Oxygen injector used for oxygen-enriched combustion

An oxygen-enriched combustion and oxygen injector technology, which is applied in the direction of combustion methods, combustion equipment, and non-flammable liquid/gas transportation, can solve the problems of uneven mixing of oxygen and flue gas or oxygen and air, so as to avoid incomplete combustion Stabilize and improve the effect of uneven mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

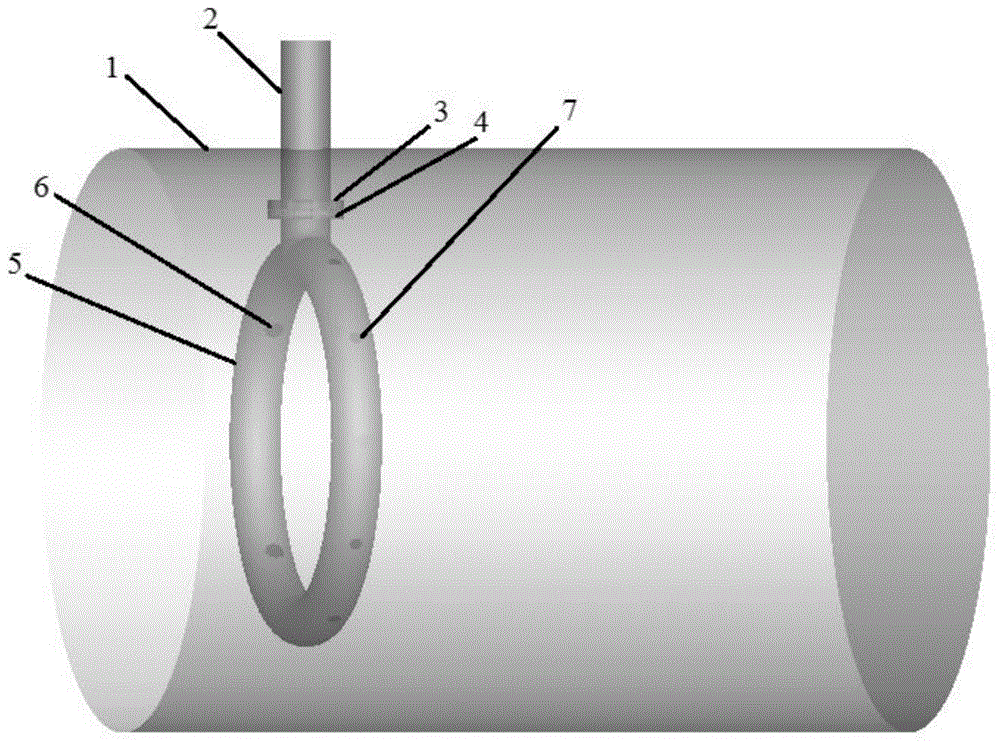

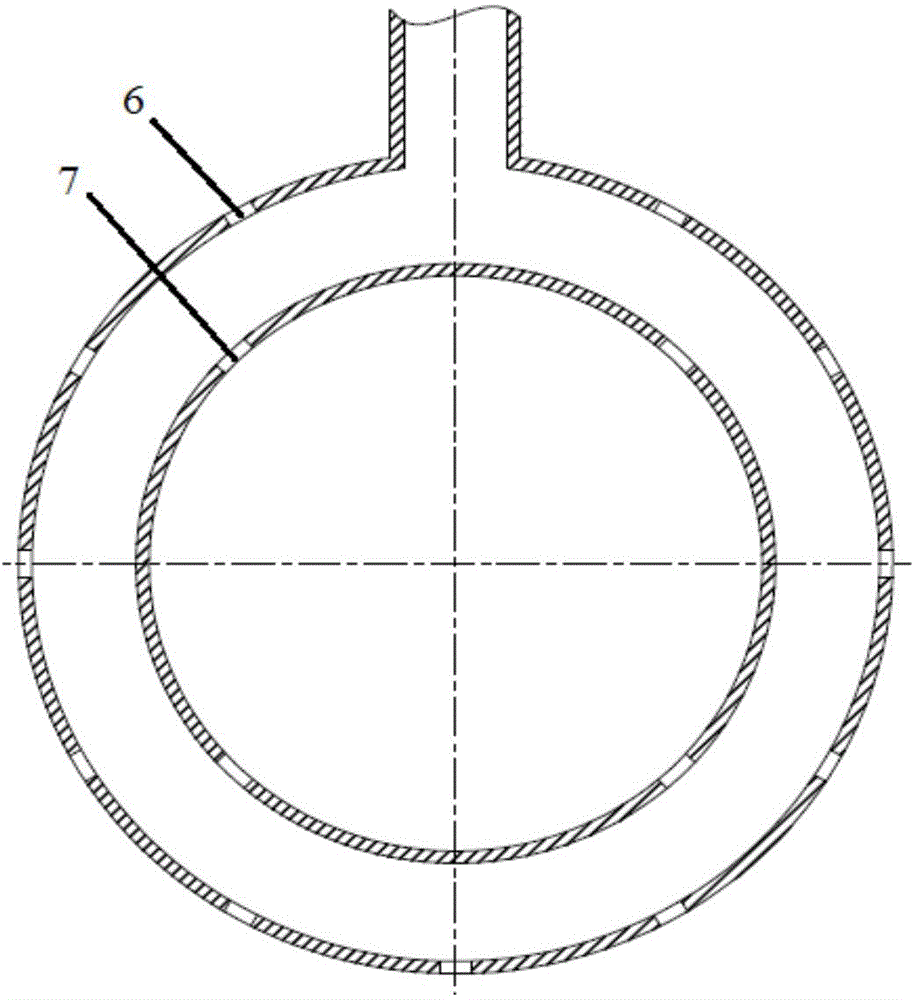

[0038] The oxygen injector of the present invention is used in a 200MW pulverized coal combustion boiler, and the circulating flue gas volume of the flue gas pipeline for oxygen injection is 108680m 3 / h, the total flow rate of injected oxygen is 18791m 3 / h, the inner diameter of the flue gas pipe is 1250mm, the diameter of the main oxygen pipe is 350mm, and the diameter of the oxygen direct pipe is 150mm. The oxygen is equally divided into four oxygen branch pipes through the main oxygen pipe. Oxygen is injected into the flue gas pipe during oxy-fuel combustion. Oxygen enters the four oxygen branch pipes from the main oxygen pipeline, then flows through the flowmeter and enters the oxygen direct pipe of the oxygen injector, and then is sprayed out through the replaceable oxygen injection ring pipe connected by the flange. The replaceable oxygen injection ring pipe The outer diameter of the ring is 0.8 times the inner diameter of the flue gas pipe, which is 1000mm; the cross...

example 2

[0040] Applying the present invention to a waste incineration grate furnace with a processing capacity of 350t / d, the primary air volume of the air pipeline for oxygen injection is 28717m 3 / h, the total flow rate of injected oxygen is 1500m 3 / h, the inner diameter of the air pipe is 920mm, and the diameter of the oxygen direct pipe is 80mm. During the oxygen-enriched incineration of garbage, oxygen is injected into the primary air duct. Oxygen enters the direct oxygen pipe of the oxygen injector from the oxygen pipe through the flowmeter, and then sprays out through the replaceable oxygen injection ring connected by the flange. The outer diameter of the replaceable oxygen injection ring pipe is 0.7071 times the inner diameter of the air pipe. The outer diameter of the cross-section of the oxygen injection ring pipe is the same as the diameter of the oxygen direct-flow pipe, which is 80mm; the diameter of the nozzle hole inside the oxygen injection ring is 0.37 times the out...

Embodiment 3

[0042] Applying the present invention to a waste incineration grate furnace with a processing capacity of 500t / d, the primary air volume of the air pipeline for oxygen injection is 41060m 3 / h, the total flow rate of injected oxygen is 2150m 3 / h, the inner diameter of the air pipe is 1100mm, and the diameter of the oxygen direct pipe is 95mm. During the oxygen-enriched incineration of garbage, oxygen is injected into the primary air duct. Oxygen enters the direct oxygen pipe of the oxygen injector from the oxygen pipeline through the flowmeter, and then sprays out through the replaceable oxygen injection ring pipe connected by the flange. The outer diameter of the replaceable oxygen injection ring pipe ring is 0.5 times the inner diameter of the air pipe , is 550mm; the cross-sectional diameter of the oxygen injection ring pipe should be selected to be the same as the diameter of the oxygen direct-flow pipe, which is 95mm; the diameter of the nozzle hole inside the oxygen in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com