Piezoelectric ceramic driving device

A piezoelectric ceramic drive, piezoelectric ceramic technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as environmental noise impact, and achieve cost reduction , Improve the output displacement resolution, improve the effect of positioning resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

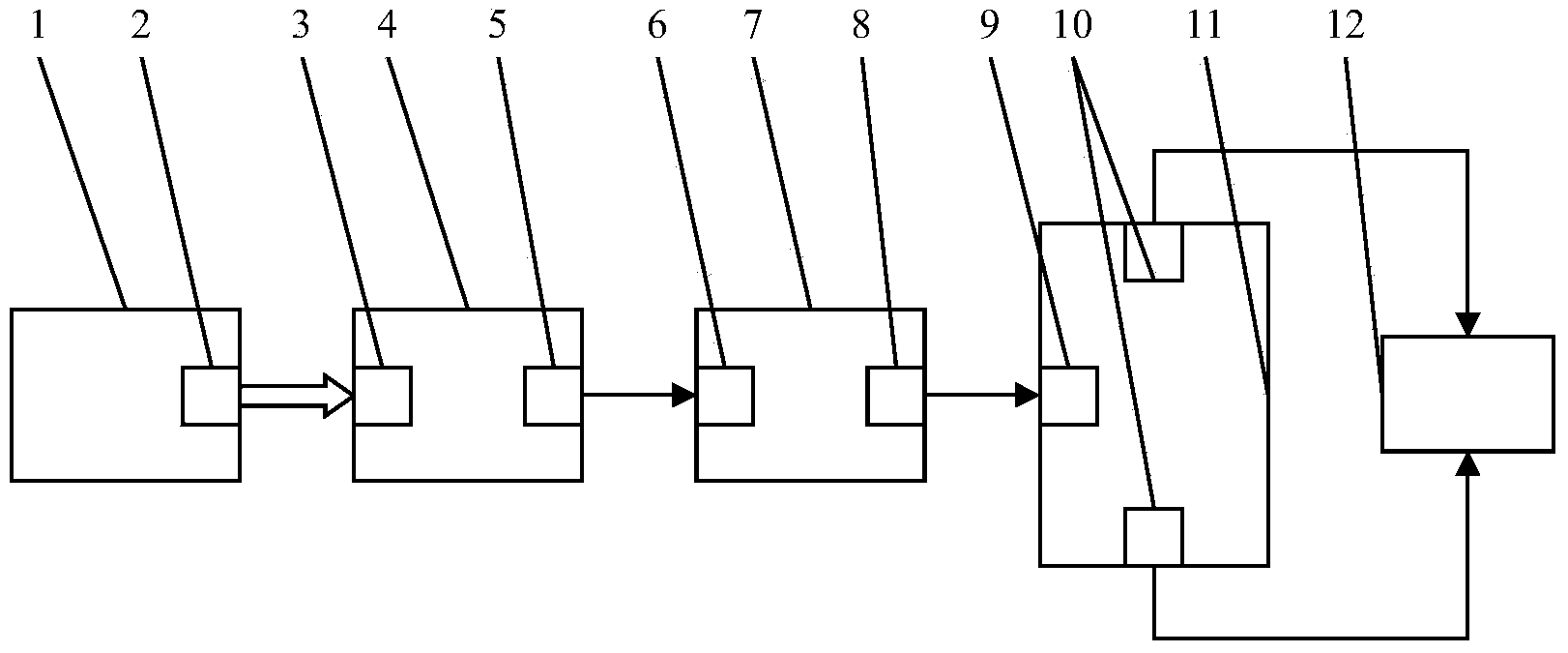

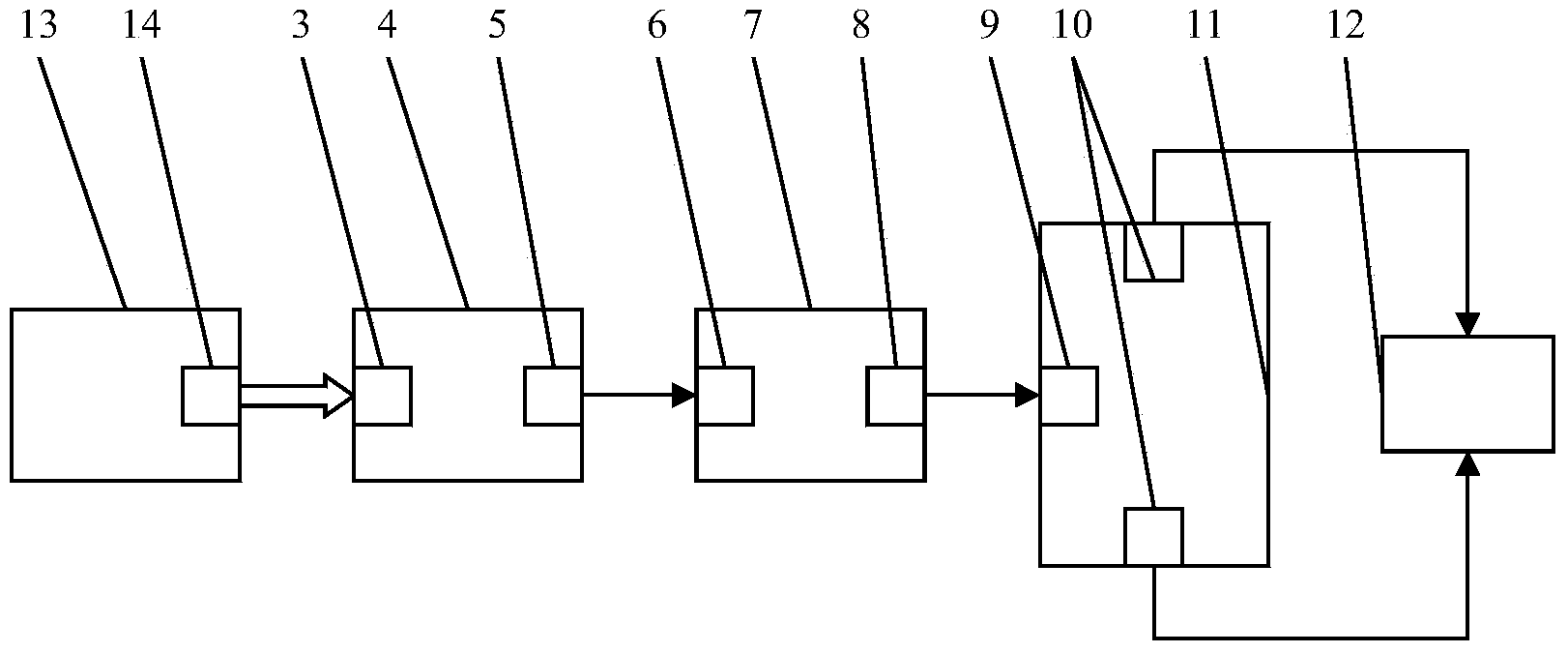

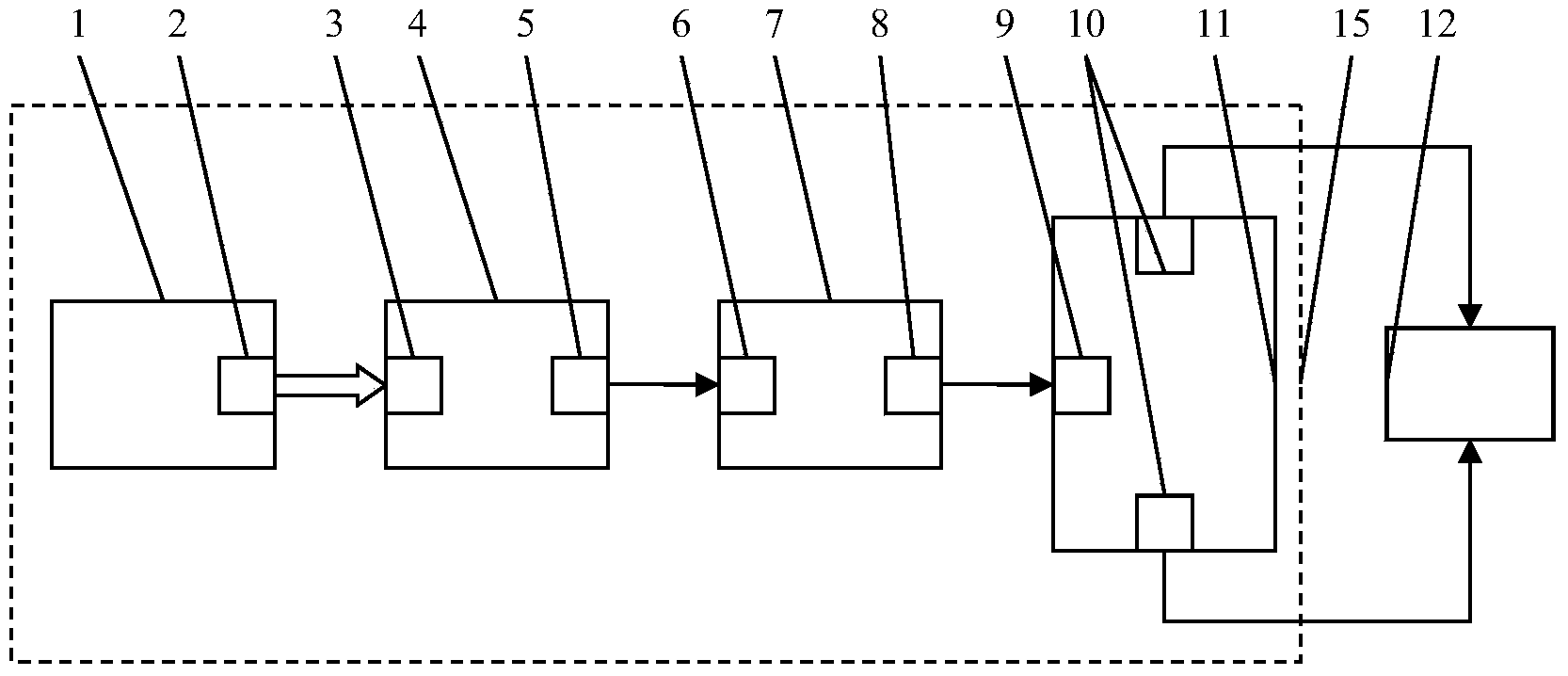

[0014] Specific implementation mode 1. Combination Figure 1 to Figure 5 Describe this embodiment, the piezoelectric ceramic driving device includes a digital-to-analog converter 4, a voltage amplifier 7 and a differential driver 11; wherein the analog signal output terminal 5 of the digital-to-analog converter is connected to the signal input terminal 6 of the voltage amplifier, and the voltage amplifier's The signal output terminal 8 is connected to the signal input terminal 9 of the differential driver, and the signal output terminal 10 of the differential driver is connected to the piezoelectric ceramic 12; the digital signal becomes an analog voltage signal after being converted by the digital-to-analog converter 4; the analog voltage signal is passed through the voltage amplifier 7 is amplified and transmitted to the differential driver 11; the differential driver 11 applies the voltage to both ends of the piezoelectric ceramic 12.

[0015] This embodiment also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com