Machine tool and machining method

A technology of processing method and working method, which is applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of complicated structure of conveying line and difficulty in increasing conveying speed, so as to realize conveying efficiency, increase conveying speed, Realize the effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

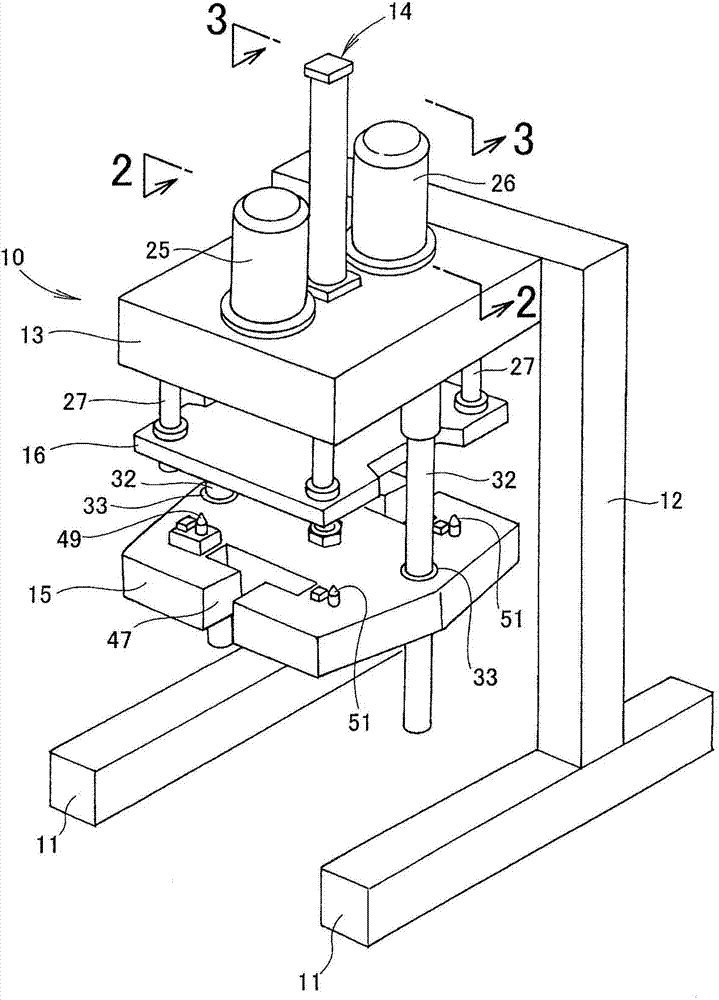

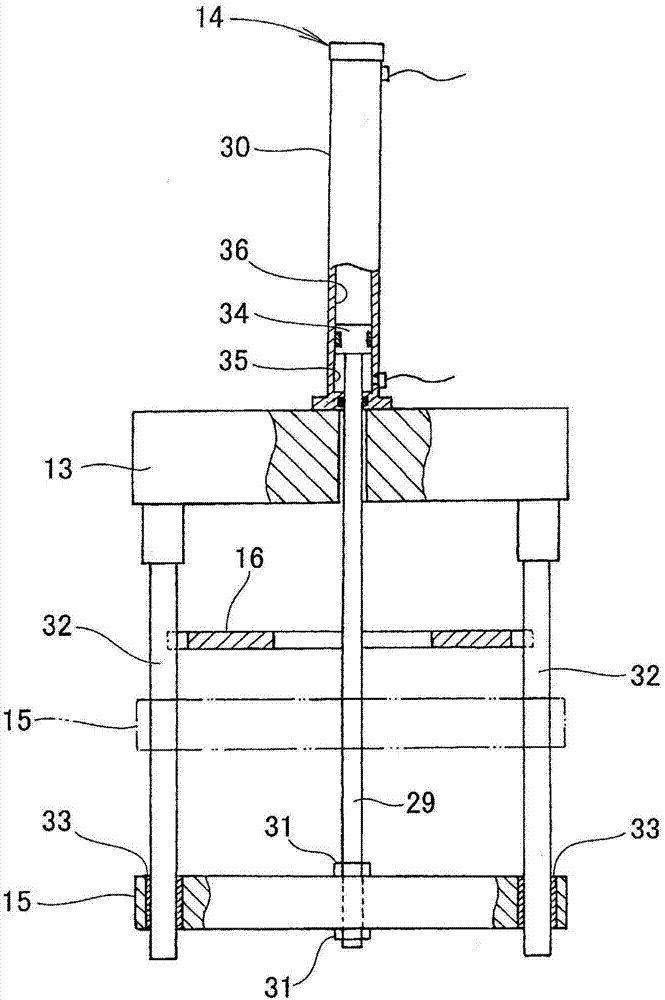

[0042] Such as figure 1 As shown, the machine tool 10 has: base frames 11, 11, which extend horizontally in a manner placed on a base or a chassis; an inverted U-shaped frame 12, which extends upward from these base frames 11, 11; a processing head 13, It is supported by the frame 12; a workpiece supporting plate moving mechanism 14, which is provided on the processing head 13; a workpiece supporting plate 15, which is moved up and down by the workpiece supporting plate moving mechanism 14; and a workpiece pressing plate 16, which is arranged on the processing head 13. Between the workpiece support plate 15 and the processing head 13.

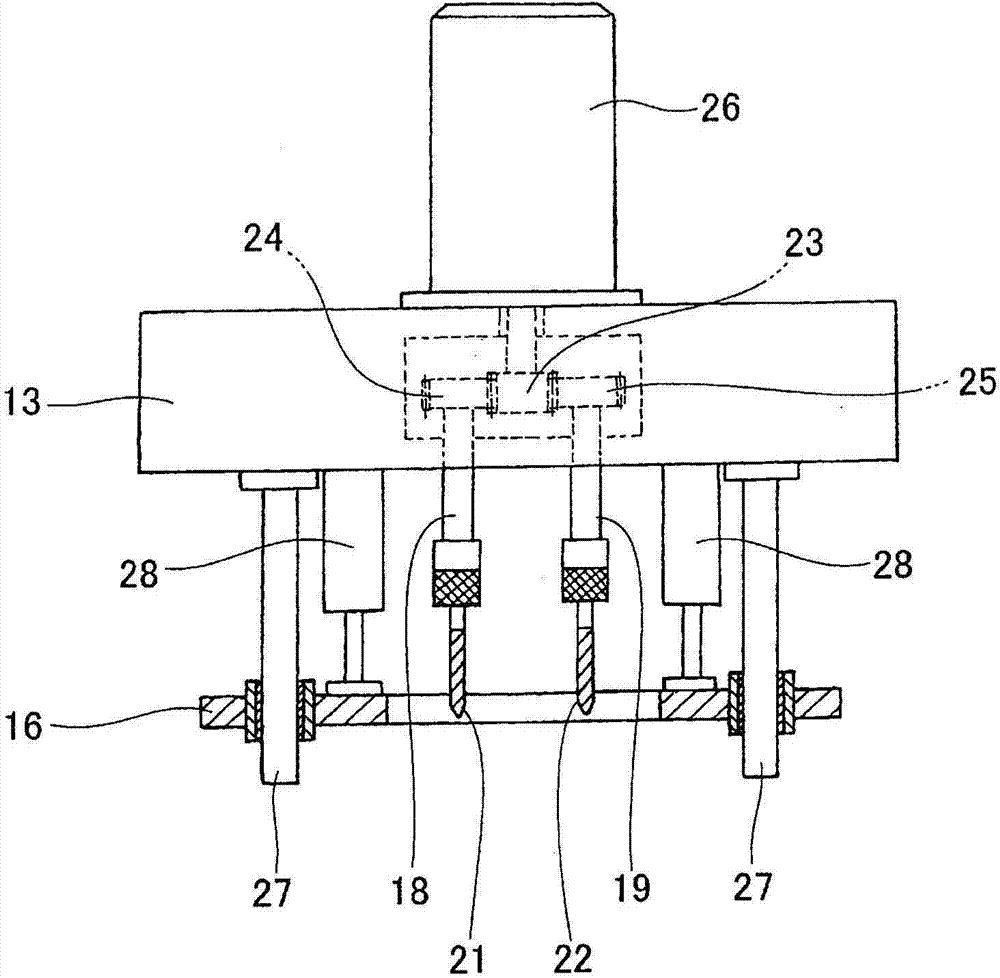

[0043] Such as figure 2As shown, the machining head 13 has a plurality (in this example two) of spindles 18, 19 extending downwardly. Cutting tools 21 , 22 such as drills and end mills are detachably attached to these spindles 18 , 19 .

[0044] A driving gear 23 and driven gears 24, 25 are built into the machining head 13, and the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com