Pipeline inspection device based on rotating electromagnetic field

A pipeline detection and electromagnetic field technology, applied in the direction of material magnetic variables, etc., can solve problems such as pipeline failures, interference signals, and complex system design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

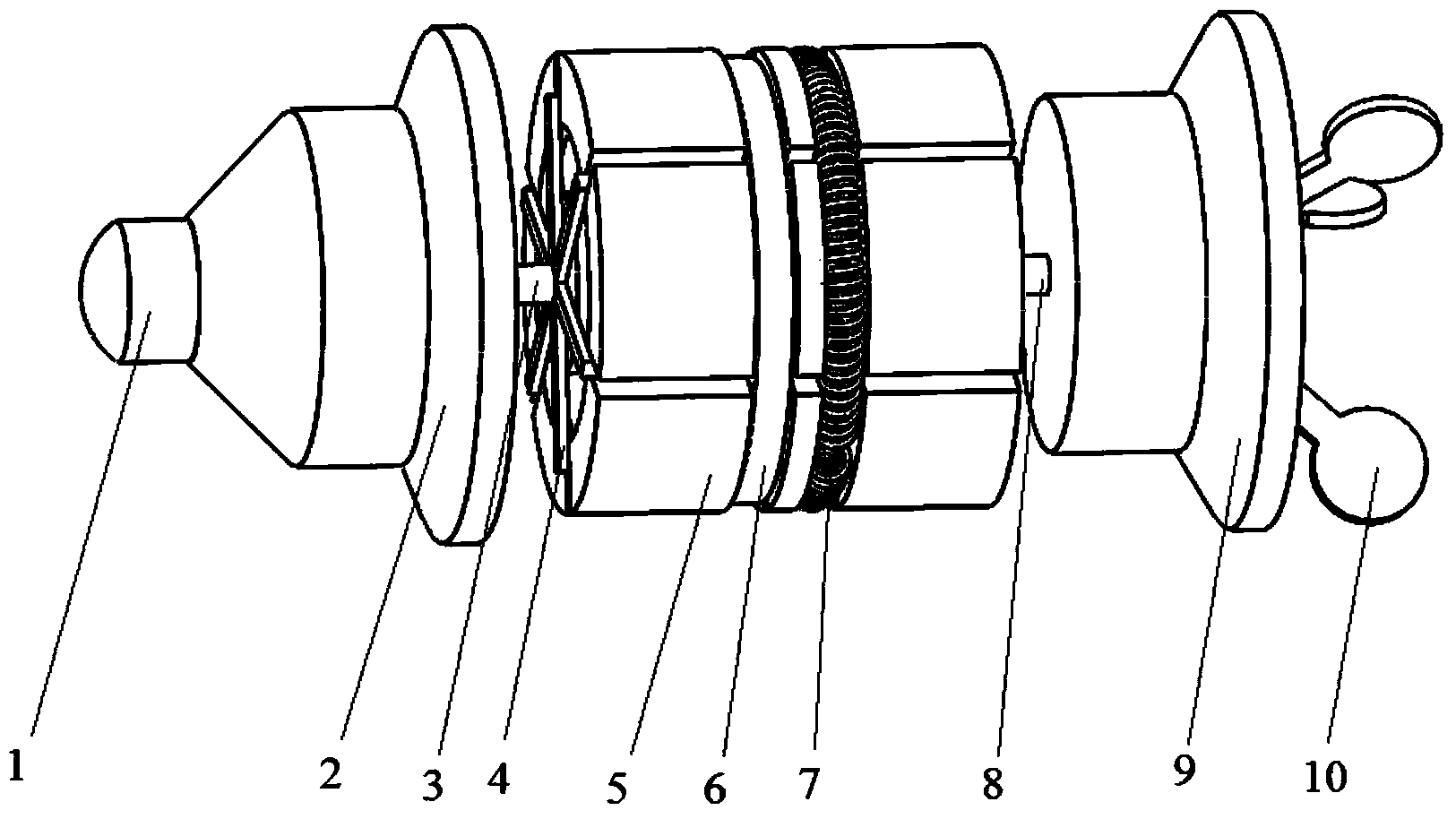

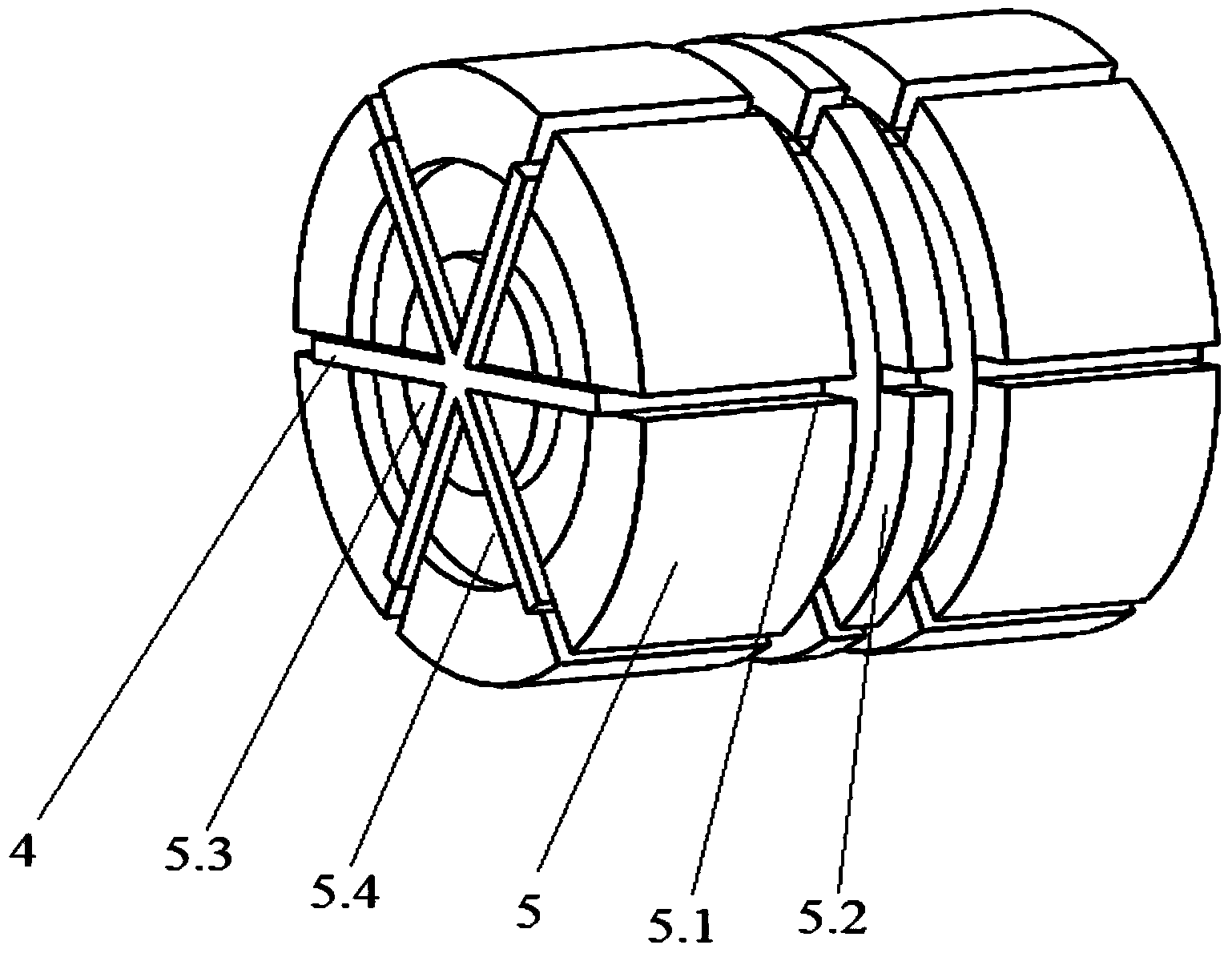

[0012] combined with Figure 1-4 The present invention is further described:

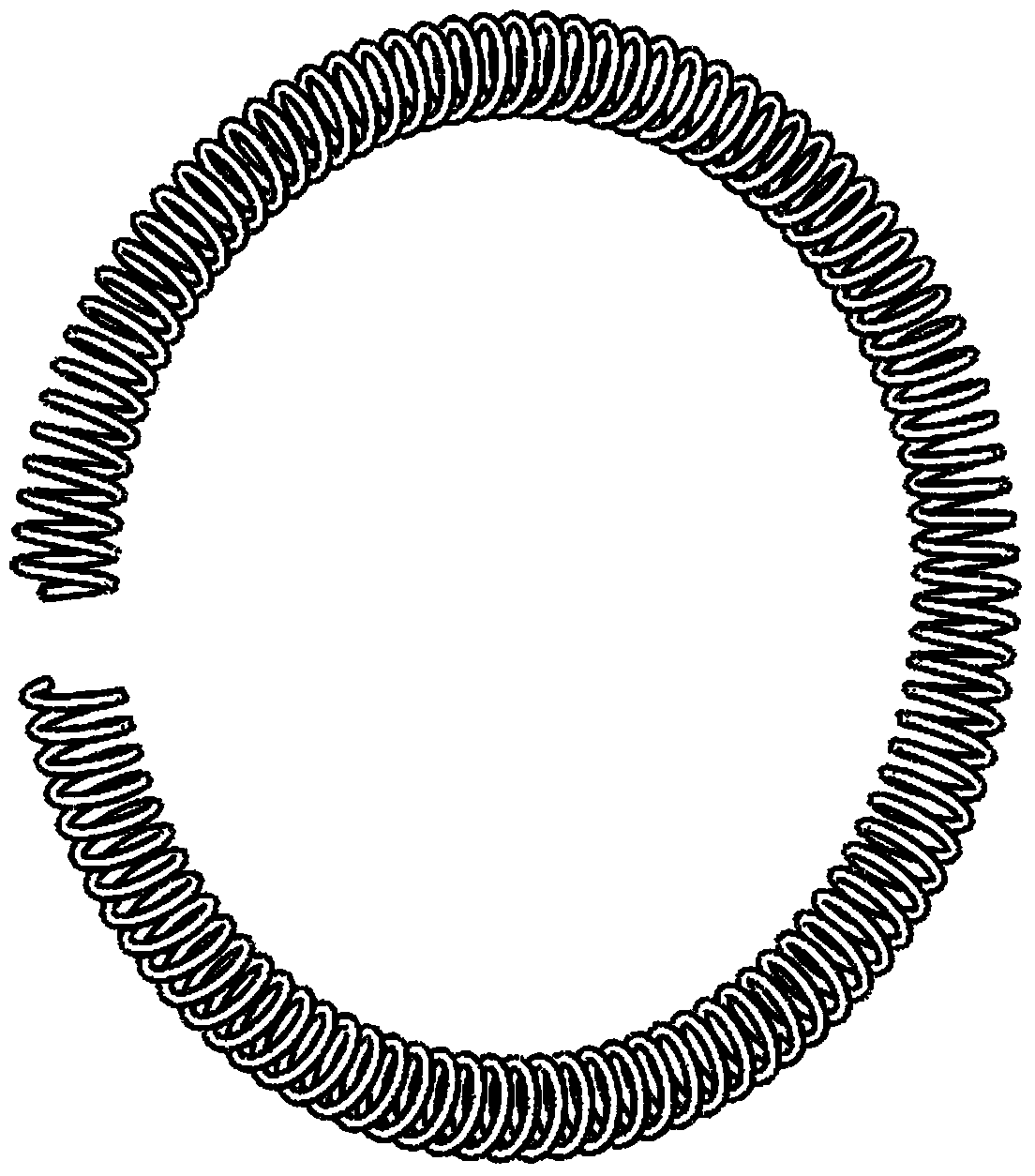

[0013] The present invention mainly consists of a navigator 1, a cleaning cup 2, a flexible joint A 3, an excitation coil 4, a skeleton 5, an axial detection coil 6, a tangential detection coil 7, a flexible joint B 8, a power cup 9 and a mileage Wheel 10, the navigator 1 and the cleaning cup 2 are fixed together, as the first section of the pipeline detection device, the navigator 1 is used for device positioning, the cleaning cup 2 is used for cleaning the inner wall of the pipeline, and the excitation coil 4 , the skeleton 5, the axial detection coil 6 and the tangential detection coil 7 form the second section of the pipeline detection device, and the power cup 9 and the mileage wheel 10 are installed together as the third section of the pipeline detection device. The fluid inside the pipeline provides power for the detection device. The mileage wheel 10 is used to record the stroke of the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com