Cable connection device and method

A cable connection and cable technology, applied in the direction of cable joints, etc., can solve the problems of air gap breakdown, easy generation of air gap, long installation time, etc., to reduce the possibility of breakdown voltage, reduce the generation of air gap, and shorten the installation time the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core of the present invention is to provide a cable connection device, which can eliminate the air gap generated when connecting cables in the prior art, thereby avoiding the formation of electric trees, discharge along the surface and even breakdown, and greatly improve the cable operation. level of security. Another core of the present invention is to provide a cable connection method capable of achieving the above technical effects.

[0029] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

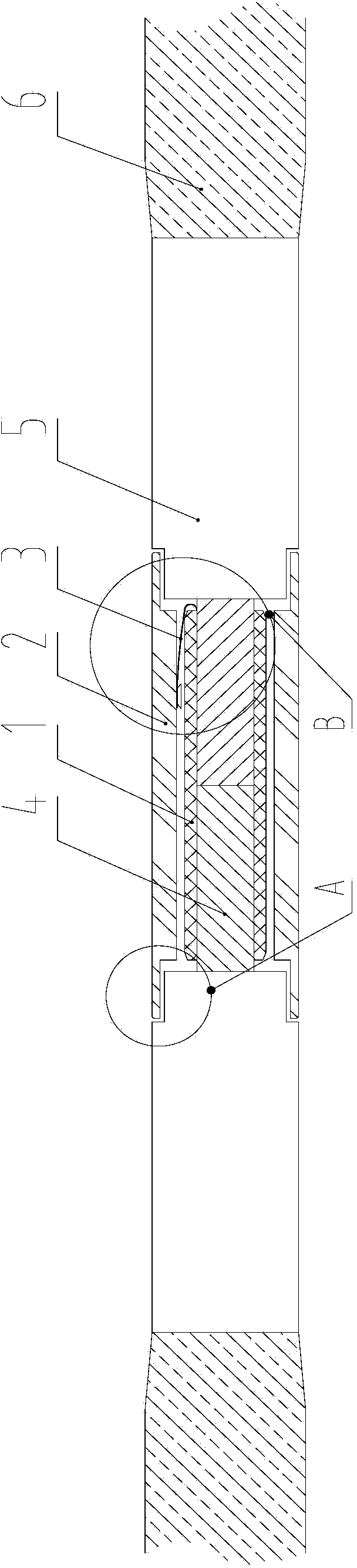

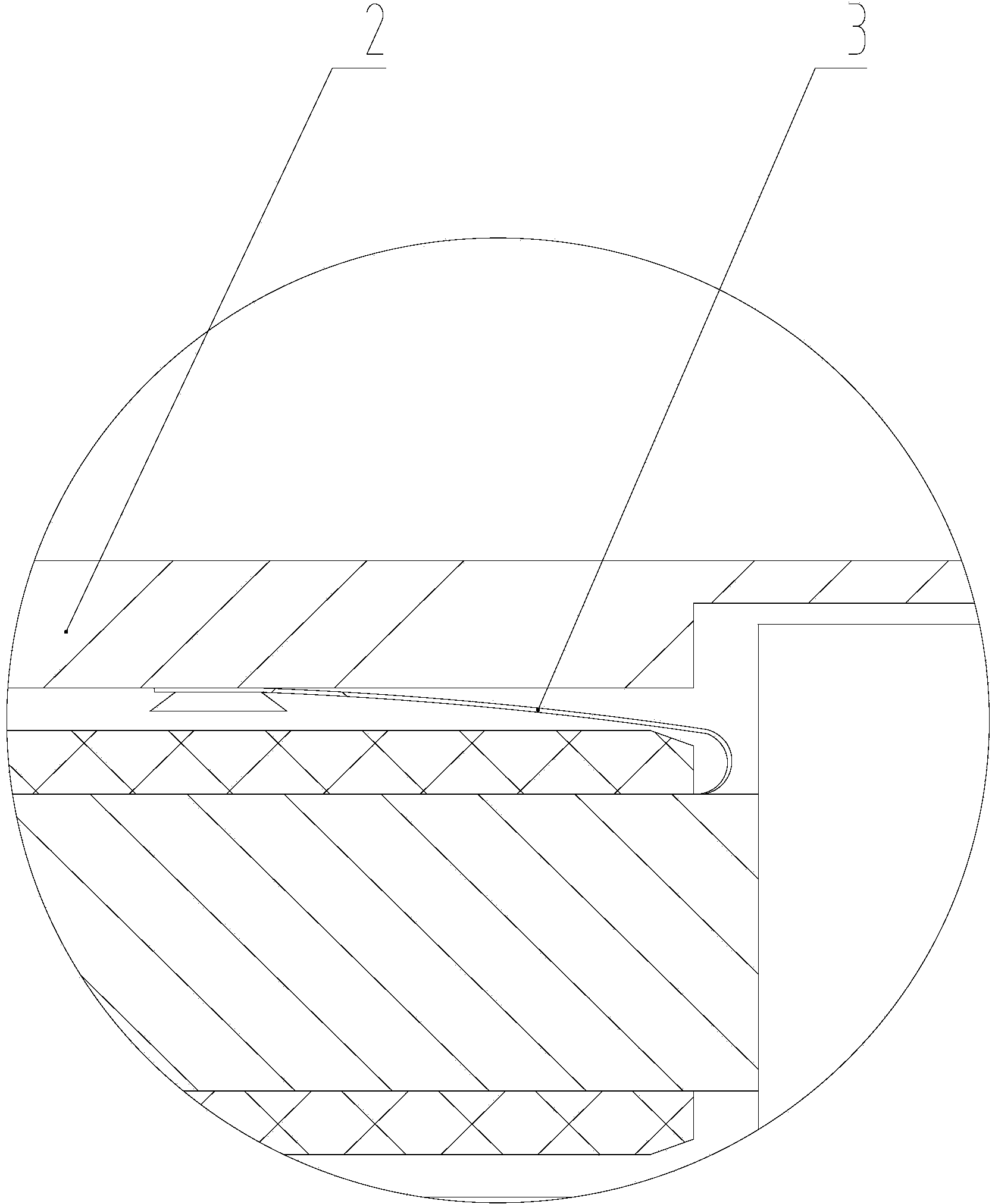

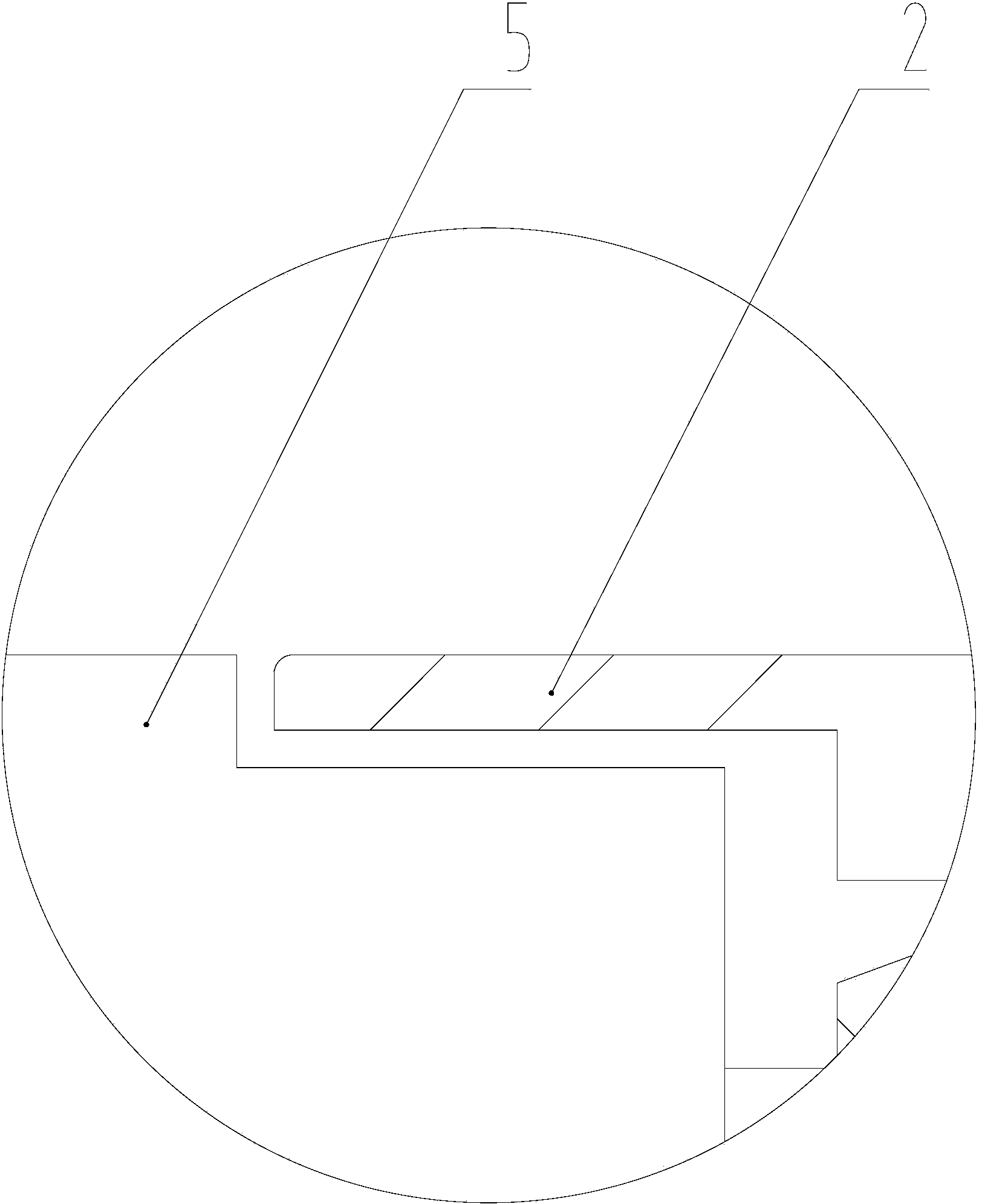

[0030] Please refer to figure 1 , is a structural schematic diagram of a specific embodiment of the cable connection device provided by the present invention.

[0031] In a specific embodiment, the cable connection device provided by the present invention has a connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com