Double-group and semi-automatic cover plate assembly machine for flat plate heat collectors

A flat-plate collector, semi-automatic technology, applied in the direction of manipulator, metal processing, metal processing equipment, etc., can solve the problems of affecting production capacity and workers' work mood, heavy moving parts of assembly machines, low efficiency and production capacity, etc., to achieve long-term reliability. The effect of easy work, process and position adjustment, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is the best example of the double-group semi-automatic cover plate assembly machine for flat plate collectors described in the present invention, and does not limit the scope of protection of the present invention.

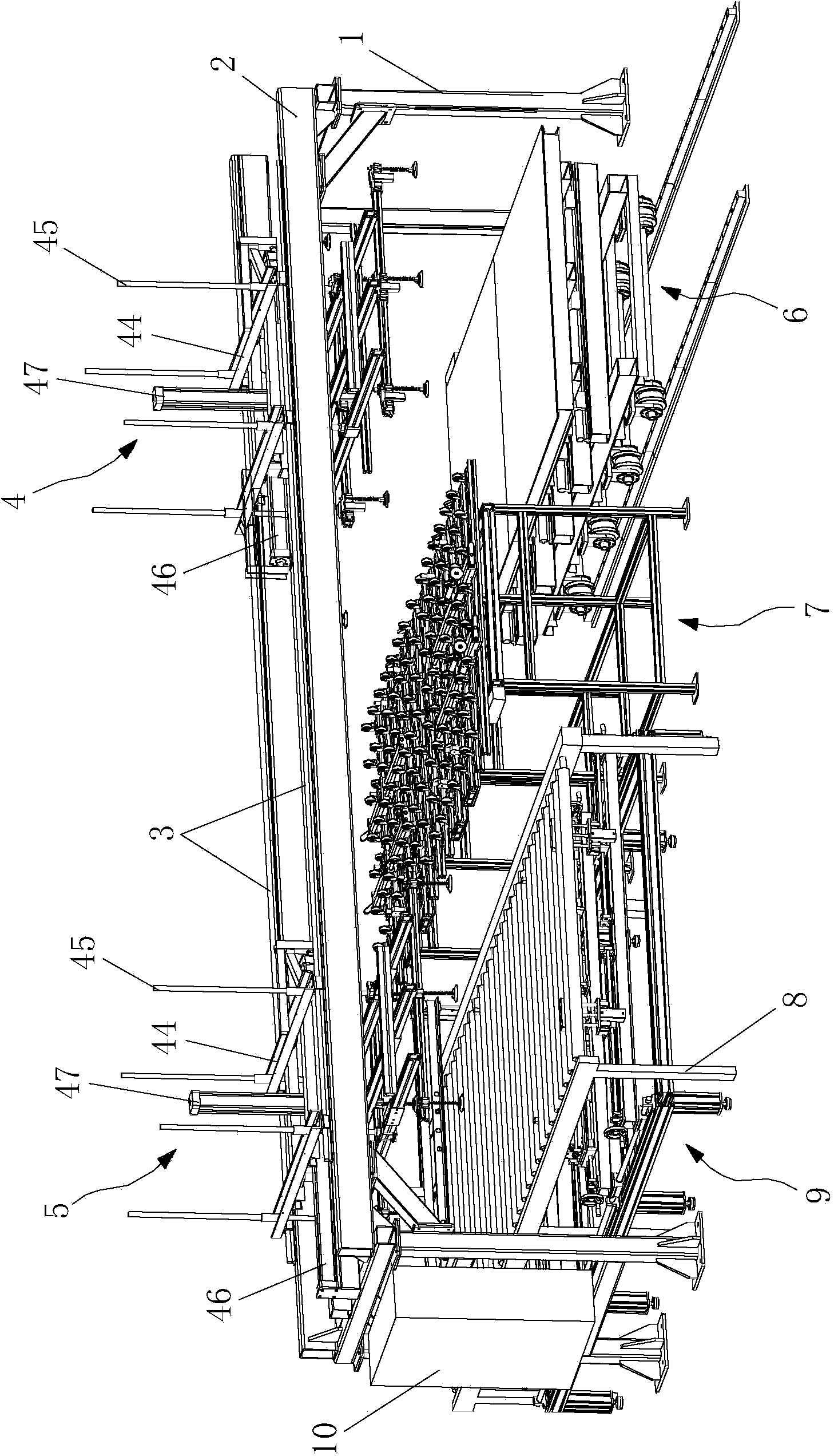

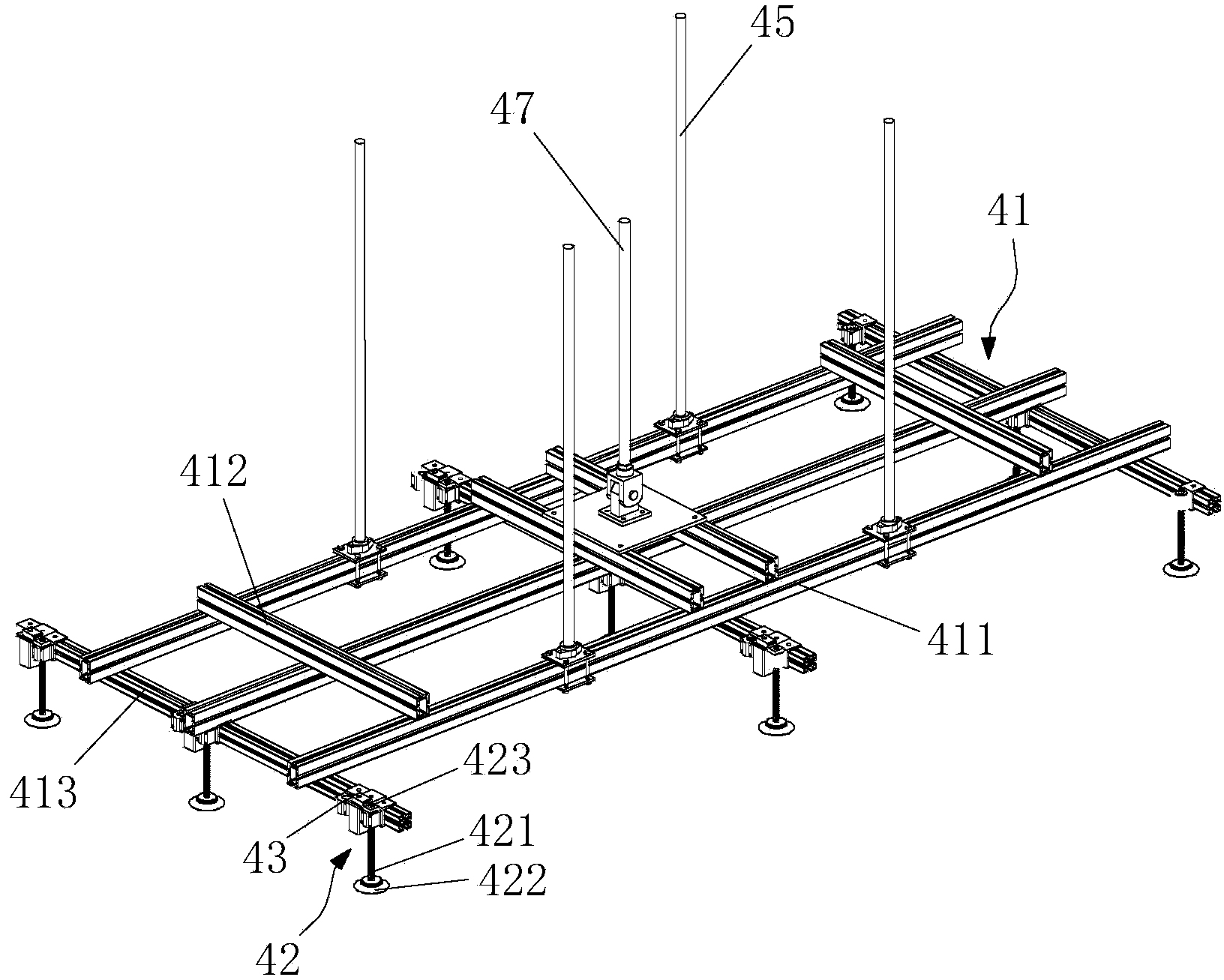

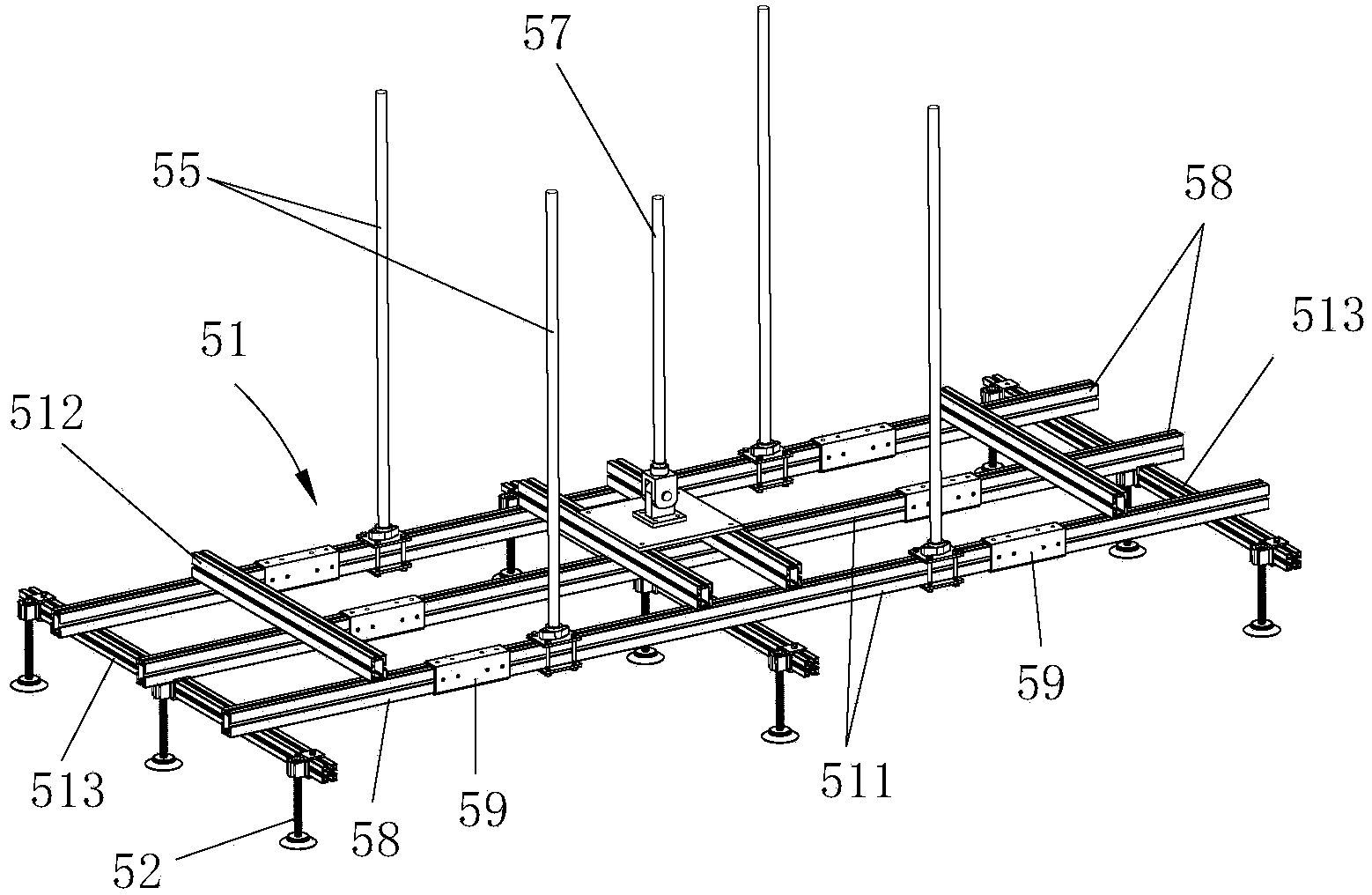

[0030] Please refer to figure 1 , the figure shows a double-group semi-automatic cover plate assembly machine for flat-plate collectors, including a frame 1, a first beam 2 installed on the upper part of the frame 1, and a first guide rail installed on the first beam 2 3. The first guide rail 3 is equipped with an adjustable cover plate grabbing mechanism 4 and an adjustable cover plate assembly mechanism 5 that can move along the first guide rail 3, and an adjustable cover plate loading vehicle 6 installed under the first beam 2 , an adjustable cover plate positioning mechanism 7 and a production line support 8, the bottom of the assembly area of the production line support 8 is equipped with an adjustable frame positioning mechanism 9 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com