Ice melting power triangle based ice coating lead ice melting current obtaining method

A technology of power triangle and ice melting current, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of calculation method error, poor engineering applicability, etc., to achieve small calculation error, strong engineering applicability, parameter Calculate simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

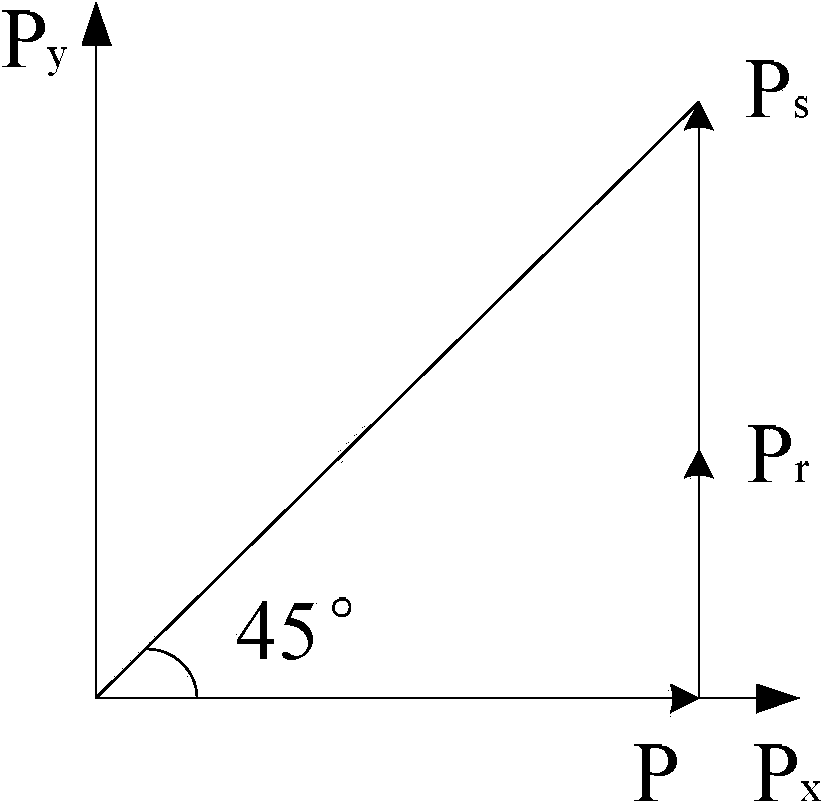

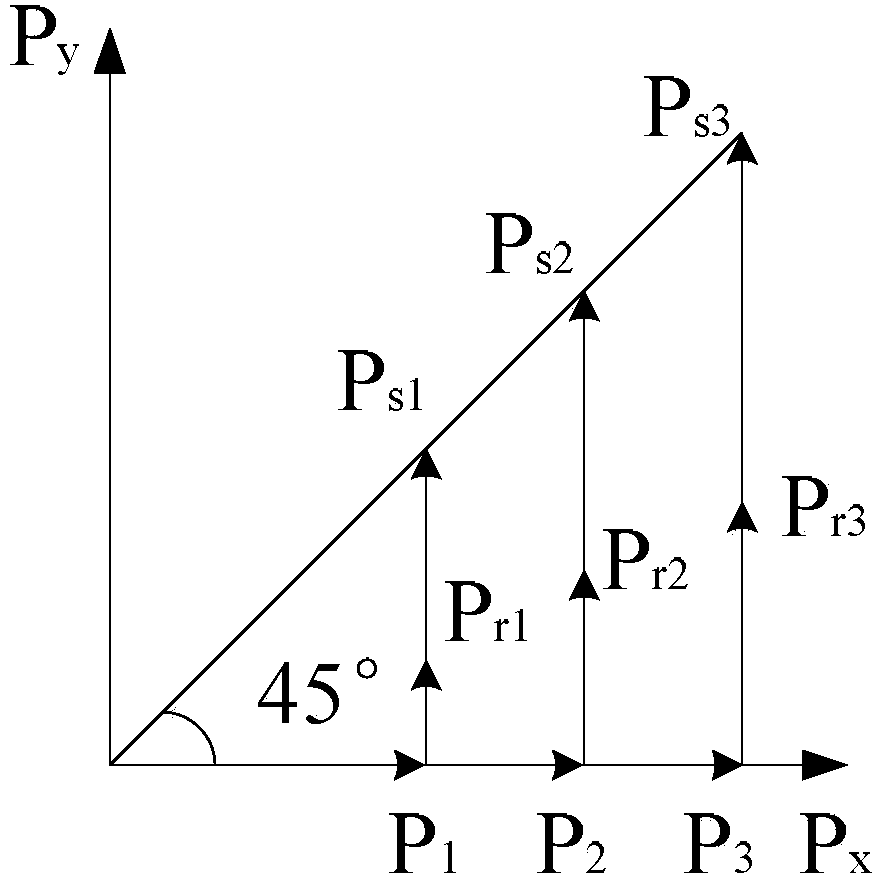

[0080] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the method for obtaining the ice-melting current of an ice-coated conductor based on the ice-melting power triangle described in this embodiment includes the following steps:

[0081] Step 1. Establish ice-melting power triangle

[0082] In the plane Cartesian coordinate system P x OP y An isosceles right-angled triangle is established in the interior, and this isosceles right-angled triangle is the described ice-melting power triangle, and the three apex coordinates of this ice-melting power triangle are respectively (0, 0), (P, 0) and (P, P r +P s ), where P is the input power for melting ice, P r Absorbed power for icing, i.e. the total power needed to heat up and melt the icing body, P s for wire heating and ambient loss power, then

[0083] Step 2. Set P Q is the initial power, and 0Q x Take a point on the axis (P Q , 0), from the point (P Q ,0), (P,0) and (...

specific Embodiment approach 2

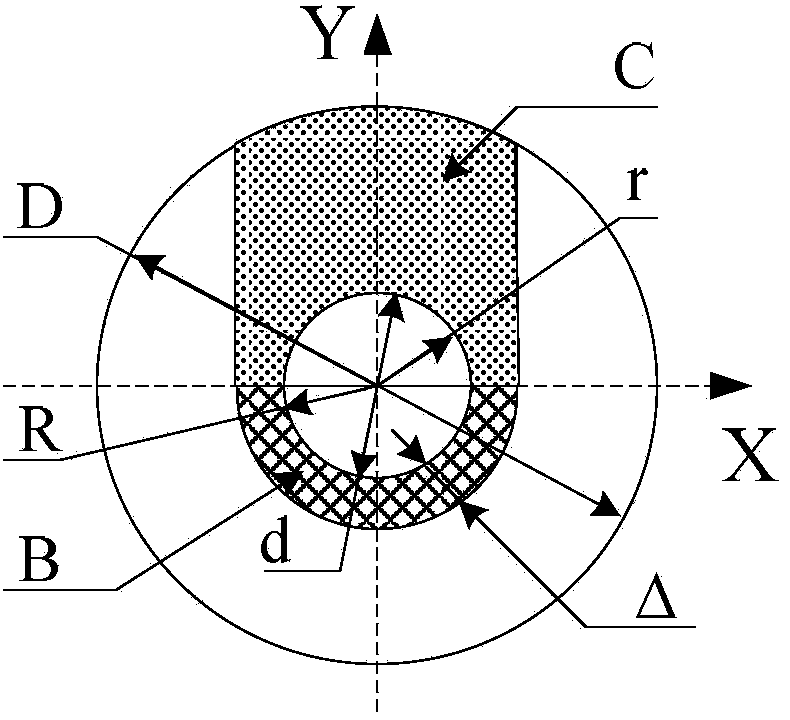

[0109] Specific implementation mode two: combination image 3 This embodiment is described. This embodiment is a further limitation of the method for obtaining the ice-melting current of the ice-coated conductor based on the ice-melting power triangle described in Embodiment 1. In this embodiment, the V s is calculated by the following formula:

[0110] V s =0.7854(D+d)(D-d) (25)

[0111] Among them, D is the diameter of the ice-covered body, and d is the diameter of the wire, such as image 3 shown.

specific Embodiment approach 3

[0112] Specific implementation mode three: combination image 3 This embodiment is described. This embodiment is a further limitation of the method for obtaining the ice-melting current of the ice-coated conductor based on the ice-melting power triangle described in Embodiment 1. In this embodiment, the V 3 is calculated by the following formula:

[0113] V 3 = B + C B = π ( r + Δ ) 2 - πr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com