Water flow power generating device

A water flow power generation and generator technology, which is applied in the field of water flow power generation devices and hydroelectric power generation devices, can solve problems such as low power generation efficiency, and achieve the effects of avoiding radial loss of water flow, improving efficiency, and reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

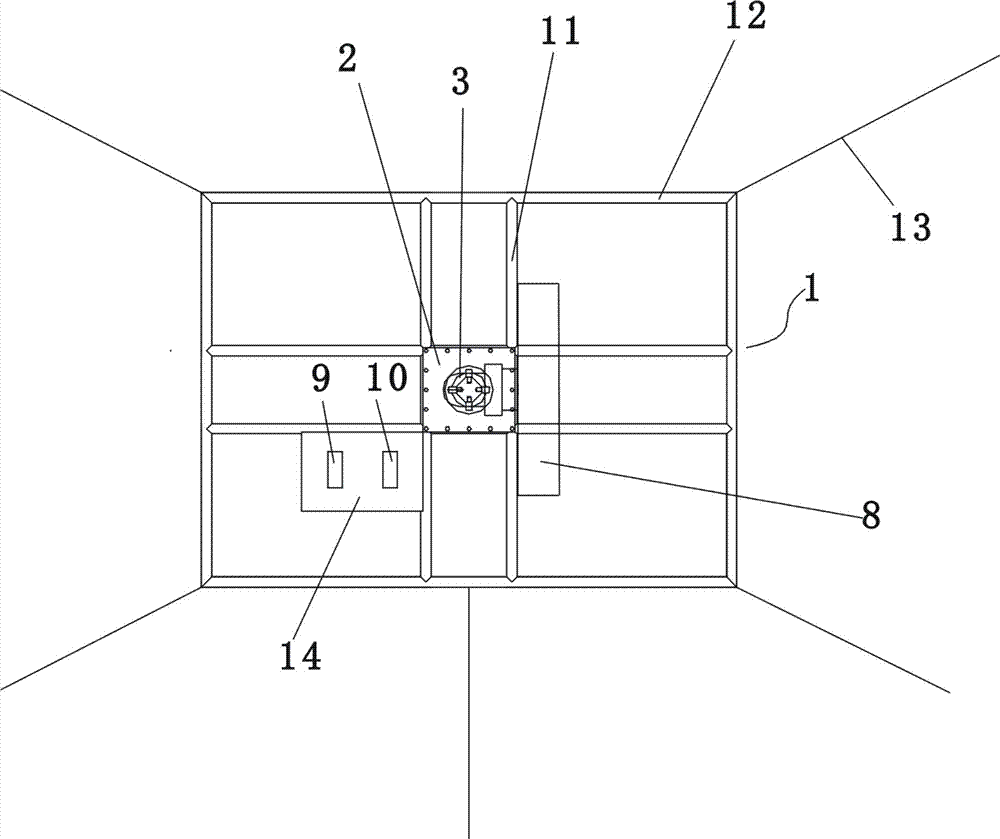

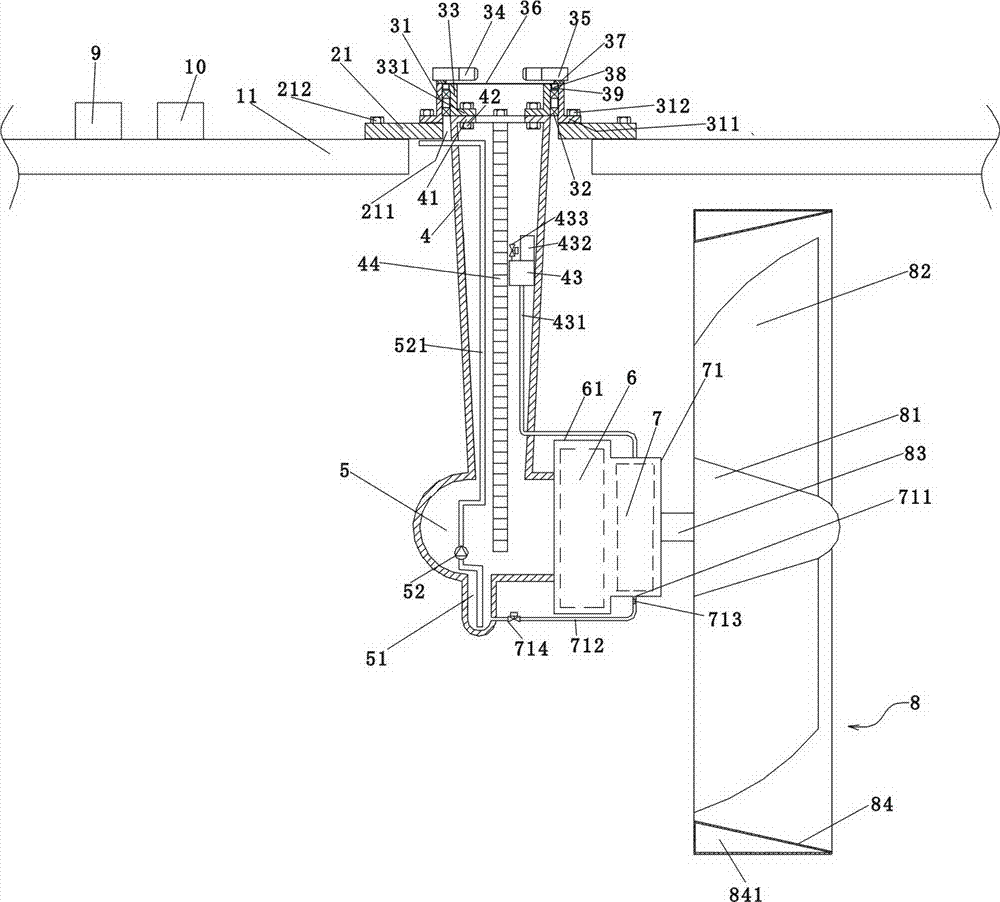

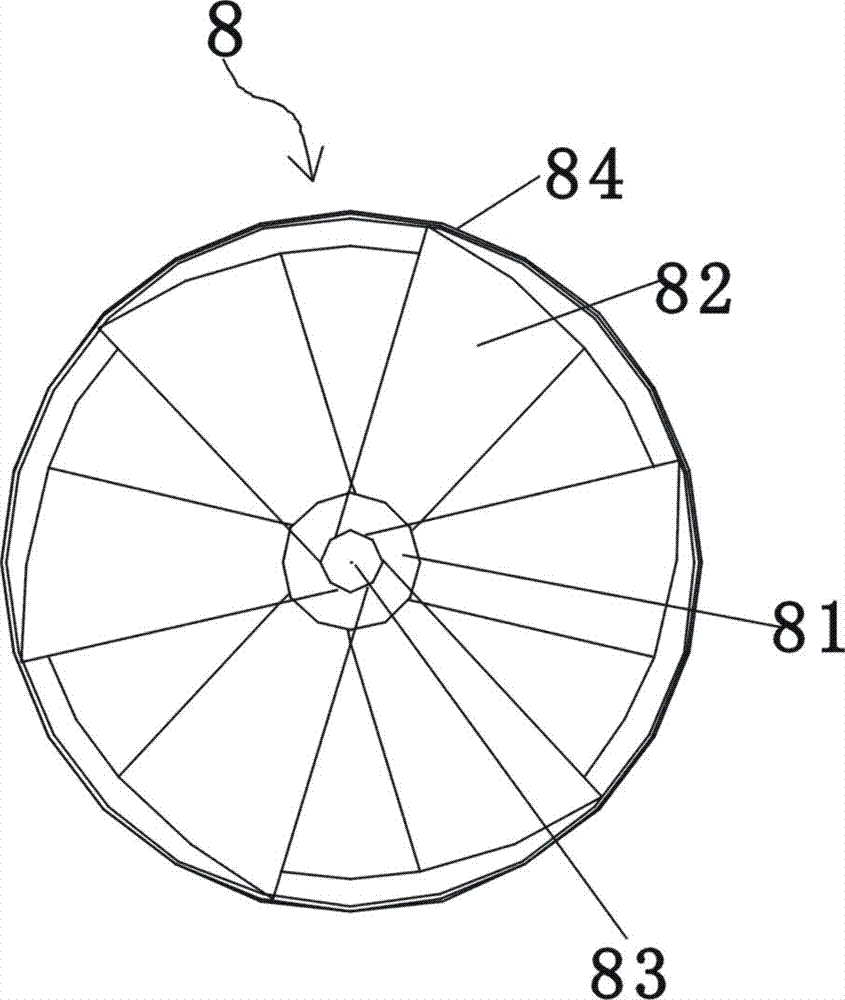

[0030] Such as figure 1 , 2 , 3, the water flow power generation device of the present invention includes a suspension frame 1, an installation platform 2, a rotating mechanism 3, a tower tube 4, a cabin 5, a generator 6, a gear box 7, an impeller 8, a control room 9 and a transformer 10;

[0031] The suspension frame 1 includes a "well" frame formed by welding several built-in buoys 11 and a square frame surrounded by several external buoys 12. One end of the center of the "well" frame is fixed on the side wall of the external buoy, and each of the four corners of the square frame is connected with a set of pull ropes 13 and ground anchors, and the ground anchors are placed on the underwater ground to make the frame fixed and float on the water surface superior;

[0032] The installation platform 2 is a square metal plate 21, and the center of the metal plate is provided with a round hole 211 for the upper end of the tower to pass through, and the outer edge of the metal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com