Jet pumps for hot chamber die casting of corrosive light alloys

A hot-chamber die-casting, jet pump technology, applied in the field of jet pumps, can solve problems such as deterioration of sealing surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

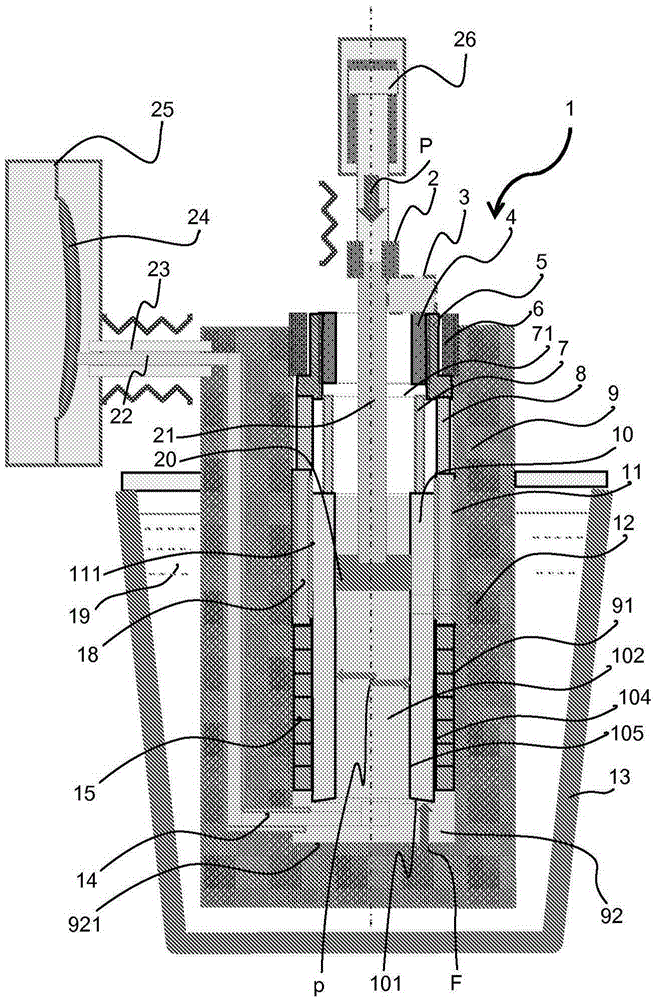

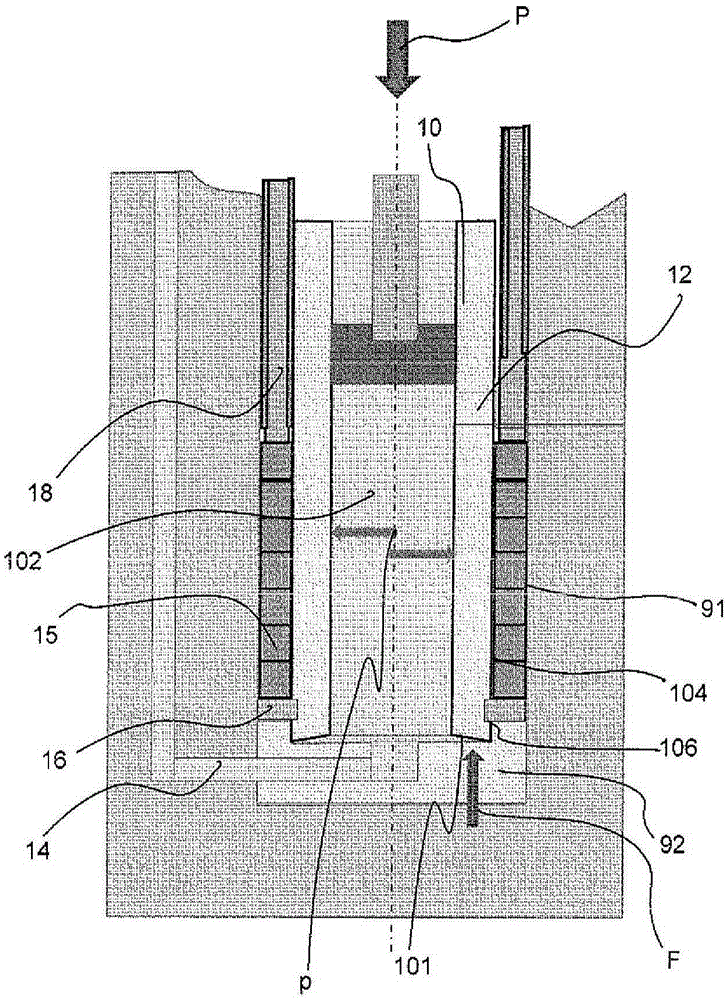

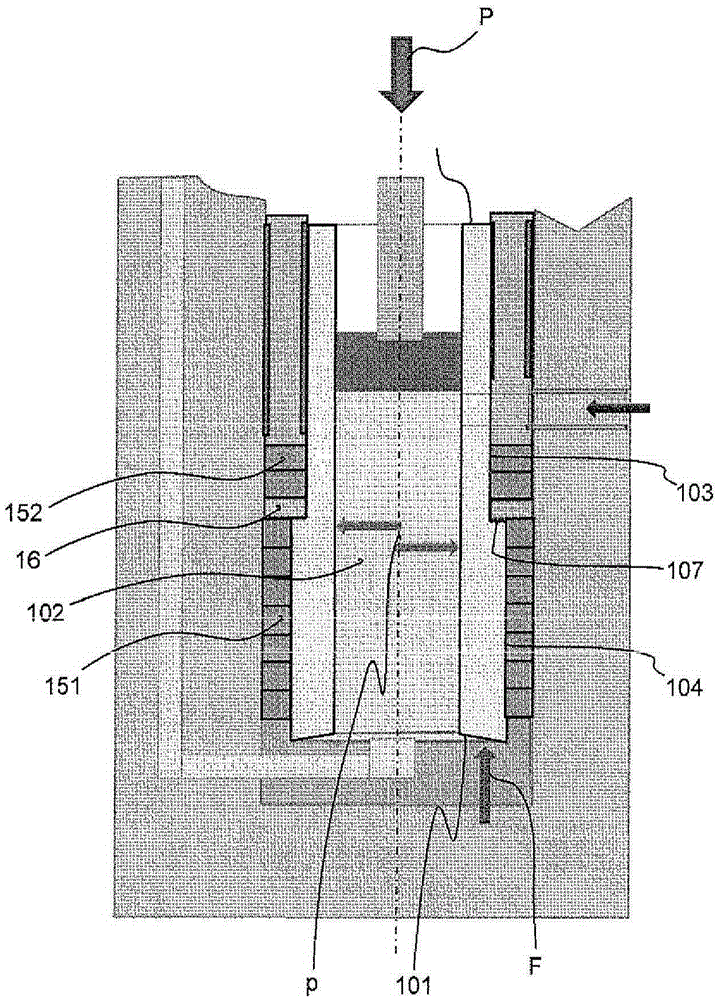

[0033] refer to figure 1 , it can be seen that the hot chamber jet pump 1 according to the invention generally comprises a body 9 inserted into a crucible 13 and provided with an inner bush 10 coaxial therewith, the injector piston 20 being driven by an actuator 26 through a rod 21 slides in the inner bushing 10 in a reciprocating manner. The piston 20 has the function of pushing and compressing the molten alloy 19 into a cavity 24 of a mold 25 connected to the pump 1 through a conduit 22 provided with an external heating jacket 23, the molten alloy 19 being present under the piston 20 by The inner volume of the bushing 10 forms the injection chamber 102 . Ejection chamber 102 is connected to conduit 22 by conduit 14 formed in body 9, and communicates with the chamber of crucible 13 by conduit 12, conduit 12 passing through liner 10 and body 9, during the return stroke of piston 20 alloy 19 is usually due to Gravity or suction enters the spray chamber 102 through the conduit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com