 is arranged in the inside of the machine glass bottle 3, and one end of the cotton core 6 passes through the aperture 5 on the bottle cap 4. Through the above settings, anti-rust oil is packed into the organic glass bottle 3 of the present invention, and the bottle cap 4 is covered. The anti-rust oil penetrates to the top of the cotton core 6 from the inside of the organic glass bottle 3 through the cotton core 6, and the steel wire 7 is pulled from the water tank. After drawing and molding, pass through the cotton core 6 on the side of the bottle cap 4 on the plexiglass bottle 3, and then take up the wire through the I-shaped wheel 8. The antirust oil on the cotto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com