Joints between jacking rods of reticulated shell of vaulted oil storage tank

A technology for storage tanks and reticulated shells, which is applied in the field of joints between the ejector rods of vaulted storage tank reticulated shells. It can solve the problems that affect the tight fit of the formed steel reticulated shell structure, the joint strength cannot meet the standard, and the installation is inconvenient. It achieves disassembly and assembly. Convenience and quickness, low installation cost and compact size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described.

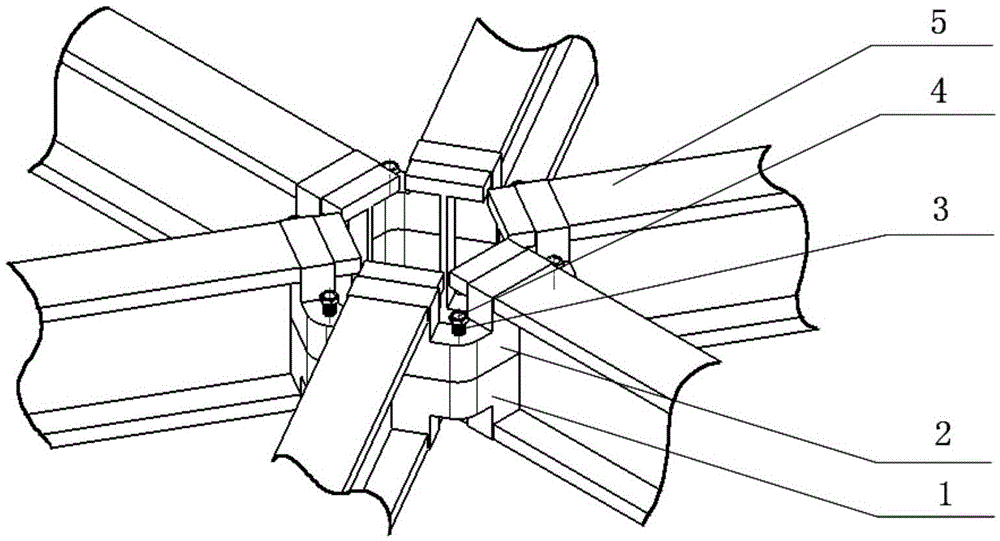

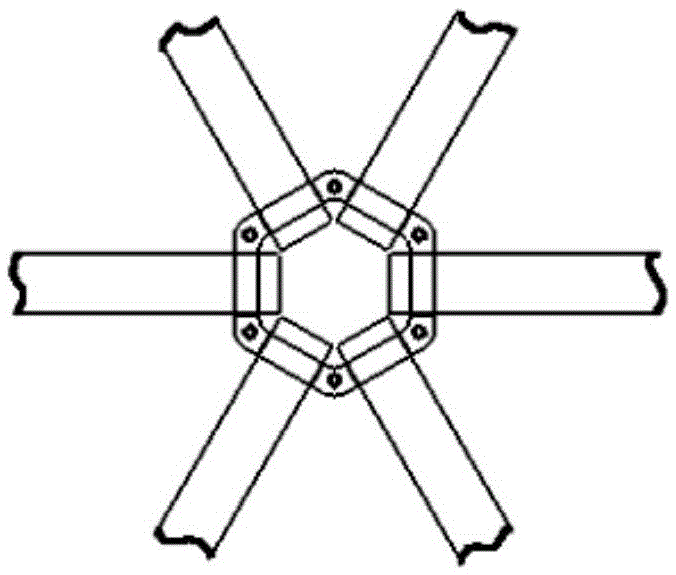

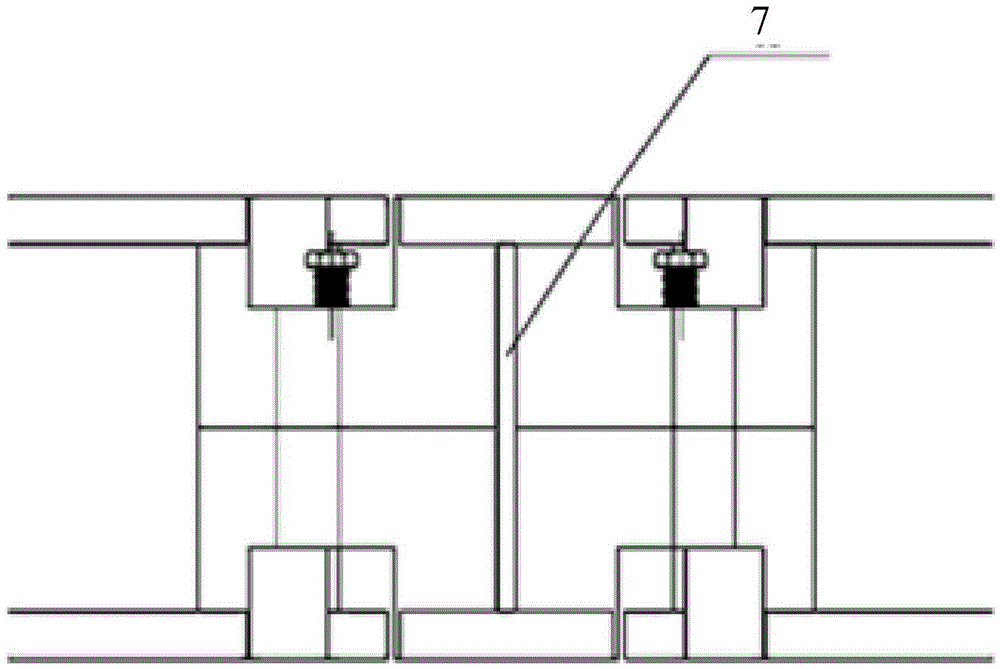

[0020] Such as figure 1 -As shown in 4 and 6, a joint between the top rods of the reticulated shell of the vault storage tank includes a lower plate body 1, an upper plate body 2, six bolts 3, six nuts 4, and six grooved formed steel 5; The disc body 1 and the upper disc body 2 are regular hexagonal annular structures symmetrical up and down, with threaded through holes 6 at the top corners of the hexagon, and a slit 7 at the midpoint of each side of the hexagonal structure. ;

[0021] Such as Figure 5 As shown, the grooved formed steel 5 is made up of a rib plate 51, two wing plates 52 of the same shape and size and two fixing blocks 53 of the same shape and size, and the two fixing blocks 53 are installed on the upper and lower sides of the left end of the rib plate 51 respectively. On both sides, two wing plates 52 are installed on the upper and lower sides of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com