Adaptive bag length cutting and starving and pinching detecting method for deoxidizers

A deoxidizer bag and detection method technology, applied in the direction of automatic packaging control, multiple packages, packaging, etc., can solve the problems of material belt pollution, undetectable, unusable, etc., achieve high reliability, improve production pass rate, The effect of simplifying the mechanical mounting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings.

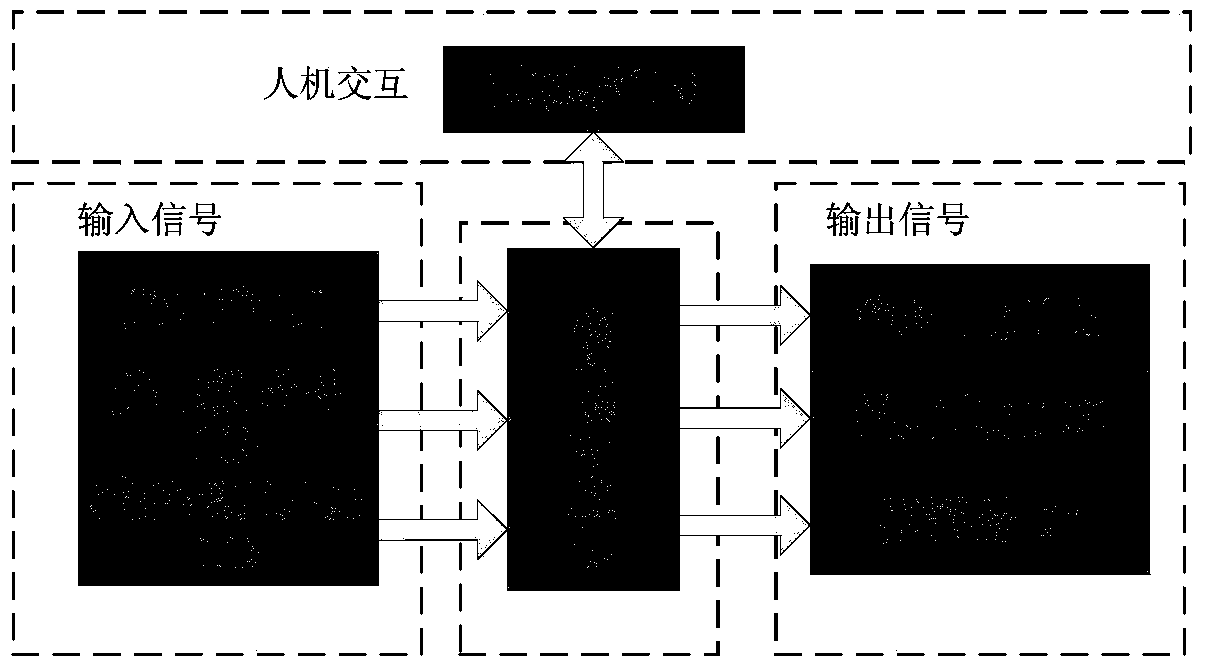

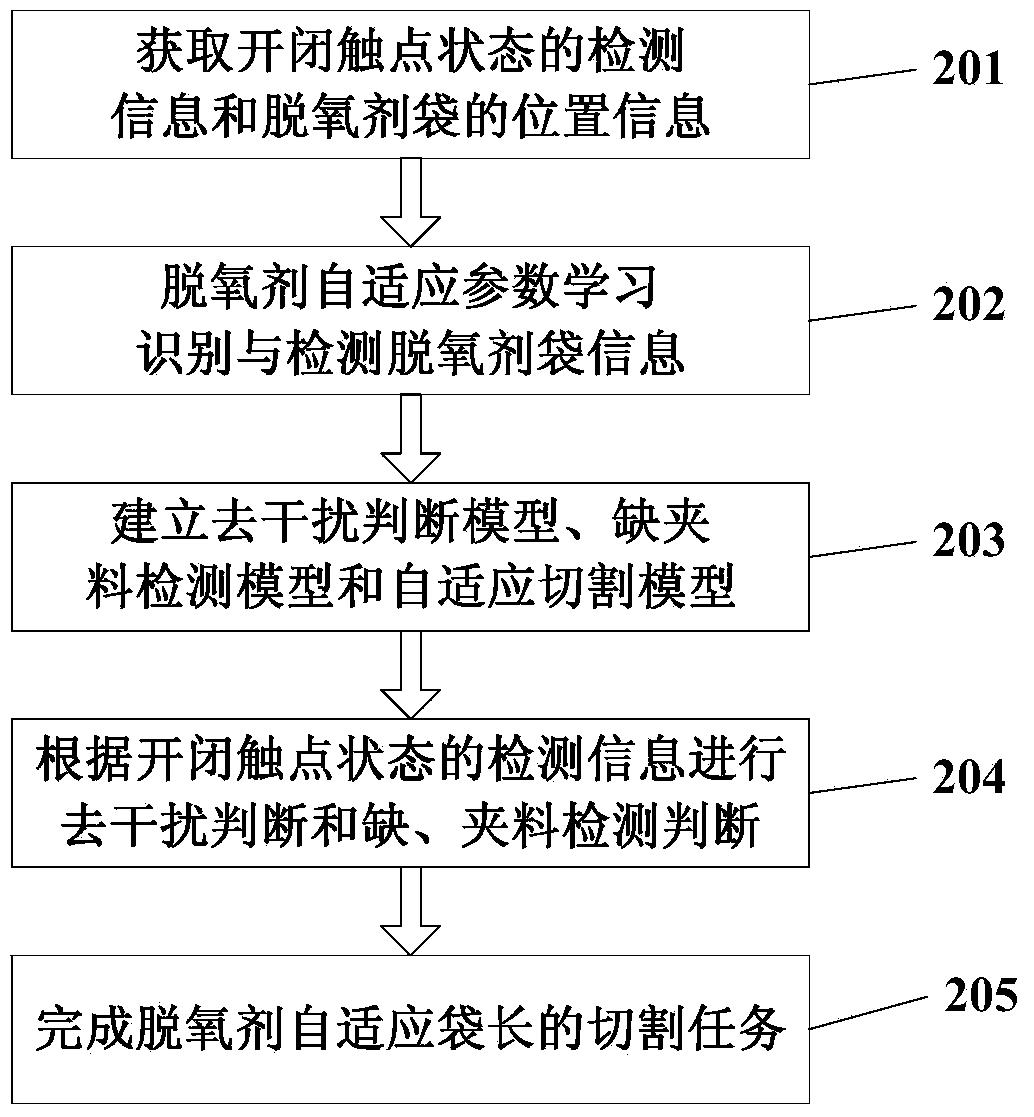

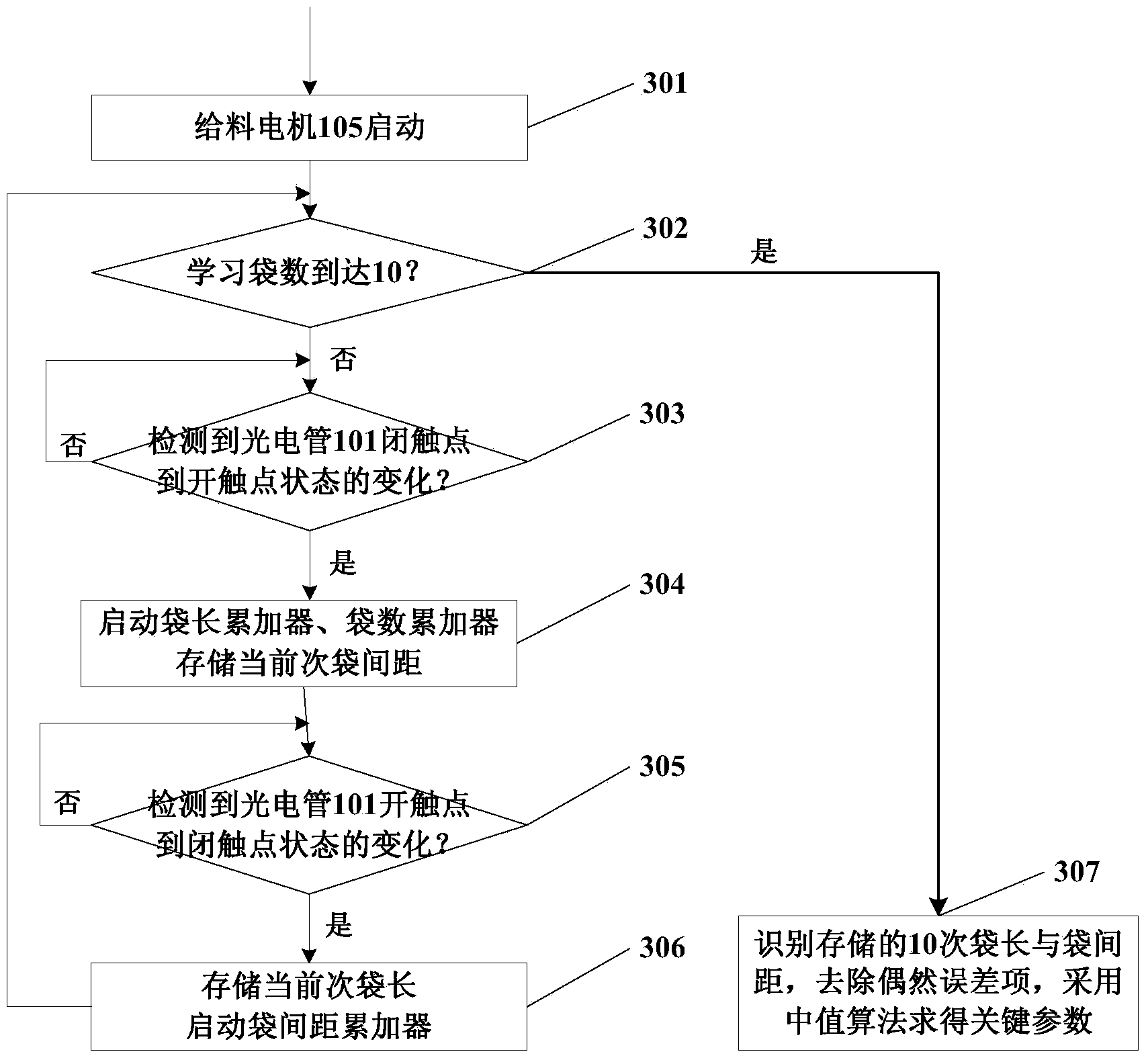

[0061] An application system of a deoxidizer self-adaptive bag length cutting and detection method for missing and sandwiched materials, such as figure 1 mentioned.

[0062] The signal input unit includes a photocell, a photoelectric encoder and a Hall proximity switch,

[0063] The photoelectric cell is installed at a distance L1 directly above the cutter, and the photoelectric cell is used to detect whether there is material in the deoxidizer, obtain the detection information of the open and close contact state, and send the detection information of the open and close contact state to the photoelectric Encoder and core controller;

[0064] The photoelectric encoder is used to obtain the position of the deoxidizer bag according to the detection information of the open and close contact state of the photoelectric cell, obtain the information of the deoxidizer bag, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com