Method and tool for unloading wall panel assemblies at cargo space doors of airplanes

A cargo door, wall panel technology, applied in aircraft parts, aircraft assembly, load hanging components, etc., can solve the problems of shortening the time of taking off the shelf, non-uniform positioning benchmarks, etc., to avoid non-uniform positioning benchmarks, easy to operate, The effect of force equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

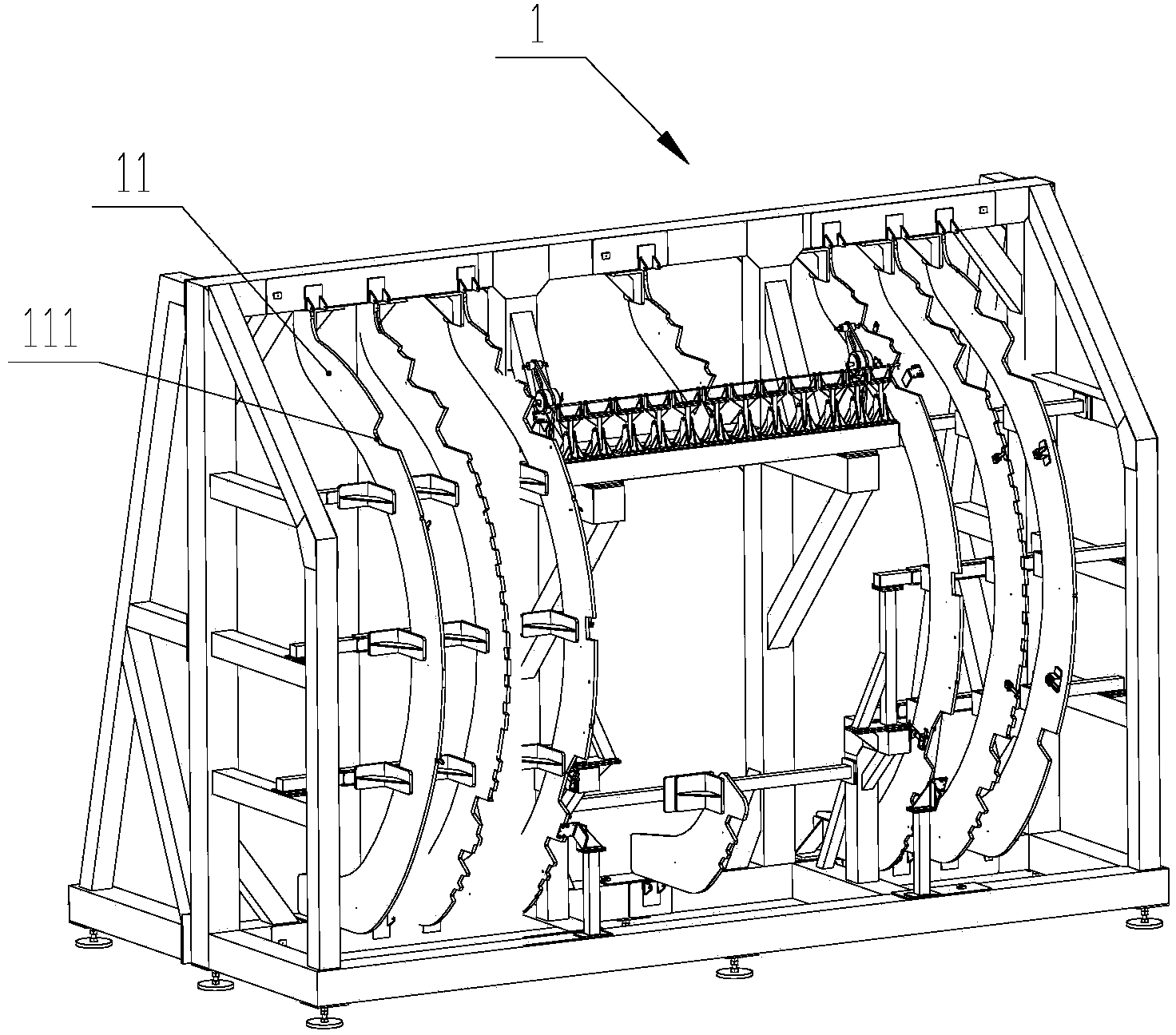

[0034] A method for removing a panel assembly at an aircraft cargo door includes the following steps:

[0035] Step 1: Assembling, assembling the panel parts after the assembly positioning and hole making into the panel assembly 2 on the assembly tool 1;

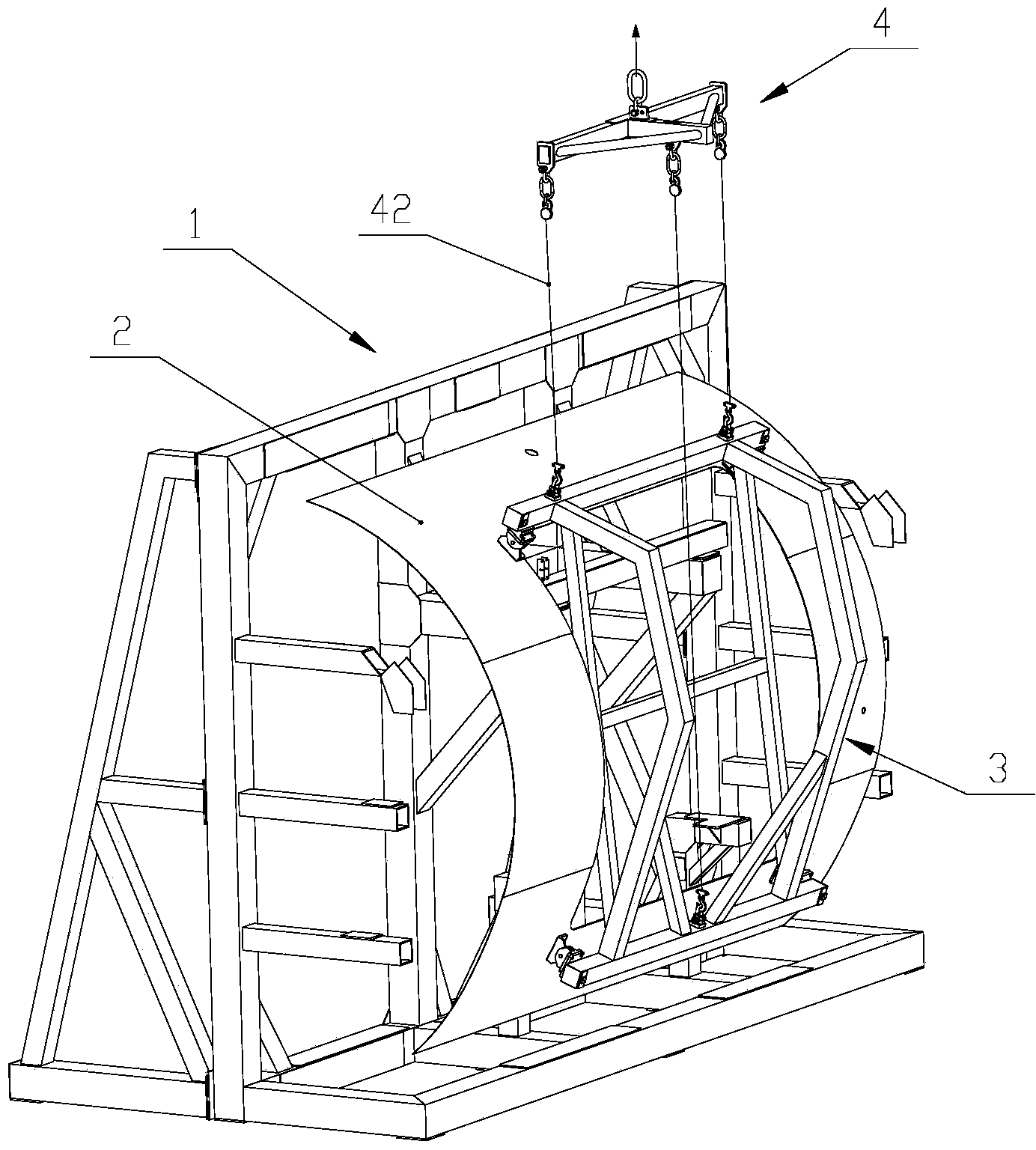

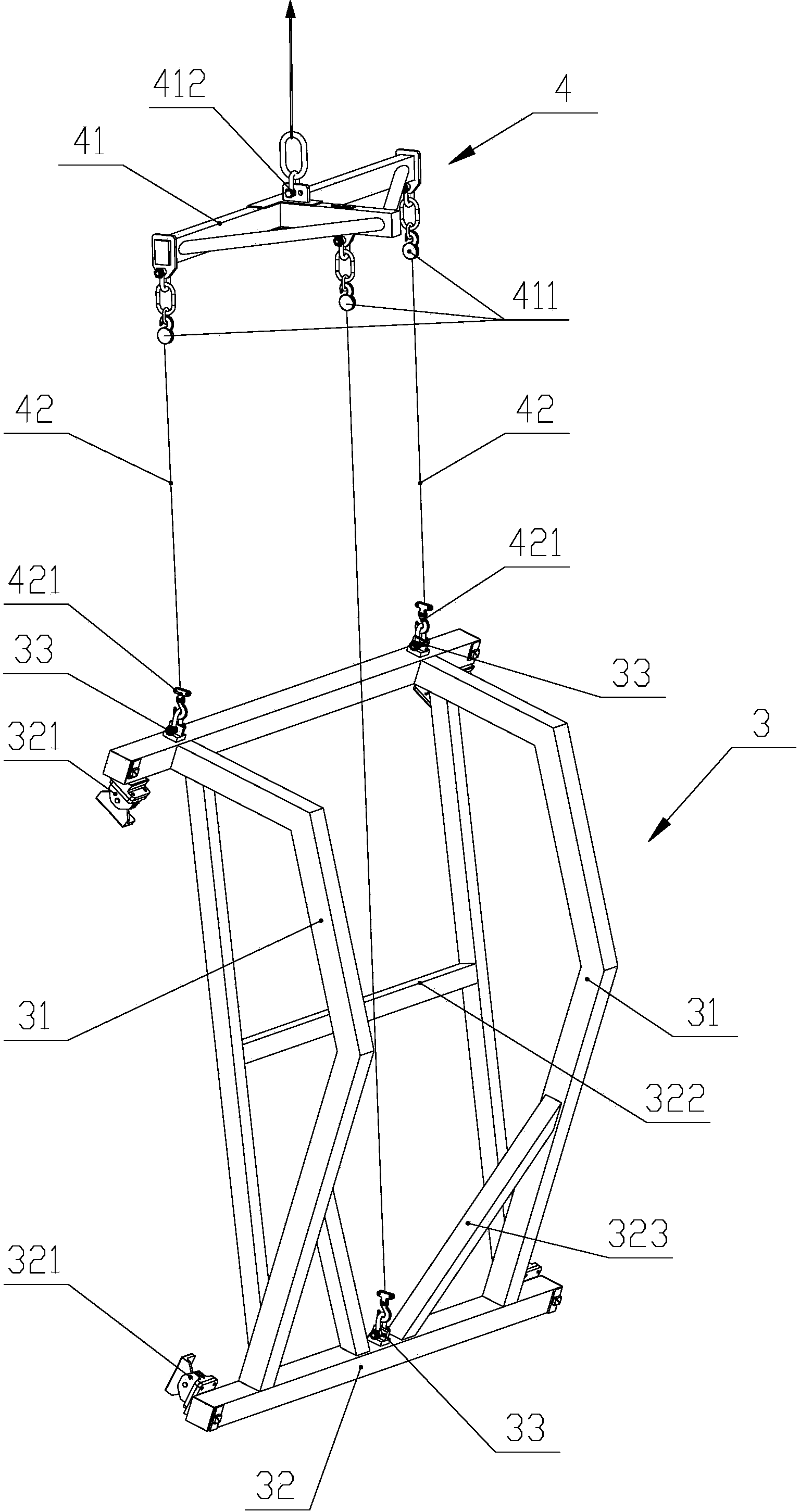

[0036] Step 2: Installing, installing and fixing the shape-preserving tool 3 on the wall panel assembly 2, and the shape-keeping tool 3 is connected and fixed to at least four different parts on the wall panel assembly 2;

[0037] Step 3: connecting, connecting the lifting tool 4 with the shape-conserving tool 3 through the sling 42;

[0038] Step 4: Take off the shelf, firstly lift the lifting tool 4 vertically to make the sling 42 in a tensioned state, then take out the positioning pins to separate the wall panel assembly 2 from the assembly tool 1, and then move the lifting tool 4 horizontally to make the lifting The shape-preserving tooling 3 connected with the tool 4 drives the panel assembly 2 to move out from the ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com