A turbo-pressurized sand-water separation and filtration device

A technology of turbo pressurization and filtration device, which is applied in filtration separation, separation method, moving filter element filter, etc. The effect of enhancing liquidity and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

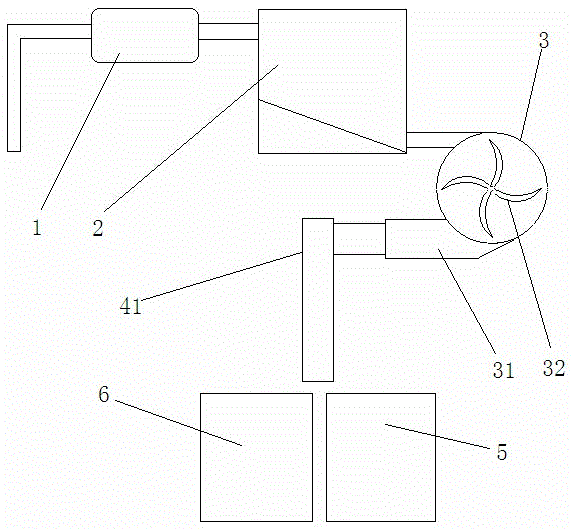

[0034] Such as figure 1 As shown, a turbo-pressurized sand-water separation and filtering device of the present invention includes a water pump 1, a water storage tank 2, a turbo-pressurizing device 3, and a sediment filtering device connected in series by water pipes. The above devices are generally arranged in combination. Used on collection devices;

[0035] The turbocharging device 3 has a circular structure, and the turbocharging device 3 has a discharge port guide part 31 facing the water flow, and the discharge port guide part 31 is located at a circular tangent line outside the turbocharging device 3 , After the sand and water are pressurized, there is no hindrance in the flow direction, and the relatively straight water pipe channel environment can also avoid the sedimentation of sand in the water pipe to a certain exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com