Spiral thrust mechanism of continuously variable transmission (CVT) for electrically adjusting reducing of driving wheel and method

A continuously variable speed, driving wheel technology, applied in mechanical equipment, transmission, transmission parts and other directions, to achieve the effect of convenient operation, low production cost, easy to promote and popularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

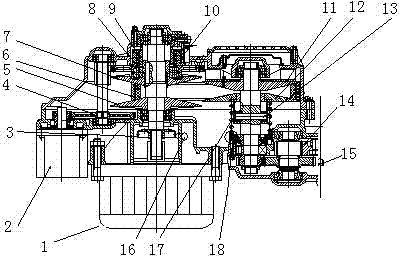

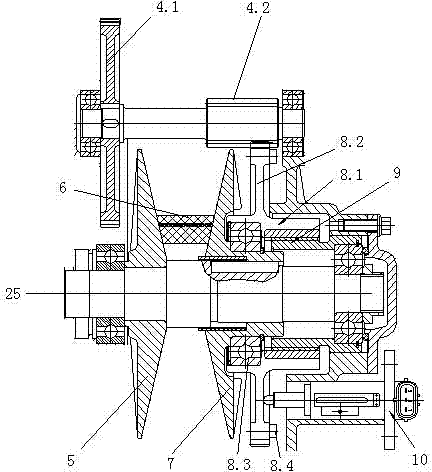

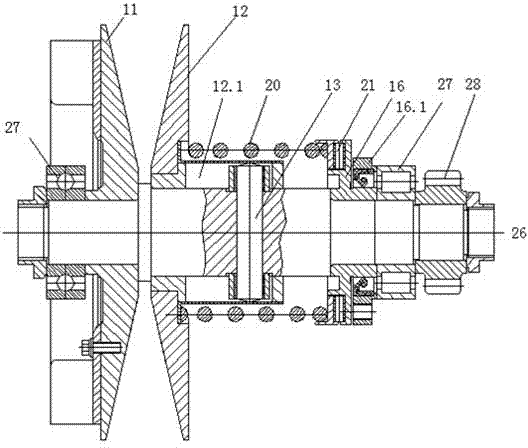

[0030] Such as Figure 1 to Figure 7 As shown, a helical thrust mechanism for electrically adjusting the diameter of the driving wheel of a continuously variable transmission, including: a speed-regulating gear 8 of the movable part and a helical thrust seat 9 of the fixed part, the internal thread arranged at one end of the speed-regulating gear 8 holes and the The external threads of the helical thrust seat 9 are connected with screws, and the helical thrust seat 9 is sleeved on the driving shaft through a bearing, and the outer ring of the helical thrust seat 9 is arranged in the shaft hole of the casing. The electronically controlled continuously variable transmission consists of: a box body, an electric speed-regulating drive device, a screw thrust device, a driving wheel transmission mechanism, and a driven wheel transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com