Fully-mechanized semi-automatic carton stitching machine

A semi-automatic, fully mechanical technology, applied in container manufacturing machinery, papermaking, paper/cardboard containers, etc., can solve the problems of poor control stability, dependence on software programs, high failure rate, and achieve high reliability, smooth control operation, and failure rate. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

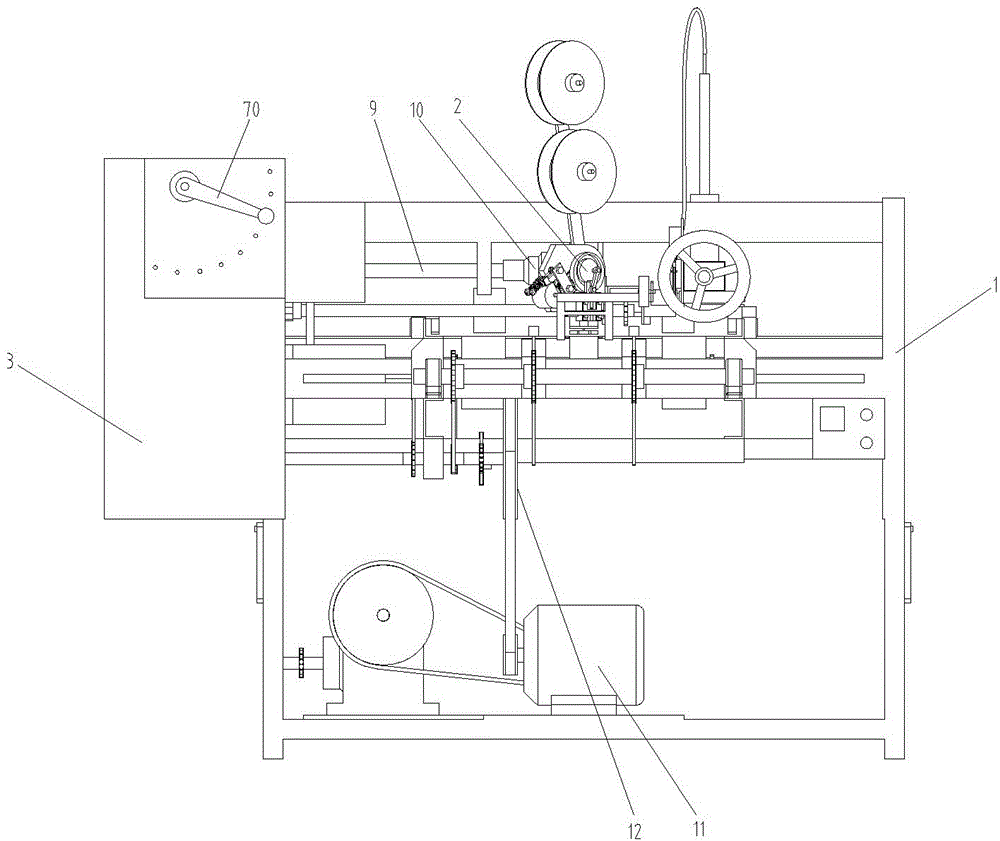

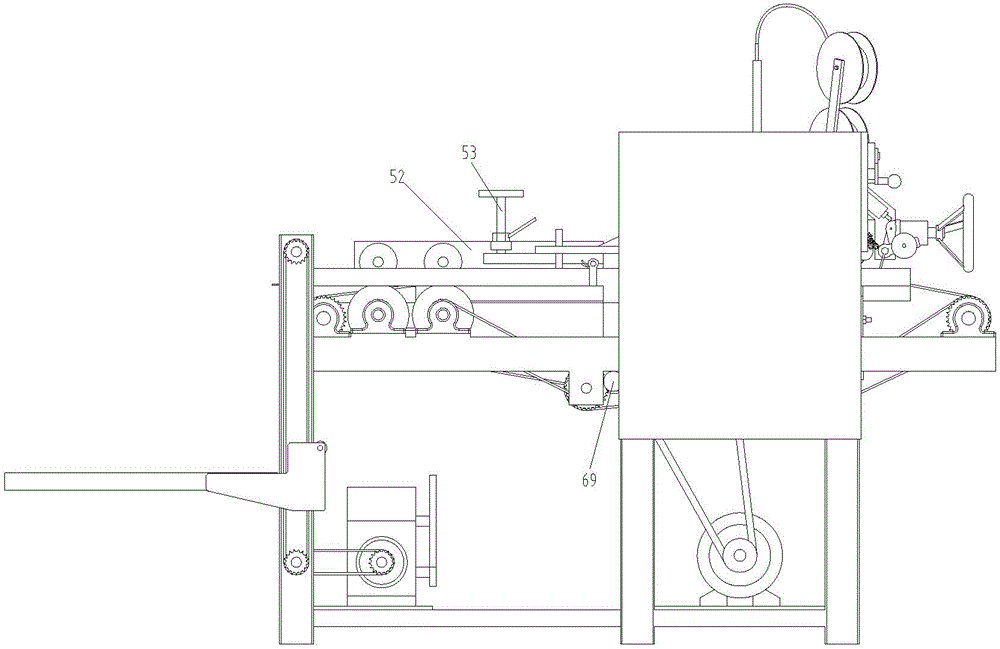

[0029] like Figure 1-9 As shown, a fully mechanical semi-automatic carton nailing machine is characterized in that it includes a frame 1, a binding head 2, a binding head driving part, a carton board driving part and a feeding lifting platform part.

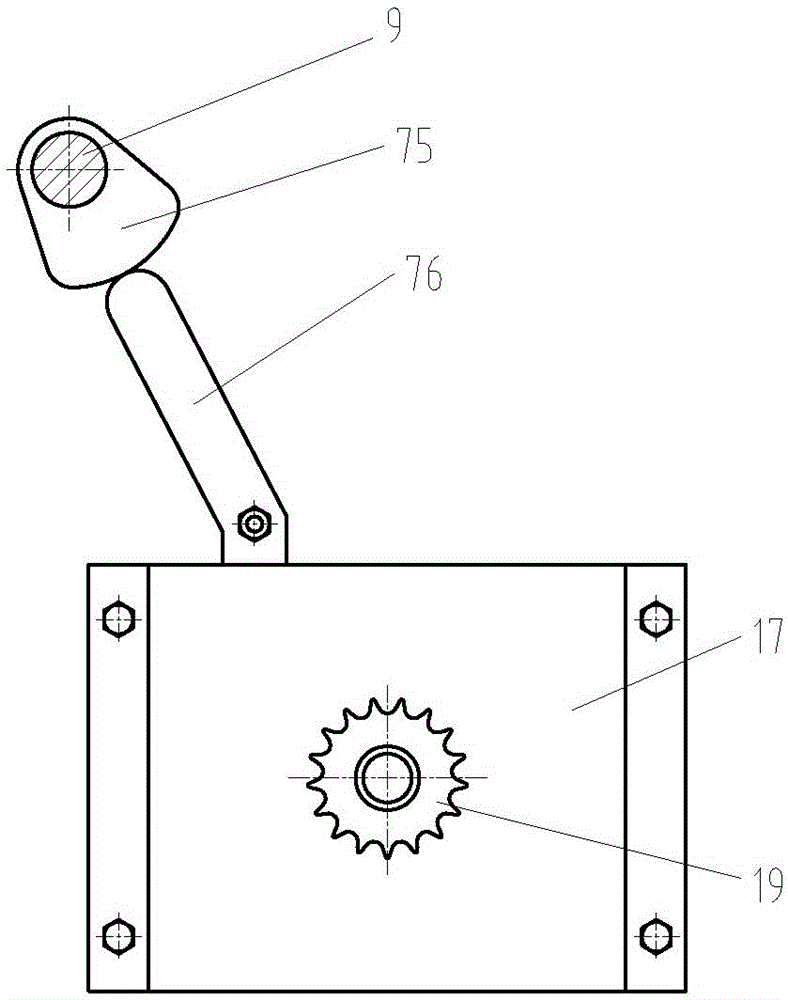

[0030] The binding head 2 is obliquely installed in the middle of the front end of the frame 1. The binding head driving part is arranged in the control box 3 on the left side of the front end of the frame 1. The binding head driving part is provided with a driving motor 4, which is driven by the driving motor 4 through a belt. The pulley 5 and the pulley shaft 6 rotate, the pulley shaft 6 is connected to the main shaft 9 through a clutch 7, the clutch 7 is controlled by an electromagnet 51, and is controlled by a mechanical counter 8 at the same time, and the other end of the main shaft 9 passes through a differential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com