Method of converting steam turbine - powered lng carriers

A technology of liquefied natural gas and steam turbine, applied in the direction of engine using steam turbine, steam engine, propulsion-based emission reduction, etc., to achieve the effect of great operation flexibility and fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

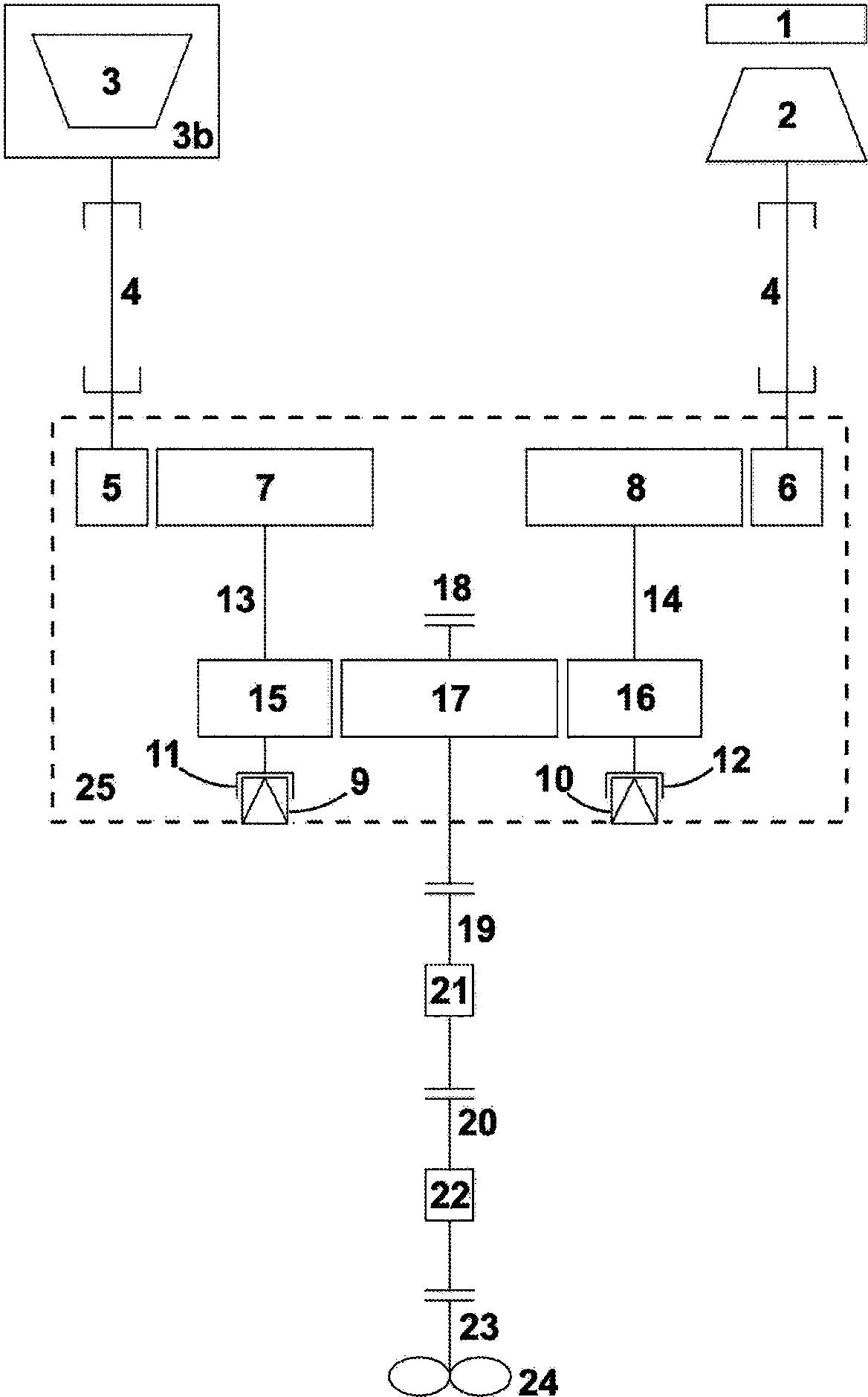

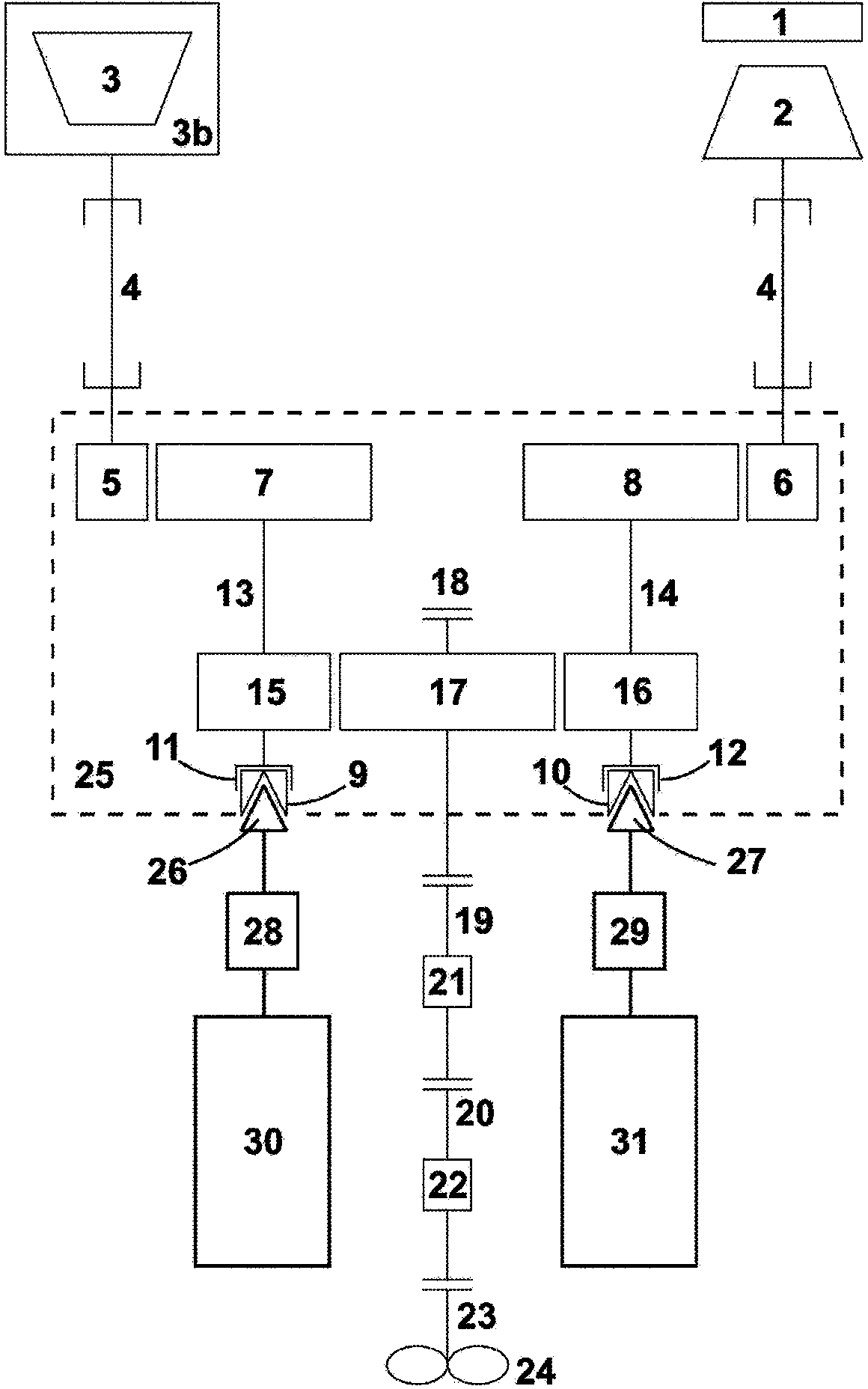

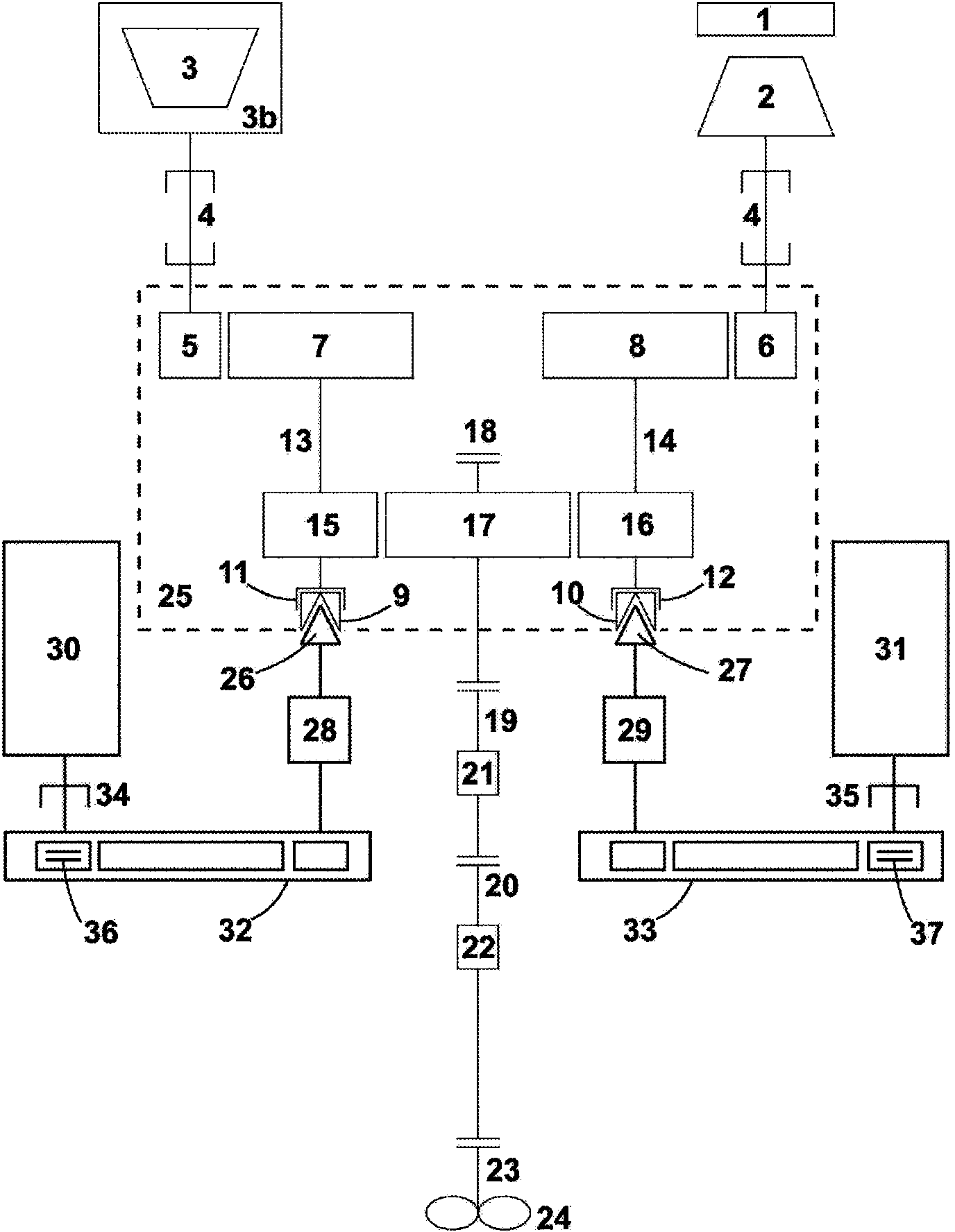

[0216] The method of converting a steam turbine powered LNG carrier, object of the present invention, basically comprises, as can be seen in the accompanying drawings, the addition of one or more generating sets (47), together with their auxiliary components (48, 49, 50 . The mechanical connection of the output shaft assembly (19, 20, 23) of the device to emit power. This mechanical power is introduced into the gearbox (25) or the existing output shaft assembly (19, 20, 23) through a specific method, maintaining the full operation of the existing steam turbine (2, 3) propulsion equipment, having the characteristics of It is to maintain the existing steam turbine propulsion equipment, so that the converted transport ship has diesel electric or turbine electric propulsion devices, combined with the aforementioned two steam turbine propulsion and hybrid propulsion devices. The output shaft assembly is understood to be the assembly mainly defined by the intermediate bow shaft (19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com