Structure for dispersing chemical resin

A technology for dispersing structure and resin, applied in chemical instruments and methods, chemical/physical processes, mixers with rotating containers, etc., can solve the problems of not easy to lift, easy precipitation of resin, long time consumption, etc., to improve the extrusion force. , the effect of increasing the contact area and improving the dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

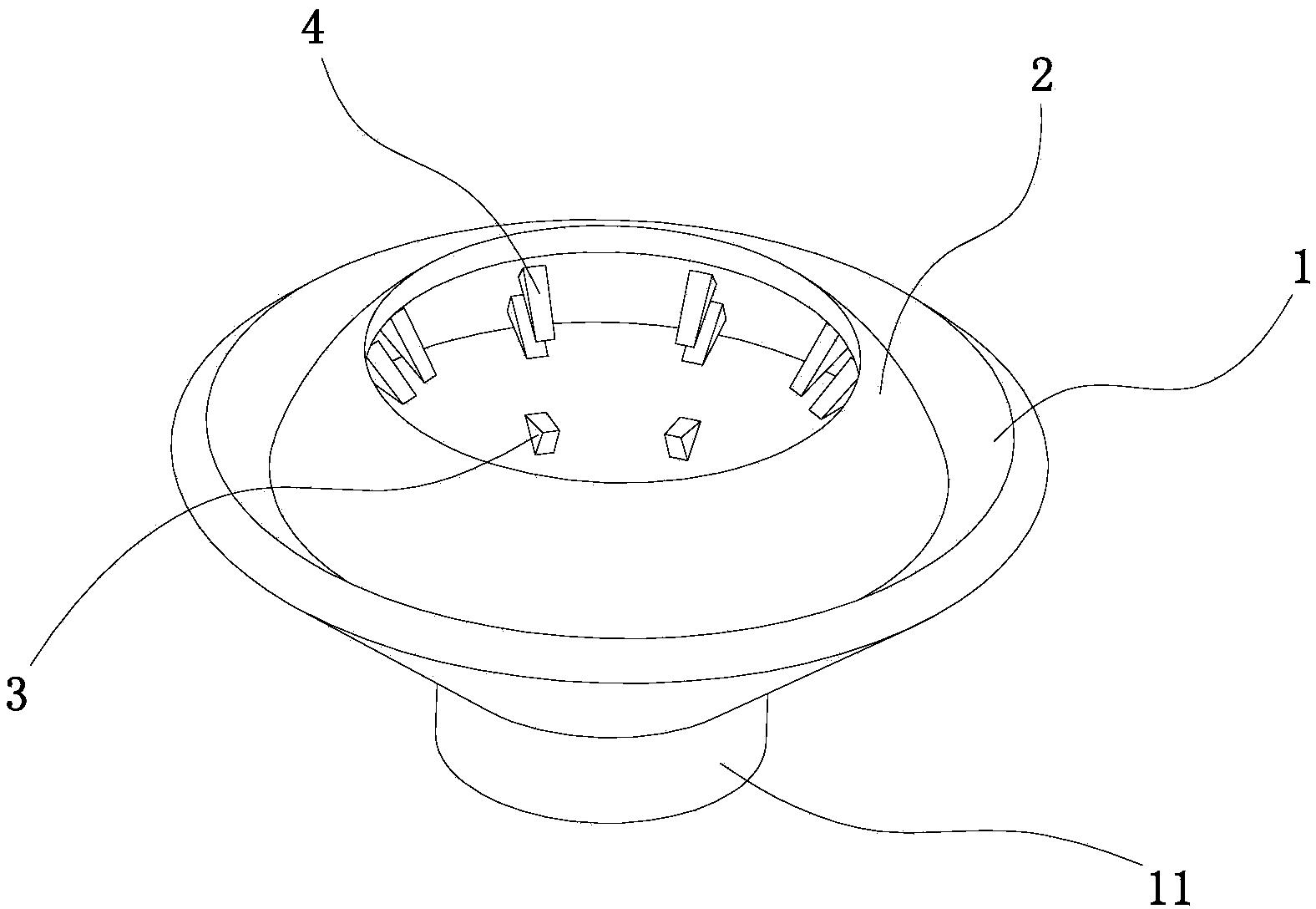

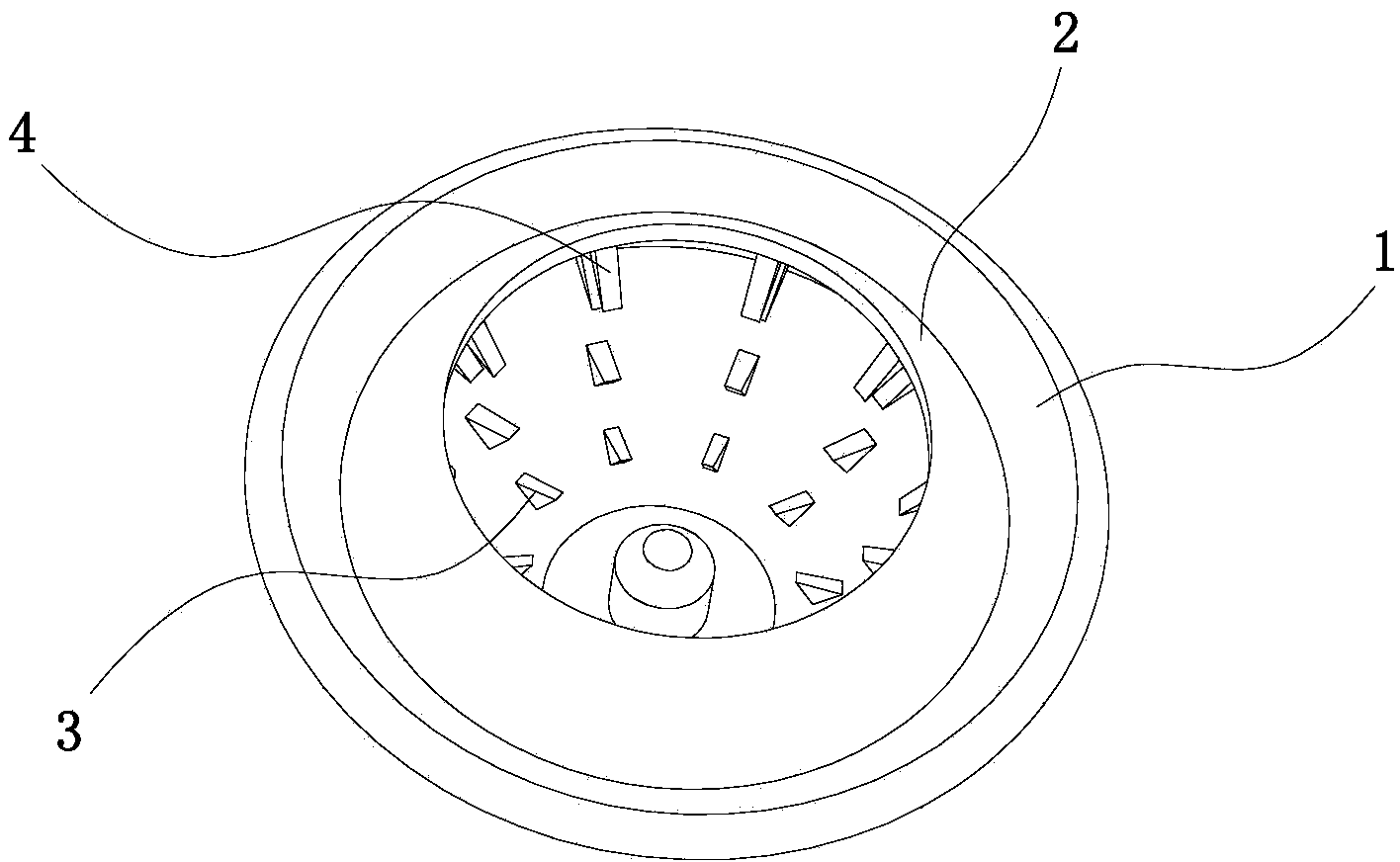

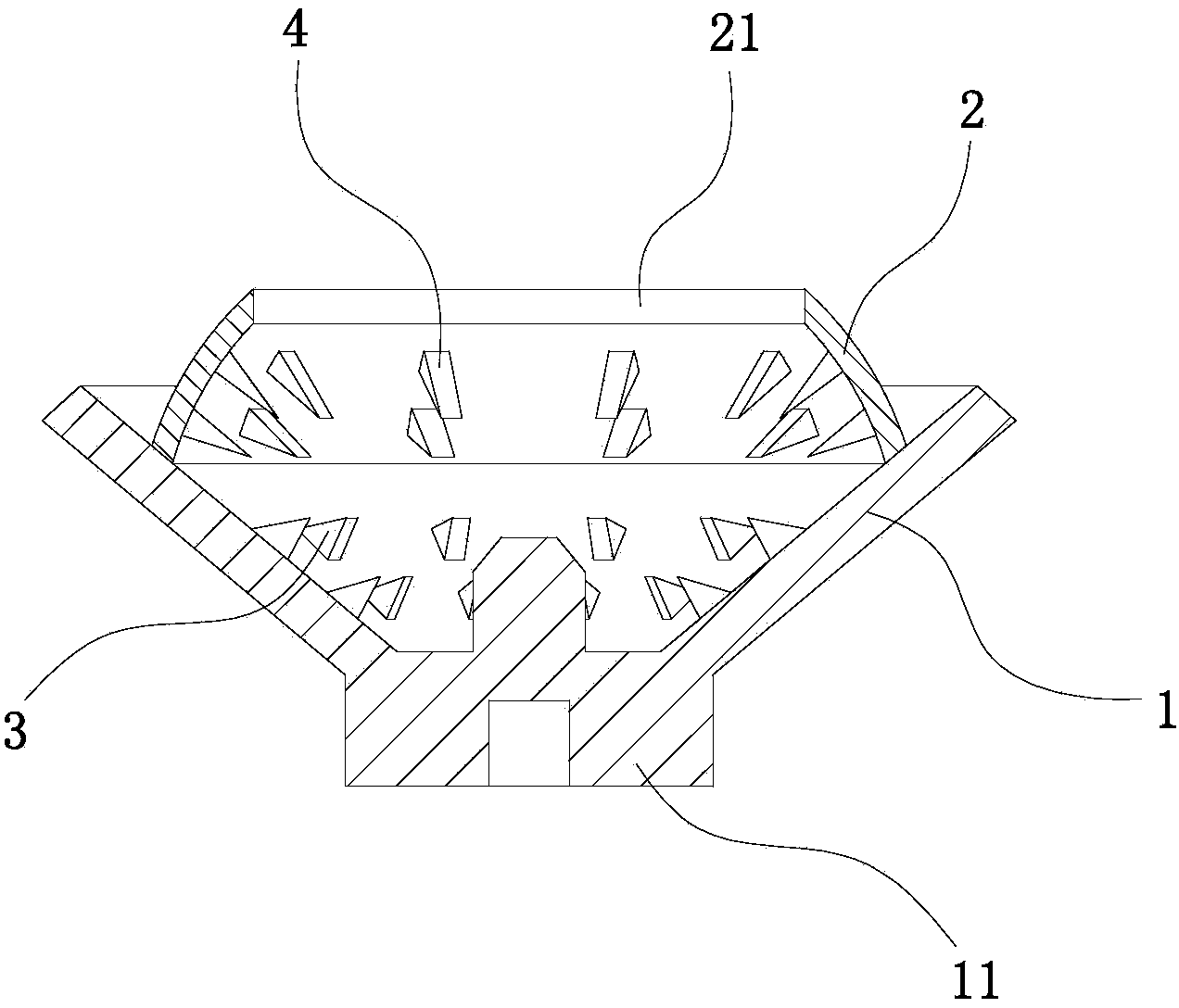

[0013] See figure 1 , figure 2 and image 3 , the dispersed structure of the chemical resin of the present embodiment comprises the rotary seat 1 of conical shell structure, and the rotary seat 1 is fixedly connected with the rotary driving device (not shown) by the base 11 at its bottom; the inner wall of the rotary seat 1 is fixedly connected There is a cover 2, the cover 2 is a boss-shaped shell structure with a through hole 21 on the upper end; the inner wall of the rotating seat 1 is arranged with a plurality of lower dispersing teeth 3, and the inner wall of the cover 2 is arranged with a plurality of upper dispersing teeth 4, The tooth tips of the lower dispersing teeth 3 and the upper dispersing teeth 4 respectively face the center of the rotating base 1, and the upper and lower dispersing teeth are combined to disperse and mix ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap