System and method for steady state simulation of rolling tire

A technology of tires and models, which is applied in the direction of automobile tire testing, vehicle testing, special data processing applications, etc., and can solve the problem of high cost of computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

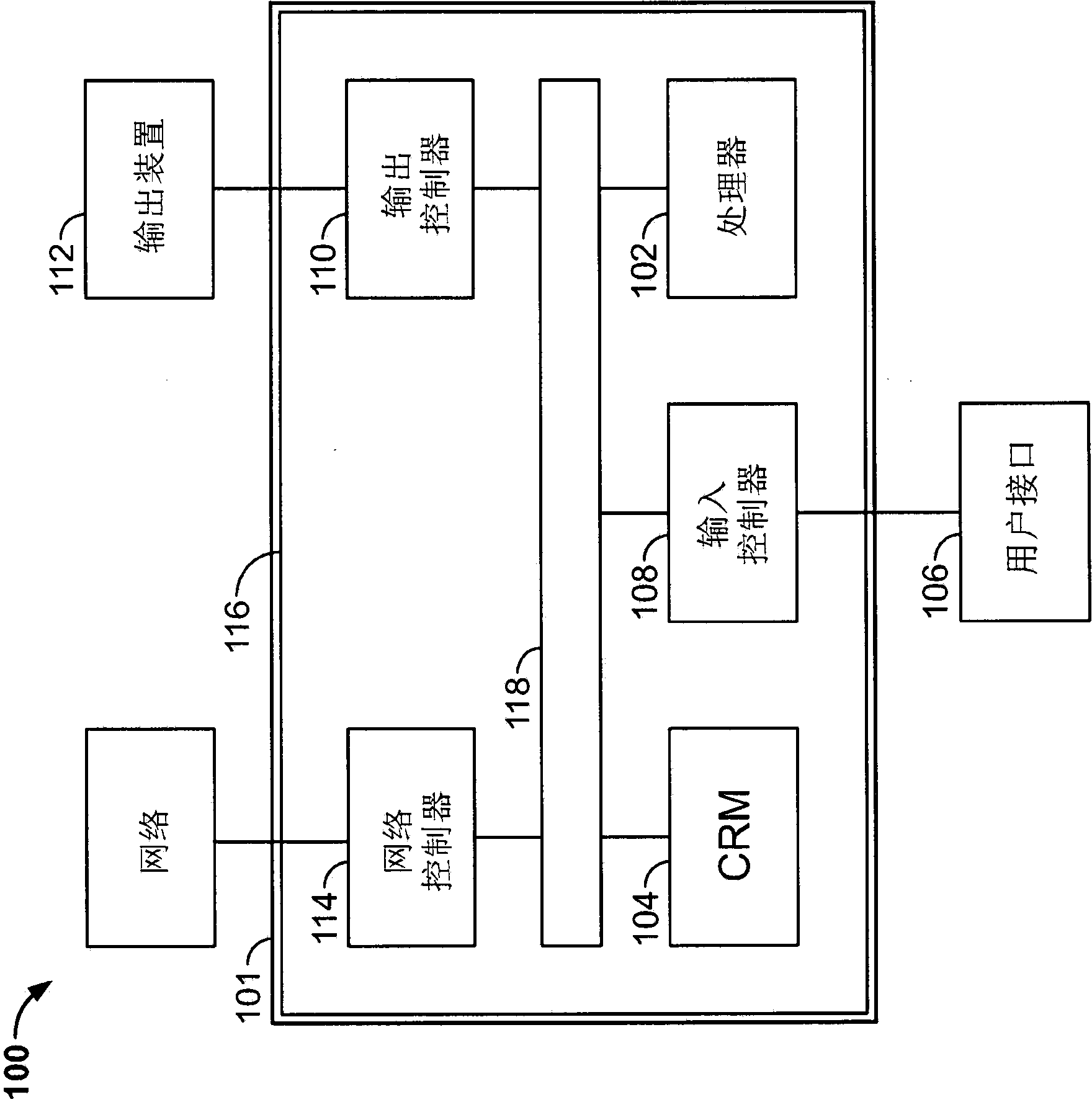

[0019] figure 1 A block diagram of an exemplary finite element analysis (FEA) processing system 100 is shown. FEA processing system 100 may include a computing device 101 housing a processor 102 and a computer-readable medium 104 . A user interface 106 , such as a keyboard, mouse, or other such device, is connected to an input controller 108 that allows a user to interact with the FEA system 100 , including with the processor 102 and the computer-readable medium 104 . Output controller 110 may receive information from input controller 108, processor 102, and / or computer-readable medium 104 for presentation to a user via output device 112, which may take the form of, for example, a video monitor or a printer. The computer-readable medium 104 may take the form of, for example, a hard drive, a solid-state drive, or a read-only memory (“RAM”), and may provide information to any component of the FEA processing system 100 . Network controller 114 allows FEA system 100 to communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com