Quick cooling die for aluminum pistons produced through gravity casting

A rapid cooling and gravity casting technology, which is applied in the field of rapid cooling molds for gravity casting aluminum pistons, can solve problems such as slow cooling, achieve the effects of reducing production costs, accelerating solidification, and shortening preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

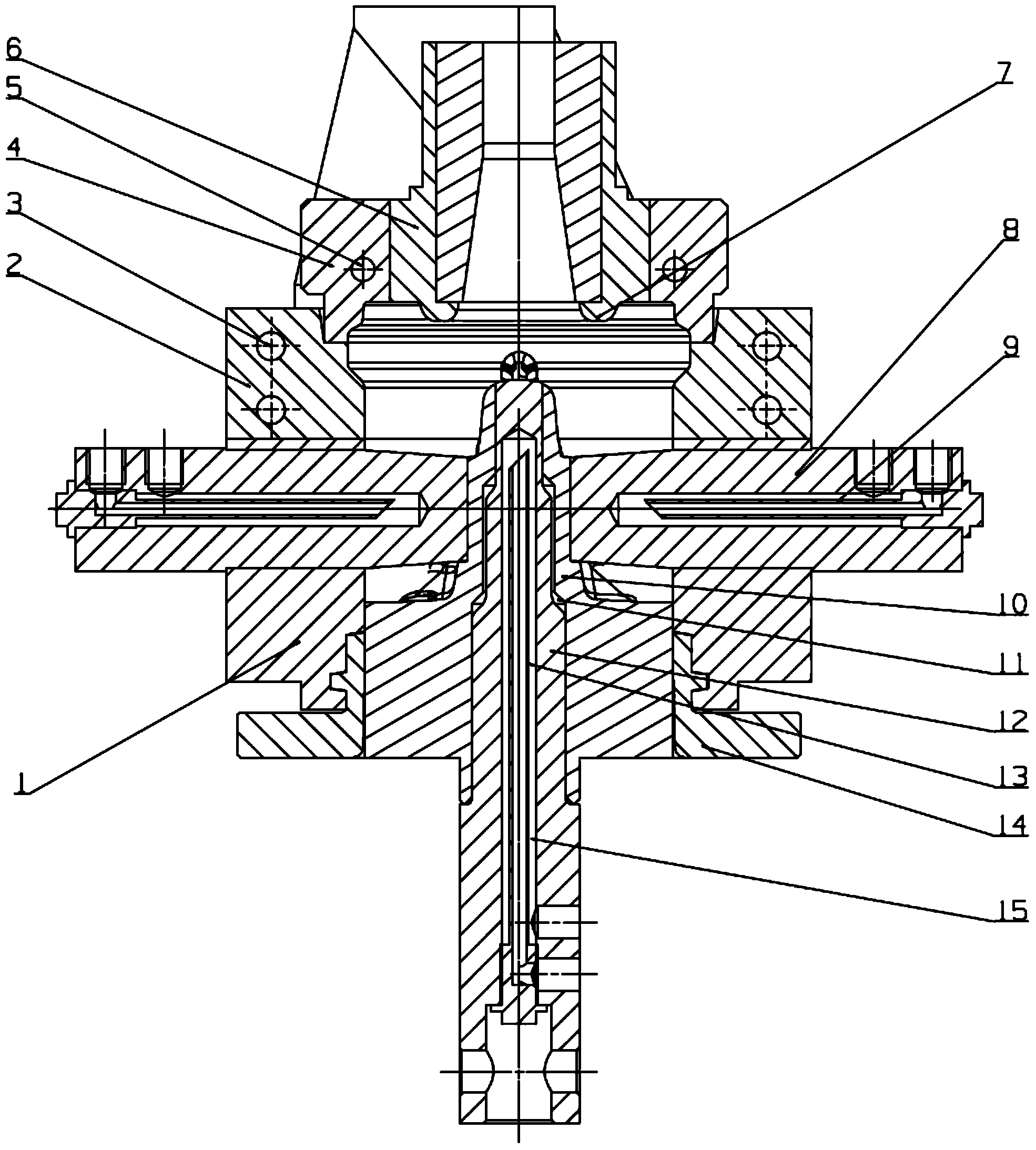

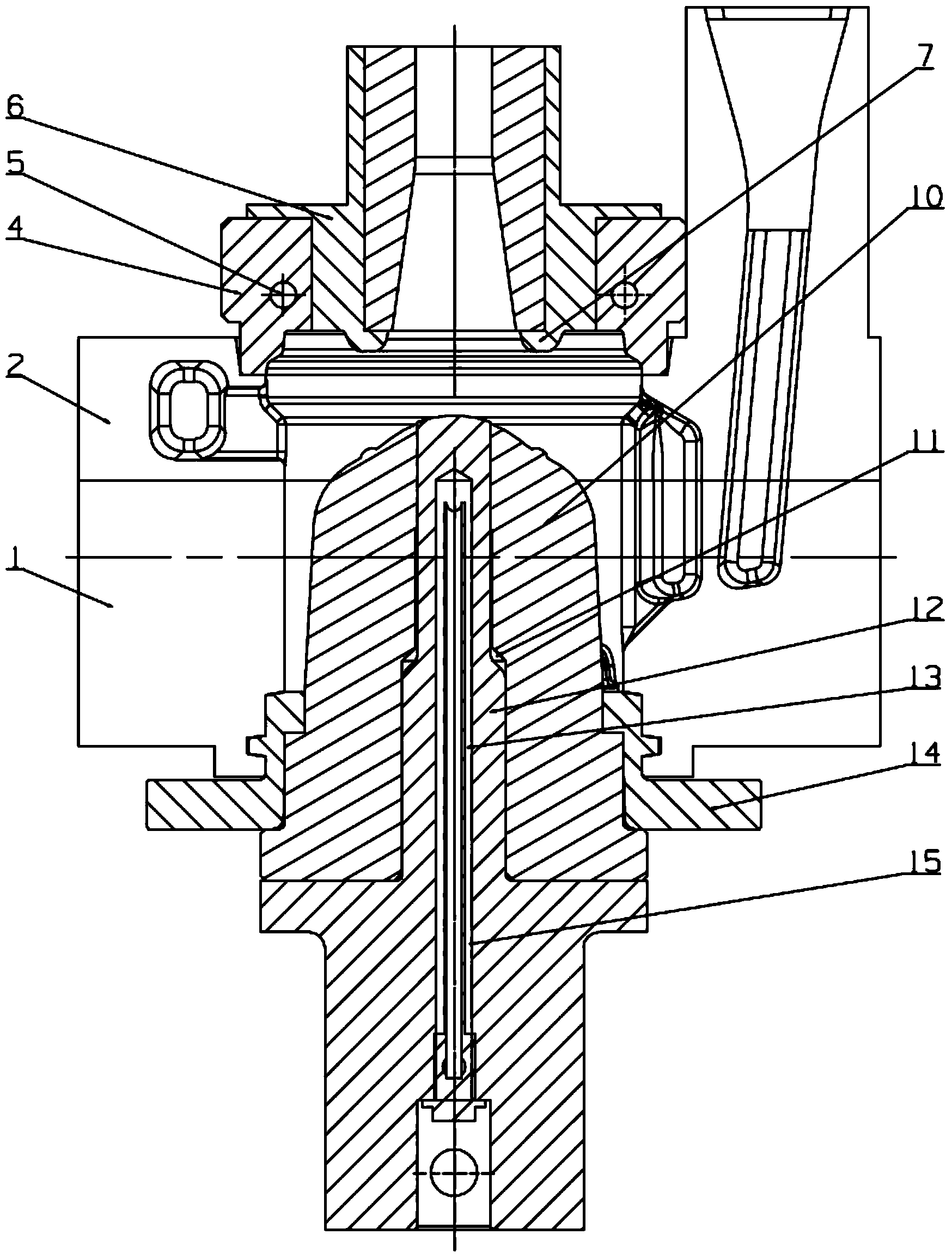

[0018] Such as figure 1 and figure 2 As shown, the gravity casting aluminum piston rapid cooling mold is mainly composed of outer mold, inner core, top mold, lip ring 14 and pin core 8; the outer mold is composed of outer mold lower block 1 and outer mold upper block 2 Outer mold cooling channel 3 is arranged in the upper block 2 of the outer mold; there is a top mold matched with it on the top of the upper block 2 of the outer mold, and a top mold cooling channel 5 is also arranged on the top mold, which is installed horizontally on the lower block of the outer mold Pin core 8, said pin core 8 is provided with a pin core cooling channel 9, between the left and right two pin cores 8 there is an inner core closely matched with it, and a cooling channel is provided inside the inner core; except the top mold Outside the cooling passage 5, all cooling pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com