Hydraulic system hydraulic cylinder structure meeting higher frequency response requirements and suitable for limited installation space

A technology of installation space and hydraulic system, which is applied in the field of hydraulic cylinders, can solve the problems of increasing the difficulty of component manufacturing, achieve optimal performance and cost, avoid external oil circuit design, and avoid the effect of installation design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

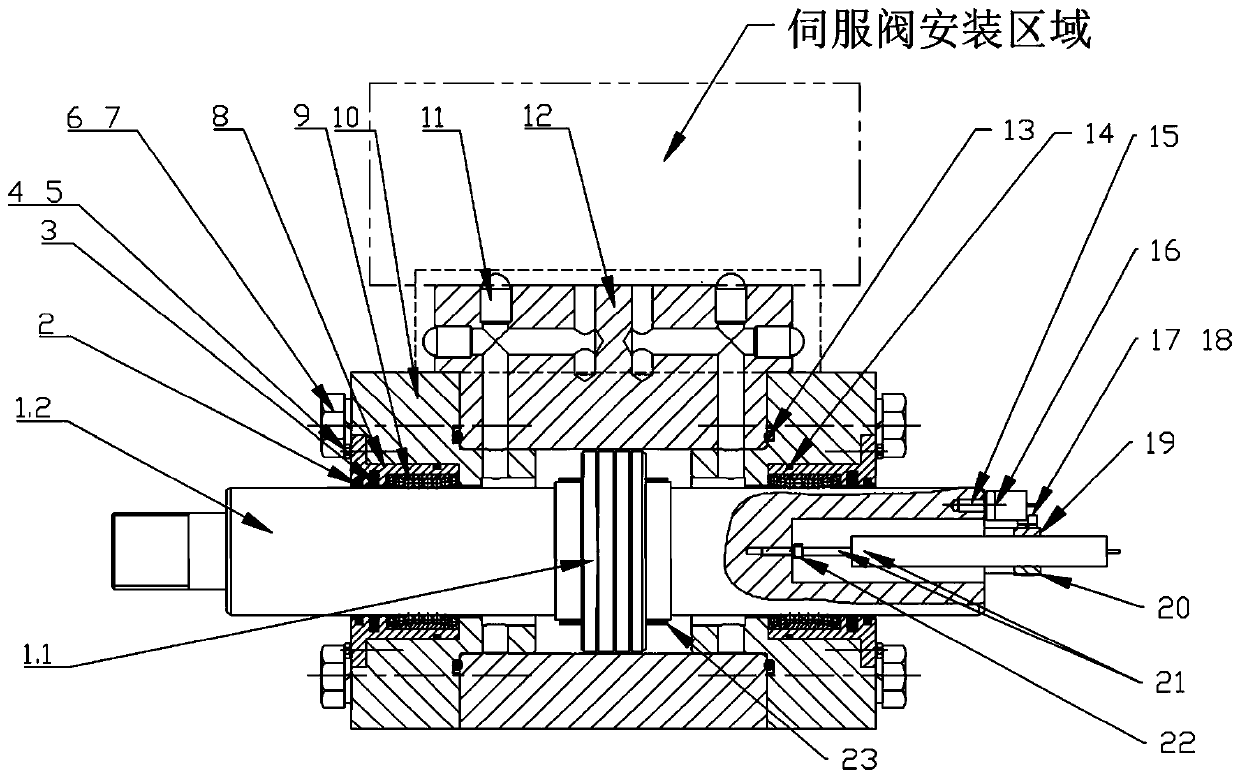

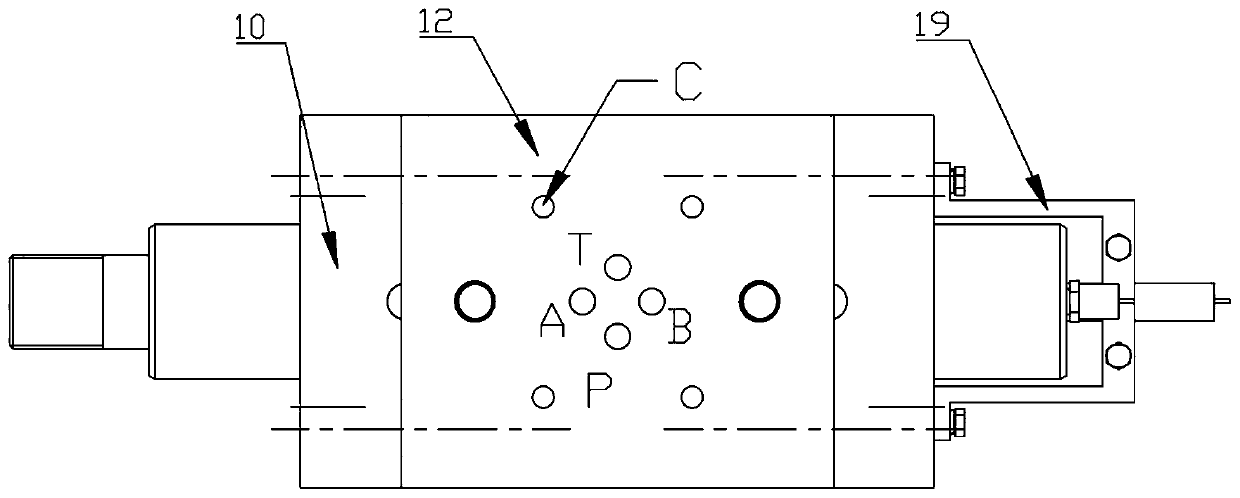

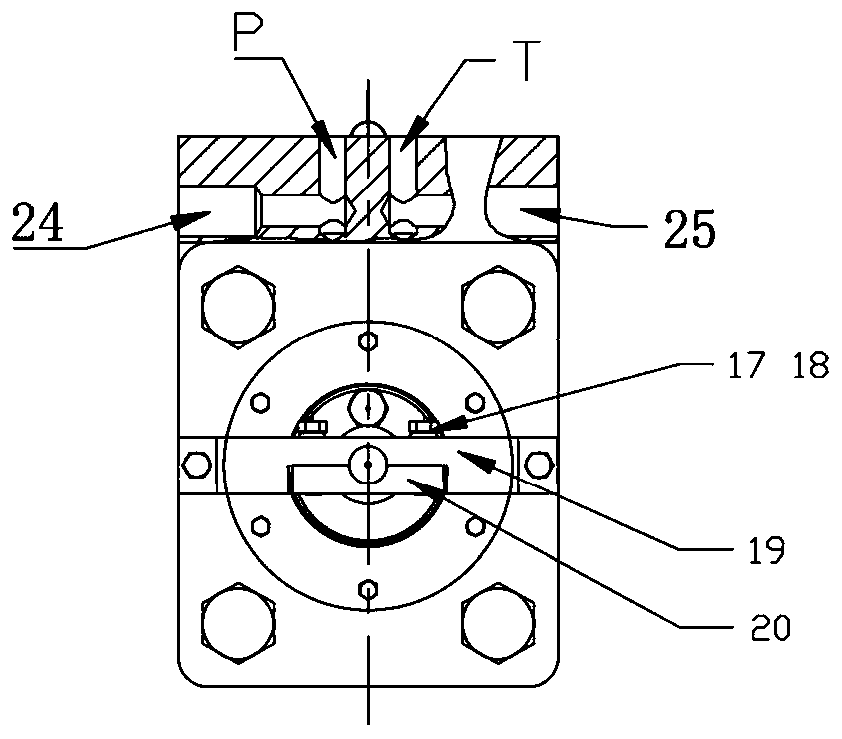

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Such as figure 1 As shown, the specific implementation of the present invention comprises piston block 1.1, piston rod 1.2, bearing sleeve 8, end cap 10, cylinder barrel 12; The two ends of cylinder barrel 12 are all equipped with annular end cap 10, and end cap 10 passes through the second The bolt 6 and the second washer 7 are fixedly installed on the end of the cylinder 12. There is a first sealing ring 13 between the cylinder 12 and the end cover 10 and is sealed by the first sealing ring 13. The two ends of the piston block 1.1 are fixed coaxially. Connect the piston rod 1.2, the piston block 1.1 is installed in the cylinder barrel 12, the dynamic seal between the piston 1.1 and the cylinder barrel 12 adopts a gap seal, and the piston 1.1 is provided with a pressure equalizing groove. The piston rod 1.2 is installed in the end cover 10, and the piston blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com