Metal pipe welding device

A welding device and metal pipe technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as increasing the difficulty of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

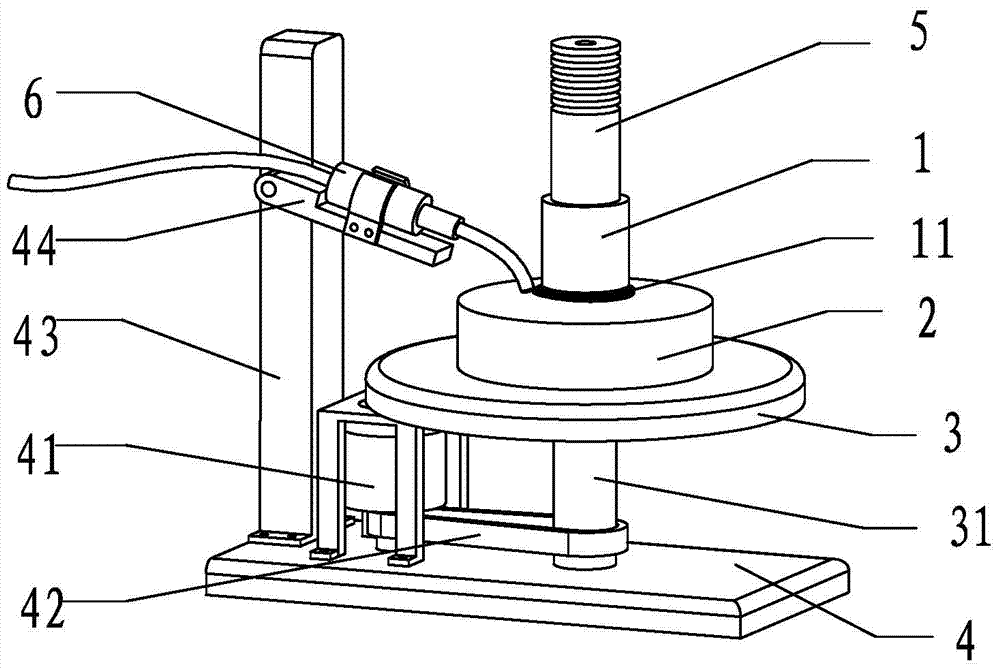

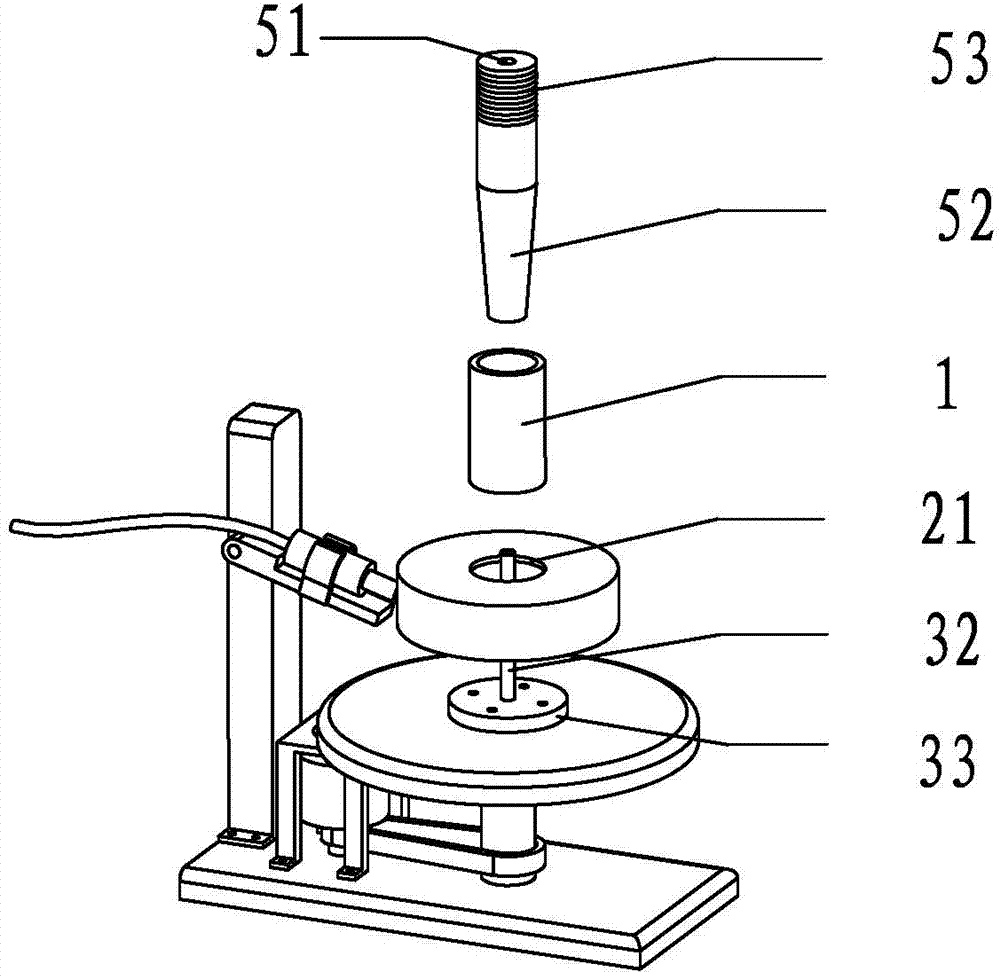

[0013] like Figure 1 to Figure 2 As shown, a metal pipe welding device, the metal pipe 1 is inserted into a base workpiece 2 provided with a central hole 21 for outer ring welding, the outer wall of the metal pipe and the inner wall of the central hole are fitted with a clearance, and the general clearance is not large. If the gap exceeds 1mm, the gap setting is too large, which will easily lead to large welding errors. If the gap is too small, the metal pipe is not easy to put into the center hole. In this example, the base workpiece is a flange, and of course it can be replaced with other shapes. The base workpiece described above is placed on a disc 3, a rotating shaft 31 is fixed vertically at the bottom of the disc, the bottom of the rotating shaft is hinged on a base plate 4, a motor 41 is arranged on the base plate, and a motor frame is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com