Diamond processing method

A processing method and diamond technology, applied in the field of diamond processing, can solve problems such as the bow tie effect, achieve the effect of increasing weight and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

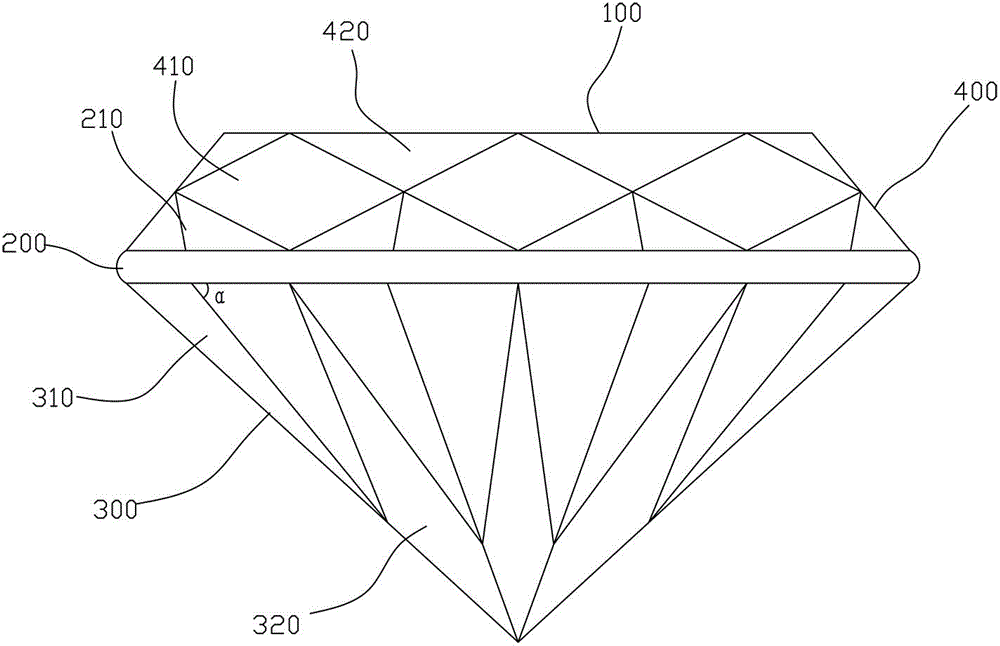

[0037] Example 1 (round diamond)

[0038] A diamond processing method, comprising the steps of,

[0039] (1), desktop cutting, cutting out the desktop 10 on the diamond blank 101 (see figure 2 );

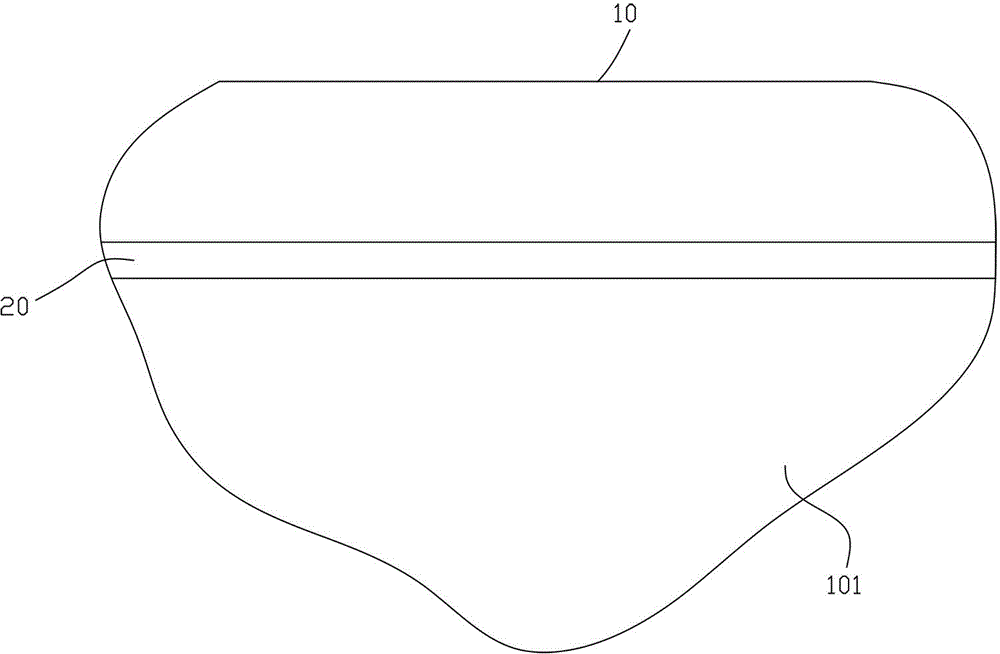

[0040](2), the waist is formed, and the waist 20 is polished on the rough diamond 101 (see image 3 );

[0041] (3) Bottom processing, on the diamond blank, the part below the waist 20 is processed into an approximately conical bottom (30); specifically, based on the datum plane 31 of the waist 20, the first included angle α is 45 degrees- At 48 degrees, the part next to the waist 20 is ground into 8 equal bottom surfaces 32, and the height h1 corresponding to the bottom surface 32 accounts for 20%-40% of the height h from the reference plane 31 of the waist 20 to the top 33 of the bottom 30 ( See Figure 4 and Figure 5 );

[0042] (4), on the basis of the 8 bottom surfaces 32, select 4 mutually symmetrical bottom surfaces 32 and polish the pick-up surface 34 with the s...

Embodiment 2

[0048] A diamond processing method, comprising the steps of,

[0049] (1) Cutting the desktop, cutting out the desktop on the rough diamond;

[0050] (2) The waist is formed, and the waist is polished on the rough diamond;

[0051] (3) Bottom processing, on the diamond blank, the part below the waist is processed into an approximately conical bottom; specifically, for oval ( Figure 9 ) or marquise ( Figure 10 ) diamond, with the datum plane of the girdle as the reference, the part next to the girdle is polished into 6 bottom surfaces at a first included angle, wherein the first included angle adopted by the first bottom surface 51 and the second bottom surface 52 is 40°-42°; the angle of the first included angle adopted from the third bottom surface to the sixth bottom surface 53, 54, 55, 56 is 37°-39°; the height h1 corresponding to the bottom surface occupies the reference plane from the waist to the bottom 70%-80% of the height h of the top; on the basis of the 6 botto...

Embodiment 3

[0053] A diamond processing method, comprising the steps of,

[0054] (1) Cutting the desktop, cutting out the desktop on the rough diamond;

[0055] (2) The waist is formed, and the waist is polished on the rough diamond;

[0056] (3) Bottom processing, on the diamond blank, the part below the waist is processed into an approximately conical bottom; specifically, for the pear shape ( Figure 11 ) diamonds, with the datum plane of the girdle as the reference, the part immediately adjacent to the girdle is polished into 7 bases at the first included angle, among which, the first base to the fifth base 61, 62, 63, 64, 65 The first included angle adopted is 40°-42°; the first included angle adopted by the sixth and seventh bottom surfaces 66, 67 is 37°-39°; the height corresponding to the bottom surface occupies the reference plane of the waist to the bottom 70%-80% of the height of the top of the top; on the basis of the 7 bottom surfaces, the sharpened surface is polished at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com