Cross-cutting instrument sensor traction method in road broadening subgrade

A technology of sensors and cross-section instruments, which is applied in the field of traction of cross-section instrument sensors, can solve the problems that the traction line cannot be pulled for testing, and the cross-section instrument cannot be applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

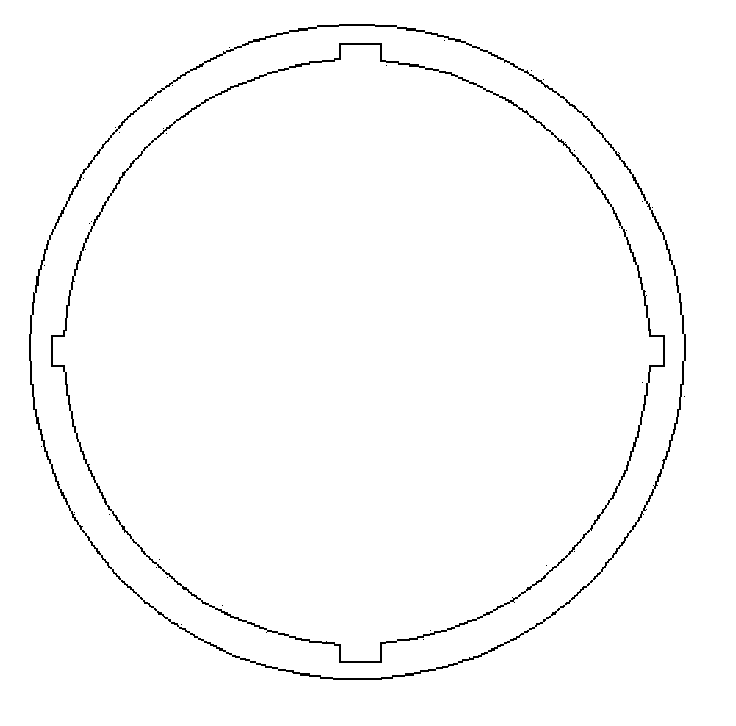

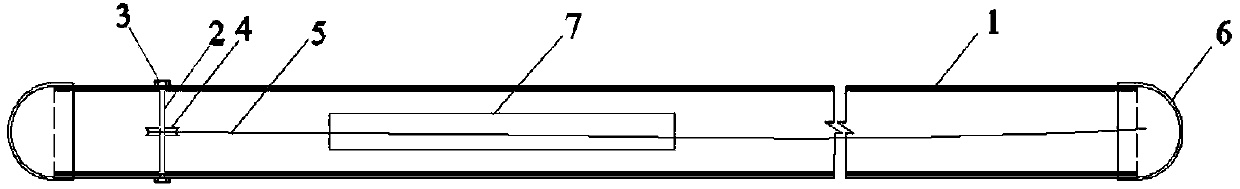

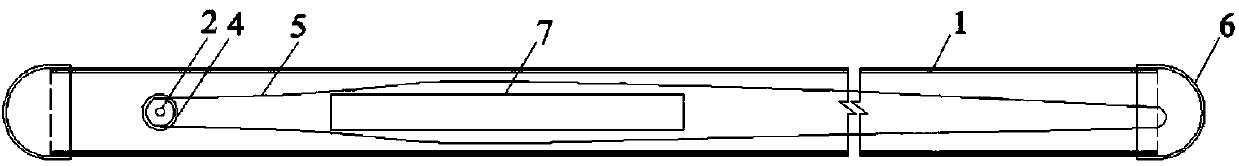

[0027] The present invention has used the improved cross-section pipe when carrying out the traction of the cross-section instrument sensor, as figure 2 and image 3 As shown, the method for pulling the transversometer sensor in the road widening subgrade of the embodiment of the present invention is carried out according to the following steps:

[0028] Step 1, according to the width of the widened subgrade, prepare a cross-section pipe 1 with the same length as the width of the subgrade, and set a group of bolts corresponding to the upper and lower sides at a distance of 5 cm to 10 cm (preferably 10 cm) from the nozzle of the cross-section pipe on the side of the old road subgrade hole and install a piercing bolt 2, the two ends of the piercing bolt 2 are fixed to the pipe wall of the cross-section pipe 1 through the nut 3, and at the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com