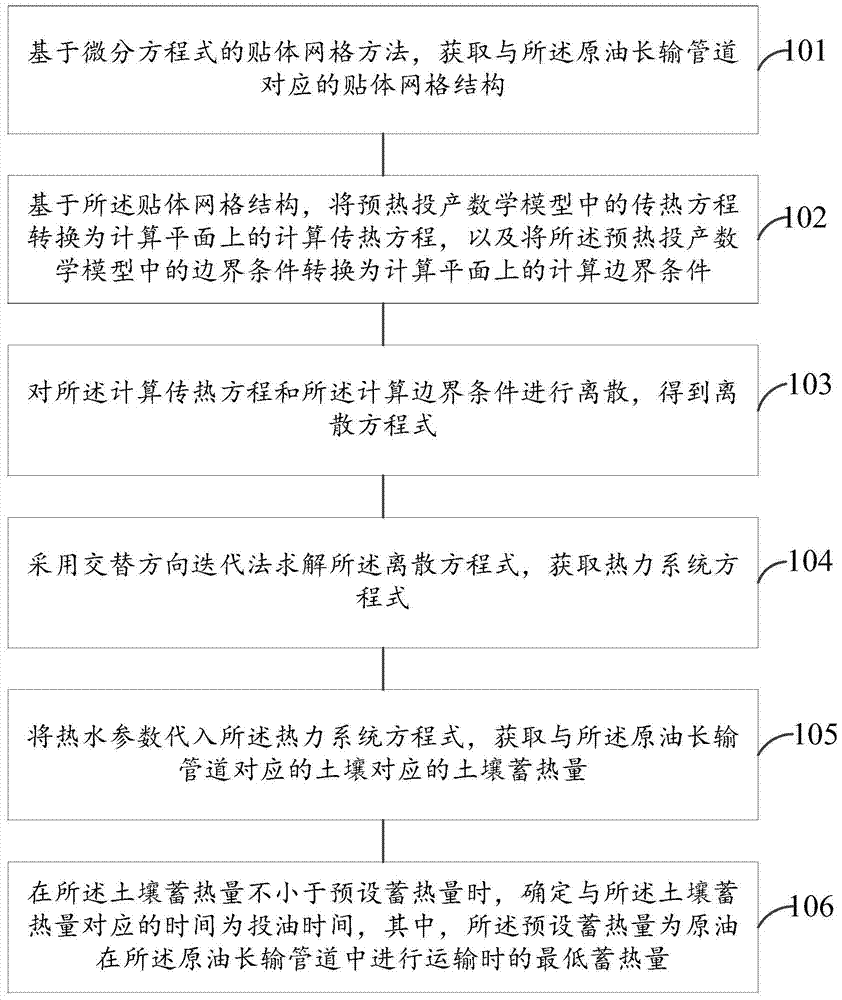

A Preheating and Production Unsteady Prediction Method for Waxy Crude Oil Long-distance Pipeline

A technology for long-distance pipelines and prediction methods, which is applied in special data processing applications, instruments, electrical and digital data processing, etc. Application value, good fit of boundary conditions, the effect of shortened calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention provides an unsteady-state prediction method for preheating and putting into production of a long-distance waxy crude oil pipeline, which can effectively reduce the amount of calculation, shorten the calculation time, and the accuracy can meet the actual need of putting into production, and has high engineering application value.

[0051] The implementation process of the existing waxy crude oil long-distance pipeline preheating and commissioning mathematical model is as follows:

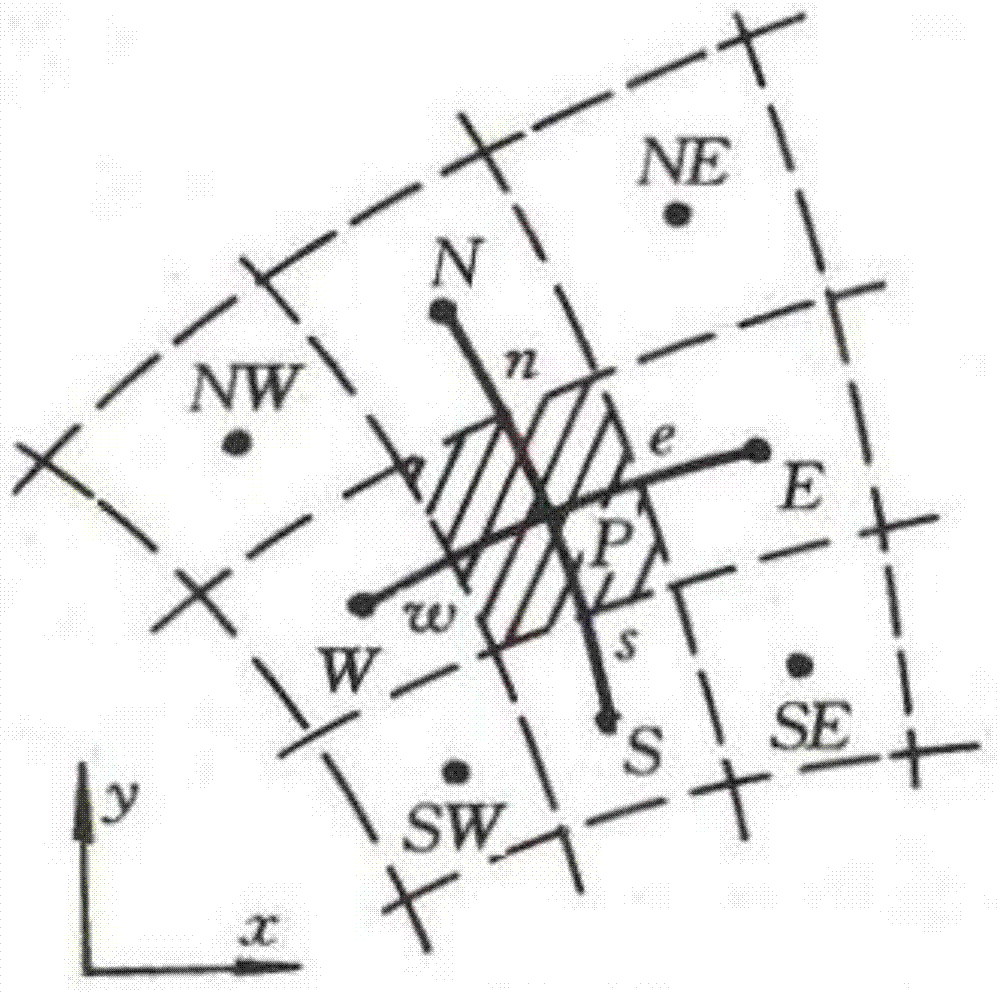

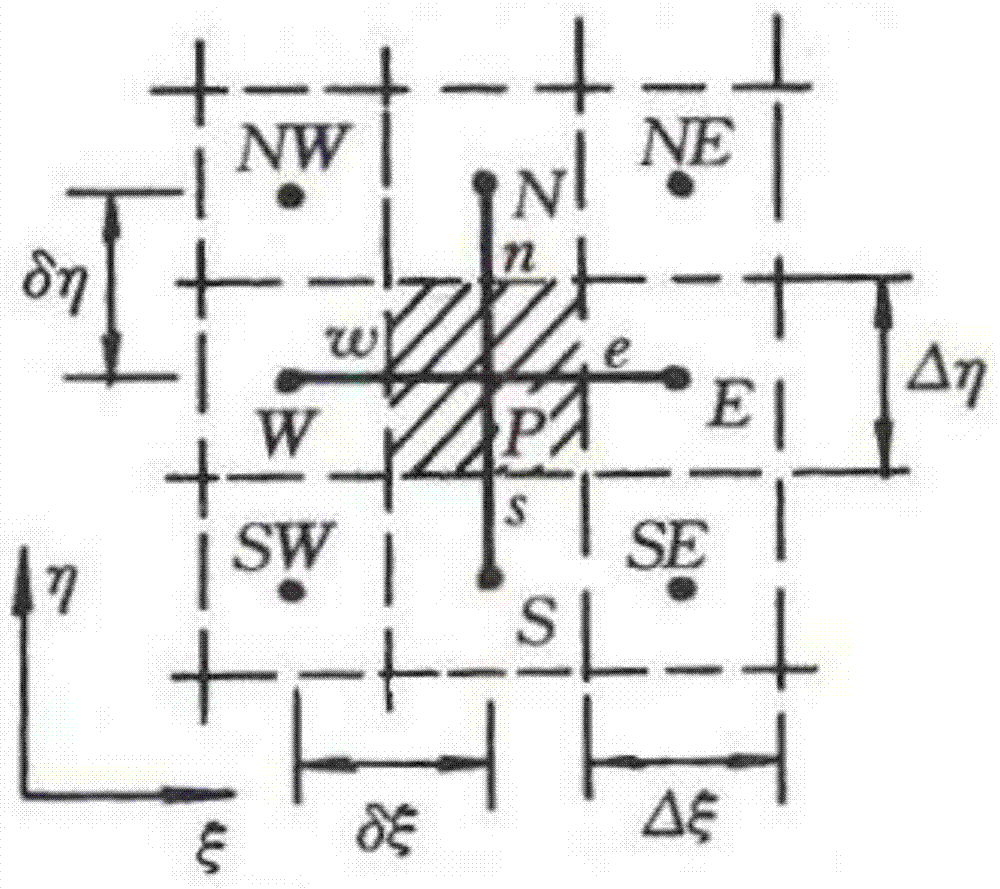

[0052] Theoretically speaking, the temperature change process of the medium in the pipe and the surrounding soil during the unsteady operation of the pipe is a three-dimensional unstable heat transfer problem along the cross-section (radial and tangential) and axial direction of the pipe. However, in engineering applications, according to different needs, it is often simplified to a two-dimensional or one-dimensional heat transfer problem for numerical simulation. Considering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com