Photographing device and electronic device with the photographing device

A shooting device and circuit board technology, which is applied in the electronic field, can solve the problems of limited wiring and layout space of the zoom camera module circuit board, limited heat dissipation design of the zoom camera module area, and the inability to apply ultra-thin mobile phones, etc., to achieve local solution Heat generation problem, saving wiring and layout space, and the effect of large wiring and layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

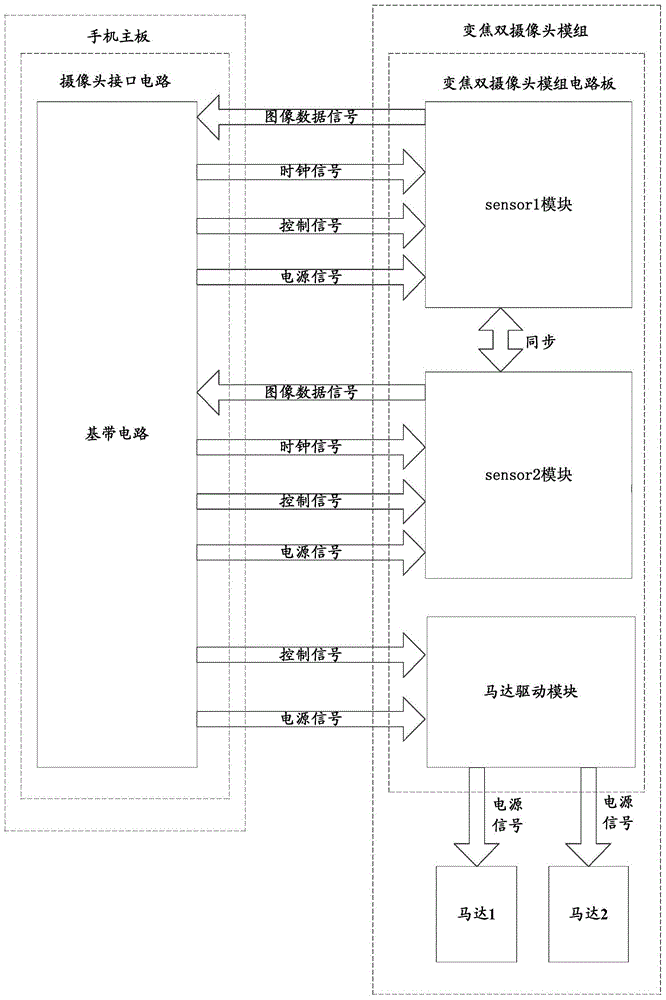

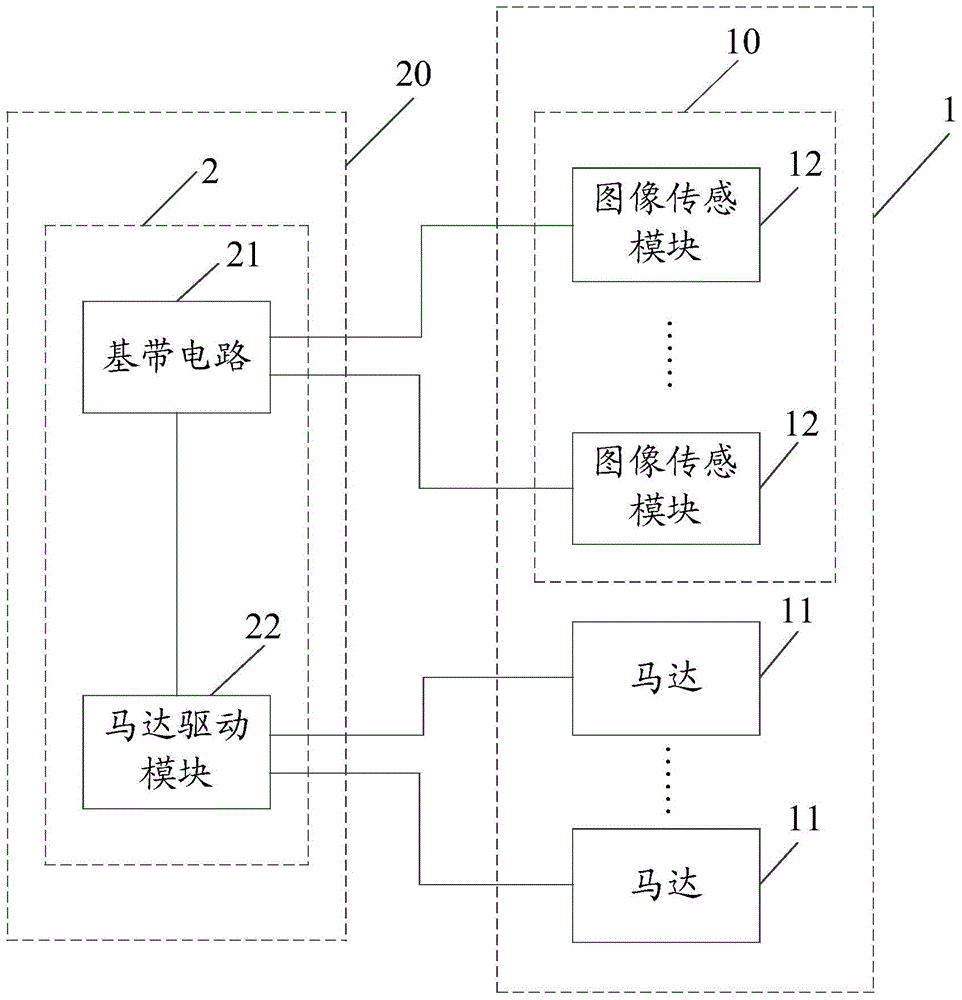

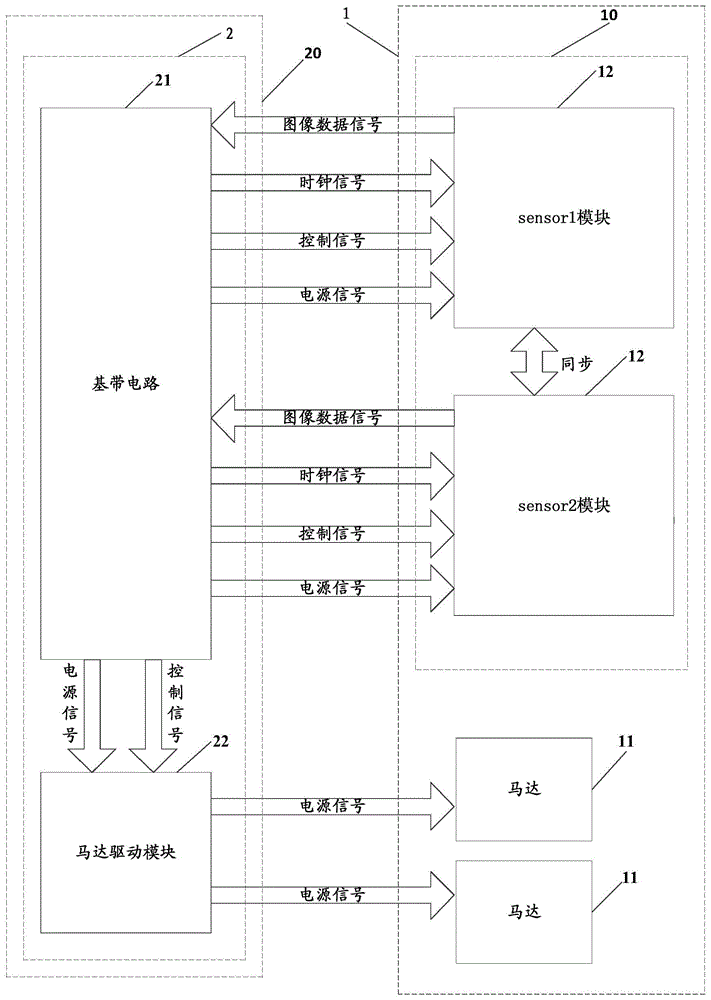

[0025] One of the core ideas of the embodiments of the present invention is that the camera module (such as a zoom dual camera module) does not include a motor driver module, but the motor driver module is arranged on a motherboard with good heat dissipation conditions, so that the related problems can be better solved. In the technology, the local heating problem of the camera module (such as the zoom dual camera module) and the interference problem of the motor drive module in the camera module to the image sensor module can also greatly save the wiring and layout space of the camera module circuit board .

[0026] refer to figure 2 , shows a structural block diagram of an embodiment of a photographing device according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com