Method for dispensing a lubricant in a metered manner

A lubricant and reserve technology, used in lubricating parts, engine lubrication, dosing devices, etc., can solve problems such as dissatisfaction and inaccurate evaluation of lubricant dosage, and achieve the effect of improving distribution accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

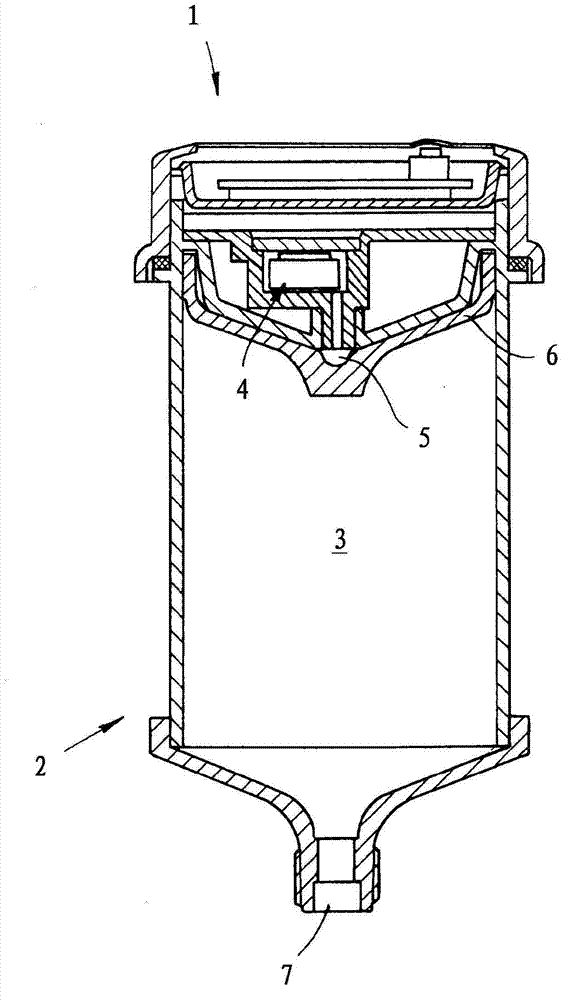

[0019] Control unit 1 and lubricant cartridge 2 belong to figure 1 The basic structure of the lubricant distributor shown in . Lubricant cartridge 2 is equipped with lubricant 3 in the inner chamber. Furthermore, the lubricant distributor includes at least one electrochemical gas generator unit 4 . The electronic control unit 1 regulates the current through the gas generator unit 4 and thereby controls the amount of gas generated therein. These gas quantities pass through the conduit into the chamber 5 behind the piston 6 which is arranged in the lubricant cartridge and delimits the lubricant reservoir by its side facing away from the chamber 5 . Due to the gas generation, an overpressure builds up in the chamber 5 , which is transmitted by the piston 6 to the lubricant. As a result, lubricant 3 is squeezed out of lubricant cartridge 2 and exits the lubricant cartridge through opening 7 .

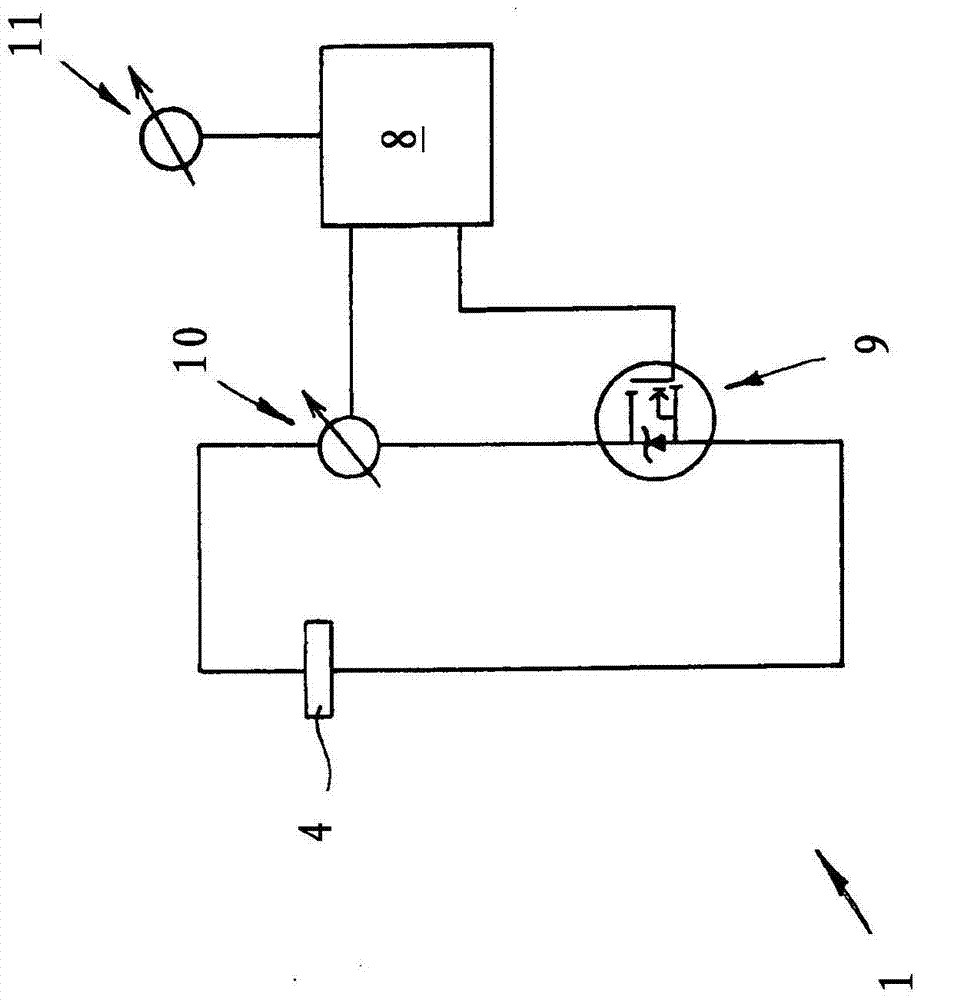

[0020] exist figure 2 A possible configuration of the circuit diagram of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com