Laser temperature control circuit based on tec

A temperature control and laser technology, applied in temperature control, non-electric variable control, control/adjustment system, etc., can solve the problems of instability, bulky, expensive, etc., and achieve the effect of fast and stable temperature adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

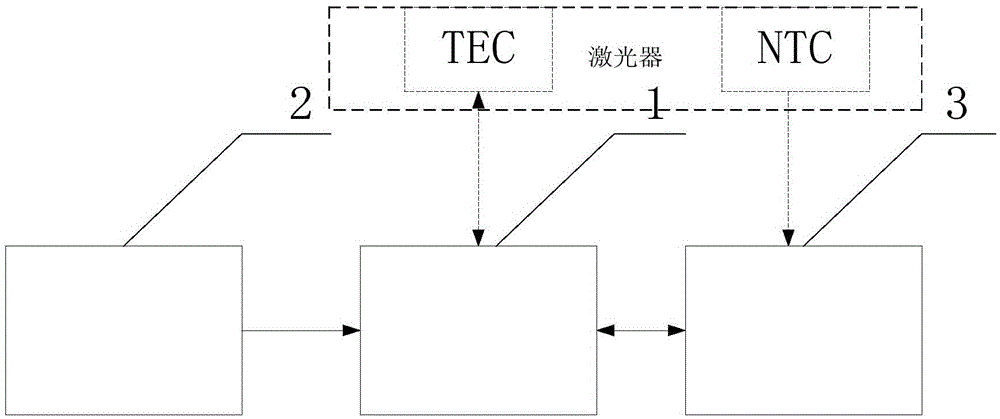

[0015] The invention includes a temperature control chip circuit 1 , a power supply circuit 2 and a Wheatstone bridge circuit 3 .

[0016] like figure 1 As shown, the power supply circuit 2 provides +5V power input for the temperature control chip circuit 1 . The temperature control chip circuit 2 controls the direction and magnitude of the peripheral TEC current, and receives the feedback signal from the Wheatstone bridge circuit 3 . The NTC provides a temperature-varying feedback resistance for the Wheatstone bridge circuit 3 .

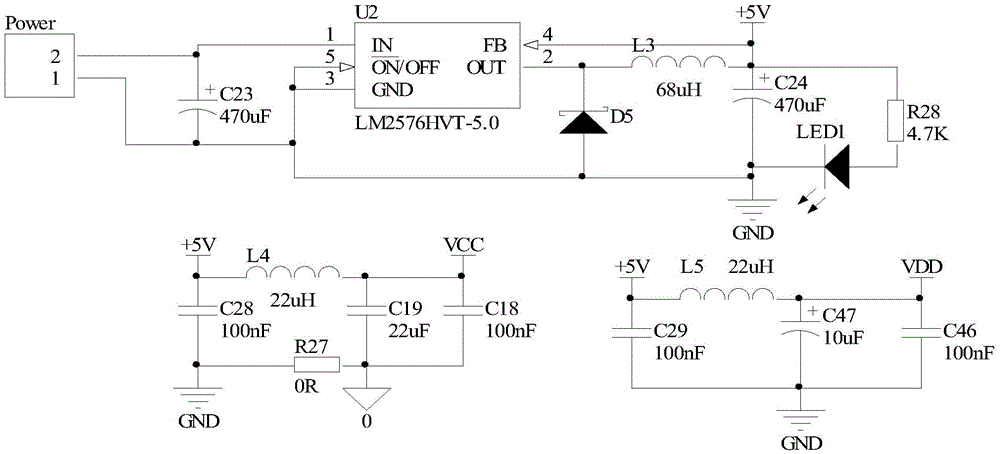

[0017] like figure 2 As shown, the power supply circuit includes a power conversion chip IC2, 2 electrolytic capacitors C23 and C24, 2 tantalum capacitors C19 and C47, a voltage regulator tube D5, a light-emitting diode LED1, 4 ceramic capacitors C18, C28, C29 and C46, 3 power inductors L3, L4 and L5, resistors R28 and R27. Pin 1 of the power conversion chip IC2 is the input terminal, which is connected to the positive pole of the electrolytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com